Precision machiningand finishing: the cornerstone of modern manufacturing

I. Introduction: how precision is reshaping manufacturing

In today's manufacturing world, precision machining and finishing are no longer optional options, but rather core aspects that determine the performance, reliability and longevity of products. From the highly efficient engines of automobiles to the complex components of spacecraft, the pursuit of precision is behind the products that underpin modern technology. This article takes a closer look at these key technologies and reveals how they have become an indispensable cornerstone of modern manufacturing.

II. Core concepts: from "precision" to "ultra-precision"

What is precision machining?

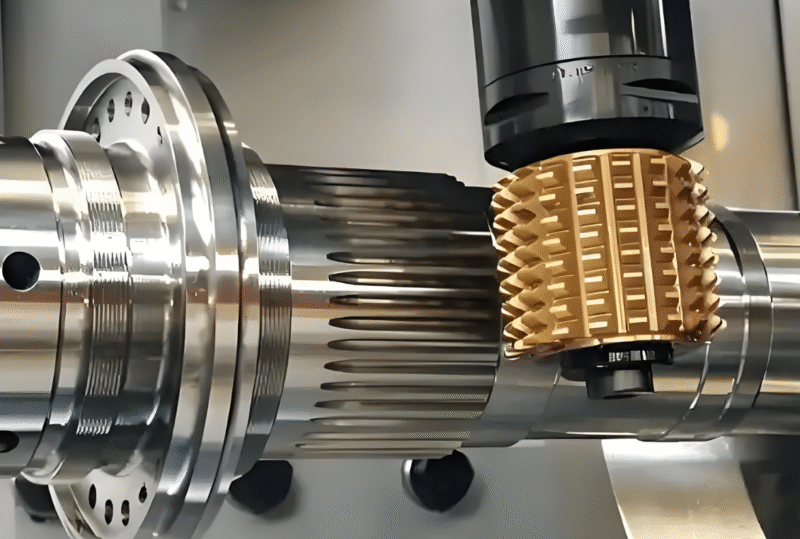

Precision machining is a series of processes to achieve very high machining accuracy and surface quality as the goal of the general term-1, which covers a variety of methods of precision cutting (such as precision turning, wide-edge precision planing) and high-finish high-precision grinding, etc.-1. Its machining accuracy is usually between 10 ~ 0.1 micron (μm), the surface roughness Ra value can be controlled in the 0.1 μm or less-1.

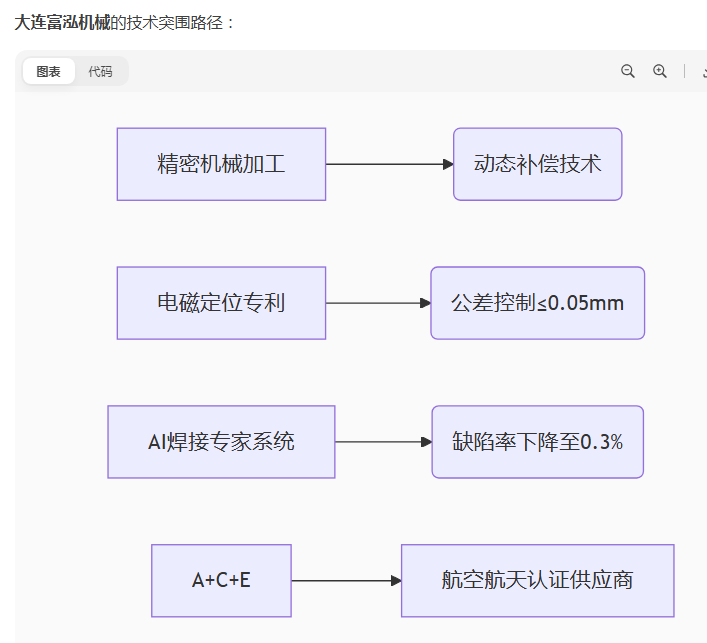

The complete process of finishing![图片[1]-精密机械加工与精加工:现代制造业的基石(精密机械加工与精加工:现代制造业的基石,为确保最终产品在激烈市场竞争中的可靠性与卓越性能奠定了坚实基础)-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/10/QQ20251002-202038-800x562.png)

Finishing is not a one-step operation, but a systematic process. It usually includes:

Roughing: The goal is to quickly remove most of the machining allowance in preparation for subsequent processes-5.

Semi-finishing: This is carried out after roughing and is intended to leave a uniform and moderate allowance (usually 0.1-0.02 mm) for final finishing and to reduce the distortion of the workpiece due to the heat of cutting-5.

Finishing: the final process, the goal is to make the parts to achieve the dimensional accuracy and surface finish required by the design drawings -5.

III. The key to achieving high precision: unification of technology, equipment and environment

Achieving stable and efficient precision machining relies on the synergy of several elements:

Superior process technology: Precision cutting, for example, relies on high-precision machine tools and finely sharpened cutting tools to significantly improve machining accuracy and surface quality through very small cutting volumes-1, while high-finish, high-precision grinding uses finely dressed grinding wheels that utilise micro-cutting edges and friction-polishing to achieve high-precision and low-roughness surfaces-1.

Stable and specialised equipment: Precision machining usually needs to be carried out on specialised machines in order to avoid rough machining equipment affecting accuracy due to different loads-5. At the same time, ultra-fine machining equipment such as CNC machining centres, precision grinding machines and CNC lathes have a unique advantage in the machining of small-lot, high-precision parts due to their own high-precision and high-automation characteristics-7.

Controlled support environment: High-precision machining is extremely sensitive to the environment, and temperature control, cleanliness and vibration protection are elements that must be taken into account-3-5.

IV. Conclusion: irreplaceable values

Precision machining and finishing are the cornerstones of modern manufacturing-1 and provide a solid foundation for ensuring the reliability and superior performance of end products in a competitive marketplace. The mastery and application of these technologies is of irreplaceable strategic value to any company committed to manufacturing high-quality products.

Call-to-Action ★

Are you looking for a high-precision, high-reliability machining solution for your project? Take a look at our technical competence brochure today, or contact our team of experts for tailor-made professional advice.

No comments