In-depth knowledge of modernMetallurgical equipmentKey technological breakthroughs, including electric arc furnaces, continuous casting machines and automated control systems, on how to improve the efficiency, quality and environmental performance of metal smelting.

Text: The progress of the metallurgical industry relies heavily on the continuous innovation of metallurgical equipment at its core. From ore to high-purity metal materials, every step of the way is supported by sophisticated, efficient and reliable equipment. In this article, we take you on a journey through the current technological frontiers in the field of metallurgical equipment.![图片[1]-冶金设备技术前沿:从高效熔炼到智能化控制的全面革新-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/11/QQ20251002-201616.png)

1. High-efficiency melting equipment: the heart of the metallurgical process Melting is the core of metallurgy, and the performance of its equipment directly determines the level of production efficiency and energy consumption. Ultra-high-power electric arc furnace: In modern steel production, electric arc furnaces are becoming increasingly important due to their flexibility and environmental advantages. The new generation of ultra-high-power electric arc furnace significantly shortens the smelting cycle, reduces the unit power consumption, and is the core equipment for short-process steelmaking. Flash Melting Furnace: In the smelting of non-ferrous metals (e.g. copper, nickel), the flash melting technology has the advantages of high strength, low energy consumption and high sulphur recovery rate, representing the development direction of green smelting.

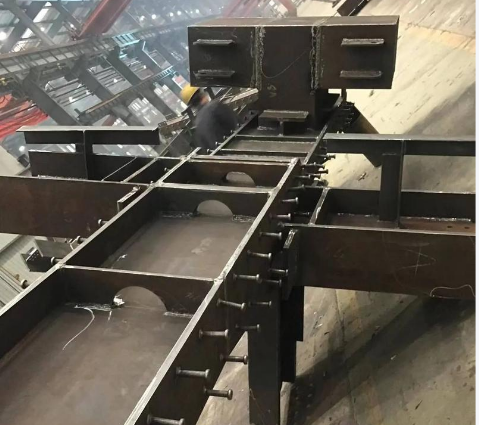

2. Continuous casting equipment: improve the quality and yield rate Continuous casting machine has basically replaced the mould casting process, which solidifies the steel directly into the desired shape of the billet. Thin Slab Continuous Casting and Rolling Technology: Continuous casting and rolling processes are seamlessly connected, which greatly saves energy, shortens the production process, and is the key to achieving high efficiency and low cost production. Intelligent mould: The mould is the “heart” of the continuous casting machine, through the built-in sensors and advanced control system, it can real-time monitor the liquid level of steel, cooling intensity, to ensure that the internal quality of billet casting is uniform and stable.![图片[2]-冶金设备技术前沿:从高效熔炼到智能化控制的全面革新-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/11/QQ20251002-201517.png)

3. Automation and intelligent control system Modern metallurgical workshop is developing in the direction of “black light factory”, behind which is a powerful control system. Process control system: real-time acquisition and optimal control of thousands of parameters such as temperature, pressure, composition, etc. to ensure that the production process is in the best state. Predictive maintenance system: Through the analysis of equipment vibration, temperature and other data, early warning of potential failures, scheduled maintenance, to avoid unplanned downtime brought about by huge losses. 4. Environmental protection and resource equipment Environmental protection pressure has driven the rapid development of related equipment, such as: sintering flue gas desulphurisation and denitrification equipment: effective removal of sulphur compounds and nitrogen oxides in the flue gas. Metallurgical slag treatment and resource utilisation equipment: process solid wastes such as blast furnace slag and steel slag into raw materials for building materials, so as to turn waste into treasure.

Summary: HyundaiMetallurgical equipmentIt is developing rapidly in the direction of large-scale, high-efficiency, intelligent and green. Investing in advanced metallurgical equipment is not only the key to enhance the competitiveness of enterprises, but also the fundamental guarantee for the sustainable development of the metallurgical industry.

No comments