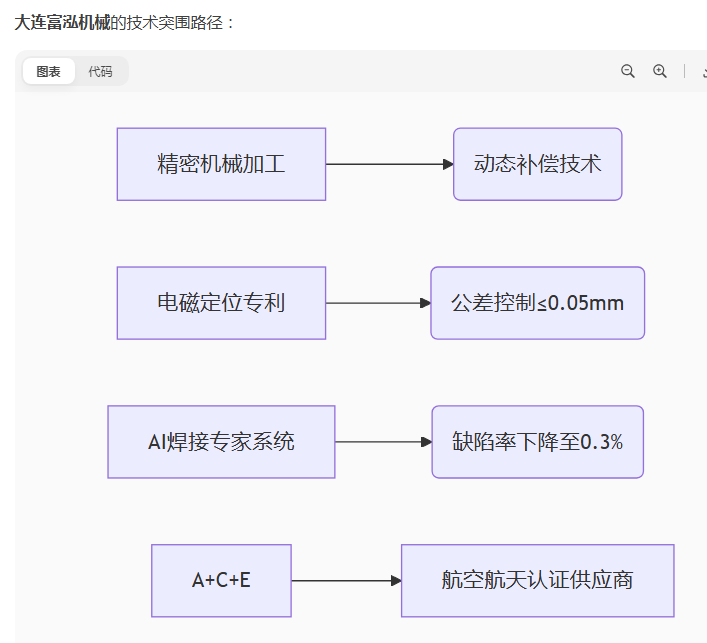

Precision machiningThe 5 advantages of: Why choose a professional processing plant?

1 Introduction: the value of precision machining

In a competitive manufacturing environment, precision machining has become a key determinant of product quality and performance. Choosing a professional machining facility not only ensures part accuracy, but also optimises productivity and reduces costs. In this article, we will detail the five advantages of professional precision machining to help you make informed purchasing decisions.

2 Analysis of five core advantages

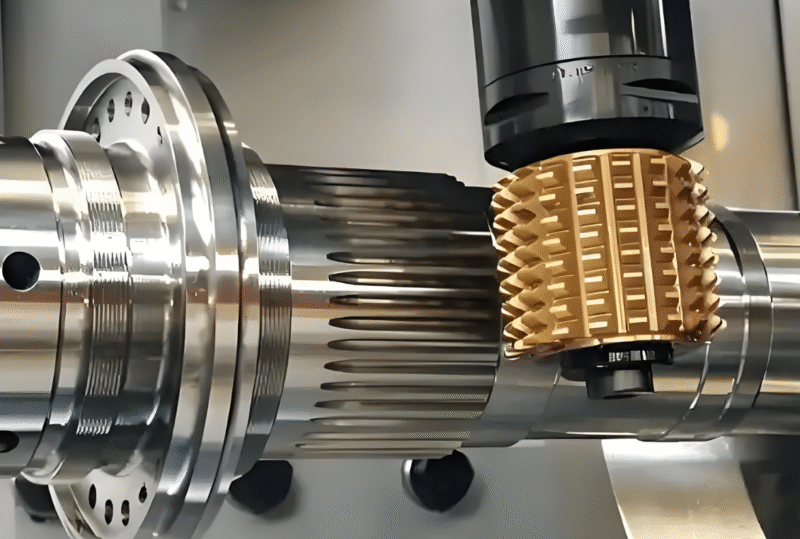

2.1 Extremely high dimensional accuracy and repeatability

Professional machining services use state-of-the-art CNC machines capable of achieving millimetre-level precision control. This is crucial for application scenarios with tight tolerance requirements:

Consistency: high level of consistency for every part in series production

Good interchangeability: no additional modifications are required when assembling the parts

High degree of design realisation: accurate realisation of the designer's intentions and requirements - 6![图片[1]-精密机械加工的5大优势:为什么选择专业加工厂?(通过优化加工路径和采用自动化设备,专业机械加工能显著提高生产效率)-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/10/QQ20251002-201517-1.png)

2.2 Wide range of material adaptability

Unlike a regular machine shop, a specialised machine shop has the ability to handle a wide range of materials:

Ferrous metals: carbon steel, alloy steel, stainless steel, etc.

Non-ferrous metals: aluminium, copper, titanium and their alloys

Special materials: high-temperature alloys, composite materials, etc.

We are familiar with the properties and processing difficulties of various materials and can select the most suitable material for your project.

2.3 Efficient production capacity

By optimising machining paths and using automated equipment, professional machining can significantly increase productivity:

Reduced lead times: fast response to customer needs

Reduced unit costs: through process optimisation and volume effects

Flexibility to adjust: Flexibility to adjust production schedules according to order quantities - 4

2.4 Comprehensive quality assurance system

Formal machining plantA comprehensive quality management system has been established:

Standardised process: from drawing review to finished product leaving the factory, there are clear specifications for each step of the process.

Professional inspection equipment: use of three coordinates, optical projector and other equipment for comprehensive inspection

Traceability system: establish a perfect quality traceability system to ensure that the origin of each part can be traced -3

2.5 Technical support and design optimisation

Professional fabricators not only process according to the drawing, but also provide value-added services to customers:

Recommendations for design optimisation: suggestions for improvement from a manufacturing process perspective

Problem solving: help customers to solve technical problems in production

Cost control recommendations: help reduce manufacturing costs while maintaining quality

3 Successful Cases: Automotive Parts Processing

We have provided machining services for an automotive parts supplier. We helped the customer by optimising the machining process and strict quality control:

Reduced product defect rate: from 3.2% to less than 0.5%

Productivity improvement: single piece processing time reduced by 18%

Cost savings: annual production cost reduction of approximately $250,000

4 How to choose a professional processing plant?

When choosing a machining service provider, it is recommended to consider the following factors:

Condition of equipment: check the make, model and newness of processing equipment

Technical team: find out about the qualifications and experience of the technicians

Quality certifications: confirm the availability of relevant industry certifications

Reference cases: examine whether there are successful cases in similar industries-6

5 Conclusion

In today's increasingly sophisticated manufacturing industry, it is crucial to choose a professional machining plant. With advanced equipment, a professional technical team and a comprehensive quality management system, we can provide high quality machining services for your projects. Feel free to contact us to discuss your machining needs.

No comments