directly facingmanufacturingThis article explores how clean technologies and policy guidance can help heavy industry move towards a sustainable future. This paper explores how clean technologies, circular models and policy guidance can help heavy industry move towards a sustainable future.

Text: As the world's attention is focused on climate change and environmental protection, heavy industry, as a major consumer of energy and emissions, is undoubtedly facing unprecedented pressure. However, challenges and opportunities exist side by side, and this green revolution is also giving rise to unprecedented innovation and growth in the heavy industry sector.

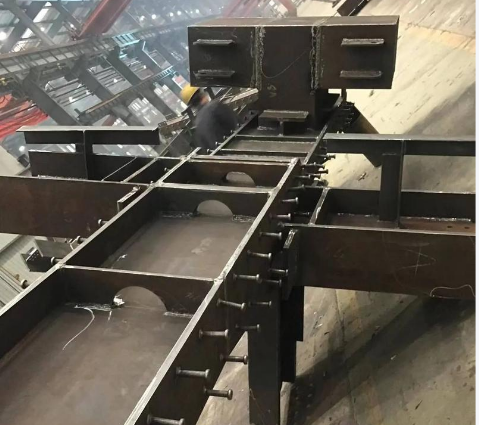

1. Core challenges Large carbon footprint: Production processes in industries such as steel, cement and chemicals involve the combustion of large amounts of fossil fuels and chemical reactions, which are one of the main sources of CO2 emissions. Resource-intensive: Extremely dependent on natural resources such as ore, coal and water. Waste and Pollution Control: The treatment of waste slag, waste water and waste gas is always a difficult problem for the industry.![图片[1]-可持续发展下的重工业:挑战、机遇与创新解决方案-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/11/QQ20251002-201008.png)

2. Shifting to a circular economy model The linear economy model of “take - make - waste” is no longer sustainable. Heavy industry is actively exploring circular economy pathways: Material innovation: Research and development for the use of recyclable or bio-based materials. Industrial symbiosis: Using by-products from one factory (e.g. waste heat, blast furnace gas) as raw materials or energy for another factory, forming an eco-industrial park with shared resources. Product Life Cycle Management: Consideration of disassembly, recyclability and remanufacturing potential from the design stage.

3. Breakthrough applications of clean technologies Hydrogen steelmaking: Using hydrogen instead of coal as a reductant, with water as a by-product, can fundamentally eliminate carbon emissions from the steelmaking process, and is the most promising disruptive technology available. Carbon Capture, Utilisation and Storage (CCUS): As mentioned earlier, CCUS technology is a viable option for deep decarbonisation of existing facilities. Electrification: Substitution of fossil fuels with electricity, accompanied by the use of renewable energy sources, where feasible.

4. Driven by both policies and markets Carbon tax policies, green financial support and consumer preference for low-carbon products, such as “green steel”, in countries around the globe are creating a strong external impetus for the green transformation of heavy industry. Summary: The impact of sustainable development onmanufacturingIn terms of social responsibility, it has gone from being an option to being a must. It's not just about social responsibility, it's at the heart of a strategy for business survival and competitiveness. Those who are the first to adopt and invest in innovative green solutions will have an absolute advantage in the marketplace of the future.

No comments