Innovation drives the future:Heavy Equipment ManufacturingFive Technology Trends

1 Introduction: The Changing Field of Heavy Industry

In the context of the global move towards intelligence and greening, the field of heavy equipment manufacturing is experiencing a profound technological revolution. Traditional mechanical equipment is being deeply integrated with a new generation of information technology, giving rise to more efficient, safer and more environmentally friendly solutions. This article will provide you with an in-depth analysis of the five key technology trends that are currently shaping the future of heavy equipment manufacturing, and help you stay ahead of the industry changes.

2 Analysis of five major technology trends

2.1 Automation and Intelligence

Automation is no longer a new concept, but intelligence gives a new connotation to heavy equipment manufacturing.

Driverless and remote control: In mining, harbours and other scenarios, driverless trucks and remote-controlled excavators have been put into practice, significantly improving operational safety and efficiency-3.

Predictive maintenance: Through on-board sensors and IoT technology, equipment can analyse its own health status in real time and predict potential failures, turning "reactive maintenance" into "proactive maintenance" and minimising downtime-9.![图片[1]-创新驱动未来:重工设备制造的五大技术趋势(未来的重工设备制造将更加聚焦于“人机协同”)-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/09/QQ20250927-182317-800x593.png)

2.2 Digital twins

Digital twinning, which involves building a digital model in virtual space that corresponds exactly to a physical entity, is changing the R&D and O&M model of heavy equipment manufacturing.

Simulation and optimisation can be carried out in the design phase through digital models, reducing the cost and risk of physical testing.

In the operations and maintenance phase, real-time data from physical equipment drives digital models that can be used for troubleshooting, operator training and operational scenario previews.

2.3 Green and Sustainable Development

Increasingly stringent environmental regulations and the global quest for sustainable development are driving a green transition in heavy equipment manufacturing.

New energy power: R&D and application of pure electric and hybrid construction machinery is accelerated to reduce carbon emissions on construction sites-3.

Noise and Dust Control: Advanced noise reduction technology and efficient dust removal systems have become important selling points for new equipment.

Remanufacturing and recycling: Repairing or upgrading old parts through precision machining technology to extend the life cycle of equipment and reduce resource consumption.

2.4 Applications of Additive Manufacturing (3D Printing)

3D printing technology is moving from prototyping to the production of functional parts in heavy equipment manufacturing.

Complex part manufacturing: Complex internal runners or lightweight structures that are difficult to achieve with conventional machining can be moulded in one go-9.

Rapid spare parts supply: For out-of-production equipment or urgently needed spare parts, 3D printing can greatly shorten the delivery cycle and safeguard the customer's production.

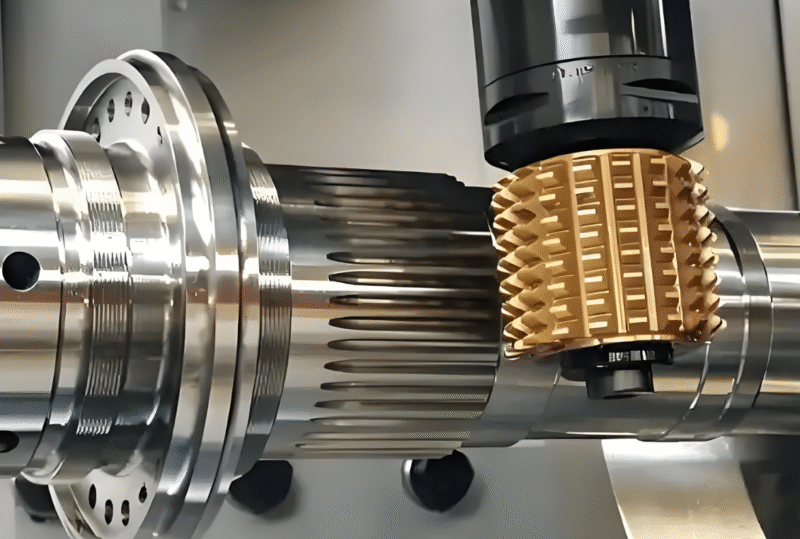

2.5 Modular Design and Flexible Production

In order to meet the diversified and individual needs of the market, modular design has become the trend.

Advantage: By breaking down the equipment into several standard functional modules, it is possible to quickly configure products to meet different customer needs and shorten the design and manufacturing cycle.

Value: This not only improves the market response speed of machinery and equipment manufacturers, but also brings more flexible equipment selection and upgrade solutions to customers.![图片[2]-创新驱动未来:重工设备制造的五大技术趋势(未来的重工设备制造将更加聚焦于“人机协同”)-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/06/QQ20250625-204151-800x406.png)

3 Success Stories: The Power of Intelligence

We supplied an intelligent mine crushing plant to a large cement group.

Challenge: The customer wanted to reduce the number of personnel on site and increase overall equipment utilisation.

Solution: We equipped it with a comprehensive sensor network and 5G communication module, enabling remote status monitoring, fault diagnosis and unmanned operation of the equipment. Meanwhile, based on operational big data, we optimised the crusher's operating parameters.

Achievements: The customer has realised the "black light factory" type of mining operation, the manpower cost has decreased by more than 60%, and the comprehensive efficiency of the equipment has increased by 15%, which fully demonstrates the great potential of the intelligent heavy industry equipment manufacturing.

4 Future prospects

prospectiveHeavy Equipment ManufacturingThere will be a greater focus on "human-machine collaboration". Artificial intelligence technology will enable equipment to have stronger environmental awareness and autonomous decision-making capabilities, while operators will play more of a managerial and decision-making role. At the same time, data-based services will become the new core competitiveness of manufacturing enterprises.

5 Conclusion

Technological innovation is the fundamental driving force that drives the heavy equipment manufacturing industry forward. Embracing automation, digitalisation and green technology is not only a need to enhance product competitiveness, but also an inevitable choice to respond to the development of the times. We are always committed to integrating cutting-edge technology into our machinery and equipment manufacturing practices to create future-oriented superior value for our customers.

1 Introduction: The Changing Field of Heavy Industry

In the context of the global move towards intelligence and greening, the field of heavy equipment manufacturing is experiencing a profound technological revolution. Traditional mechanical equipment is being deeply integrated with a new generation of information technology, giving rise to more efficient, safer and more environmentally friendly solutions. This article will provide you with an in-depth analysis of the five key technology trends that are currently shaping the future of heavy equipment manufacturing, and help you stay ahead of the industry changes.

2 Analysis of five major technology trends

2.1 Automation and Intelligence

Automation is no longer a new concept, but intelligence gives a new connotation to heavy equipment manufacturing.

Driverless and remote control: In mining, harbours and other scenarios, driverless trucks and remote-controlled excavators have been put into practice, significantly improving operational safety and efficiency-3.

Predictive maintenance: Through on-board sensors and IoT technology, equipment can analyse its own health status in real time and predict potential failures, turning "reactive maintenance" into "proactive maintenance" and minimising downtime-9.

2.2 Digital twins

Digital twinning, which involves building a digital model in virtual space that corresponds exactly to a physical entity, is changing the R&D and O&M model of heavy equipment manufacturing.

Simulation and optimisation can be carried out in the design phase through digital models, reducing the cost and risk of physical testing.

In the operations and maintenance phase, real-time data from physical equipment drives digital models that can be used for troubleshooting, operator training and operational scenario previews.

2.3 Green and Sustainable Development

Increasingly stringent environmental regulations and the global quest for sustainable development are driving a green transition in heavy equipment manufacturing.

New energy power: R&D and application of pure electric and hybrid construction machinery is accelerated to reduce carbon emissions on construction sites-3.

Noise and Dust Control: Advanced noise reduction technology and efficient dust removal systems have become important selling points for new equipment.

Remanufacturing and recycling: Repairing or upgrading old parts through precision machining technology to extend the life cycle of equipment and reduce resource consumption.

2.4 Applications of Additive Manufacturing (3D Printing)

3D printing technology is moving from prototyping to the production of functional parts in heavy equipment manufacturing.

Complex part manufacturing: Complex internal runners or lightweight structures that are difficult to achieve with conventional machining can be moulded in one go-9.

Rapid spare parts supply: For out-of-production equipment or urgently needed spare parts, 3D printing can greatly shorten the delivery cycle and safeguard the customer's production.

2.5 Modular Design and Flexible Production

In order to meet the diversified and individual needs of the market, modular design has become the trend.

Advantage: By breaking down the equipment into several standard functional modules, it is possible to quickly configure products to meet different customer needs and shorten the design and manufacturing cycle.

Value: This not only improves the market response speed of machinery and equipment manufacturers, but also brings more flexible equipment selection and upgrade solutions to customers.

3 Success Stories: The Power of Intelligence

We supplied an intelligent mine crushing plant to a large cement group.

Challenge: The customer wanted to reduce the number of personnel on site and increase overall equipment utilisation.

Solution: We equipped it with a comprehensive sensor network and 5G communication module, enabling remote status monitoring, fault diagnosis and unmanned operation of the equipment. Meanwhile, based on operational big data, we optimised the crusher's operating parameters.

Achievements: The customer has realised the "black light factory" type of mining operation, the manpower cost has decreased by more than 60%, and the comprehensive efficiency of the equipment has increased by 15%, which fully demonstrates the great potential of the intelligent heavy industry equipment manufacturing.

4 Future prospects

The future of heavy equipment manufacturing will focus more on "human-machine collaboration". Artificial intelligence technology will enable equipment to have stronger environmental awareness and autonomous decision-making capabilities, while operators will play more of a manager and decision-maker role. At the same time, data-based services will become the new core competitiveness of manufacturing enterprises.

5 Conclusion

Technological innovation is the fundamental driving force that drives the heavy equipment manufacturing industry forward. Embracing automation, digitalisation and green technology is not only a need to enhance product competitiveness, but also an inevitable choice to respond to the development of the times. We are always committed to integrating cutting-edge technology into our machinery and equipment manufacturing practices to create future-oriented superior value for our customers.

No comments