Please note that in view of the restructuring of our business, we will not be accepting individually commissioned tests for the time being, and we hope that you will understand that (individually commissioned tests of universities, research institutes, etc. are excluded from this list).

Because of the length, CMA, CNAS, ISO certificates, and items and samples that are not listed, you need to consult the online engineers.

Test items

This is a static pressure holding test: the maximum working pressure is tested to verify the design pressure, the time of pressure holding, the value of pressure decay, the permissible leakage rate, the pressure versus time curve to assess the stability of the pressure holding, the number of pressure cycles, the determination of residual pressure, the range of pressure fluctuations, and the assessment of the overall system tightness.

The airtightness leakage detection, quantitative leakage rate measurement, leakage point localisation, bubble detection method and pressure change method, calculation of cumulative leakage, tracer gas (like helium) leakage detection, vacuum mask method and suction lance method, leakage rate calibration, background leakage correction, micro-leakage detection, and leakage assessment of sealing surfaces to unfold the full stop.

3. Hydraulic strength test, the test pressure, which is usually a multiple of the design pressure, with the requirement of the rate of pressure increase, and the time limit for pressure stabilisation, visual inspection, the need to monitor the deformation of the structure, the need to check the area of stress concentration, the need to pay attention to the temperature of the test medium, with the provision of the rate of pressure relief, the need to carry out a cosmetic inspection after the test, and the necessity of checking the leakage of weld seams, and also flange joints. Inspection.

4. Blast pressure testing is performed to test ultimate pressure capacity, to obtain blast pressure values, to analyse failure modes (ductile or brittle fracture), to observe the morphology of the blast opening, to plot pressure-volume change curves, to carry out verification of the safety factor, to assess plastic deformation of the material, to measure strains, and to carry out acoustic emission monitoring.

5. Sealing element performance tests are carried out to test gasket compression resilience characteristics, test seal specific pressure, test gasket stress relaxation, test creep behaviour, test media compatibility, test the effects of temperature cycling, test the hardness of the sealing material, test the rate of permanent deformation in compression, test the sealing performance of the stuffing box, assess the O-Ring extruded gap, and assess sealing force of the lip seal.

6. Evaluate the flange connection system, present the distribution of bolt preload, analyse the phenomenon of flange deflection and tension, consider the gasket compression stress value, carry out hot state relaxation analysis, explore the bolt load decay law, analyse the level of flange sealing surface flatness, examine the sealing line contact condition, implement high temperature and high pressure working condition simulation operation, and study the sealing performance performance under cyclic loading.

7. Valves are subjected to high-pressure sealing tests, which include seat sealing, including upstream sealing and downstream sealing, as well as assessing the sealing of the stem packing, conducting opening and closing torque tests, evaluating micro-leakage ratings, detecting sealing performance under high pressure differentials, carrying out life-cycle tests, comparing soft seals with metal seals, and simulating fire-safety tests.

8. As far as welded joints are concerned, there are special tests for sealing and strength, including weld leakage channel testing, heat-affected zone sealing testing, correlation analysis between the results of non-destructive testing and sealing, analyses of the effects of residual welding stress on sealing, testing of sealing performance of fillet welds, testing of sealing of the root of butt welds, and testing of leakage between layers of multi-layer wrapped or wrapped structures, and so on.

9. Pressure cycling and fatigue sealing tests, which include the number of pressure transitions, as well as the pressure amplitude and cycling frequency, the decay curve of sealing performance, the monitoring of leakage development, the fatigue life of the sealing element, the evaluation of micromotor wear of the flange connection, and the relaxation behaviour under cyclic loading.

10. Simulation testing of extreme working conditions: sealing tests in high-temperature and high-pressure composite environments, testing the sealing performance at low temperatures, exploring the impact of thermal shock on the seal, testing the durability of the seal in corrosive media conditions, examining the stability of the seal in vibration environments, analysing the differences between high-pressure gases and high-pressure liquids in terms of sealing, and carrying out rapid pressure impact (water hammer) tests.

The correlation between NDT and sealing will be analysed by using ultrasonic test results, radiographic test results, penetrant test results and magnetic particle test results to predict potential leakage risks, carry out sealing safety evaluations for the dimensions of the defects, for the location of the defects, for the nature of the defects, and to determine the permissible defect tolerances based on the combination of the above.

Twelve, the overall system sealing function test, in that simulated or close to the actual working conditions, for the entire pressure system, including vessels, pipelines, valves, instrumentation joints, etc., to develop into an integrated sealing performance test to assess the system in the linkage state of the leakage level.

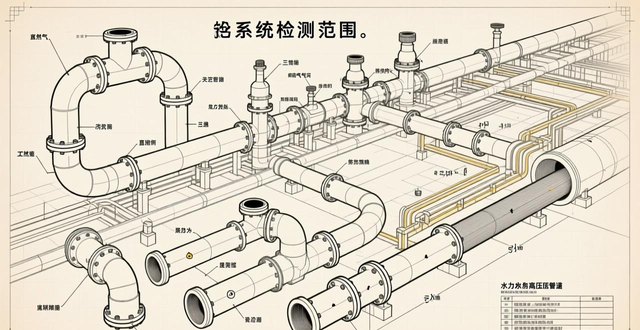

Detection range

1. Belonging to the pressure vessel category are, reaction kettles, heat exchangers, gas storage tanks, oil storage tanks, separators, buffer tanks, autoclaves, synthetic towers, sterilisation cabinets, etc., which are fixed and mobile containers. The sealing involves all the pressure-bearing boundary parts, including the shell, head, open receiver, manholes, handholes, and so on.

![图片[1]-高压密封测试机构,高压密封检测报告-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768731142430_0.png)

2. Long-distance pipeline system and industrial pipeline system: there are oil and gas pipelines, chemical process pipelines, city gas pipeline network, thermal pipelines, and high-pressure pipelines for hydroelectric power generation. The inspection scope covers straight pipe sections, elbows, tees, pipe fittings such as reducers, welded joints and flange joints along the whole line.

3. Valve products include gate valves, globe valves, ball valves, butterfly valves, plug valves, check valves, safety valves, regulating valves and so on. Focus on testing the sealing performance between the valve seat and the closing member, also focus on testing the sealing performance between the valve stem and the stuffing box, and focus on testing the sealing performance of the valve body connection.

4. Pumps and compressors involved in the fluid end of the parts, centrifugal pumps, reciprocating pumps, piston pumps, including pump casing, sealing chamber, inlet and outlet flanges; compressor components are cylinders, cylinder heads, stuffing box, intercooler, piping system is located in the high-pressure parts of the seal.

5. Hydraulic and pneumatic systems in the aerospace sector, including hydraulic systems for aircraft landing gear, as well as fuel systems, in addition to engine and hydraulic control systems, such as propellant delivery systems for spacecraft, and high-pressure seals for hatch seals, joint seals for spacesuits, etc., as well as joints.

6. High-pressure systems in the automotive industry include fuel injection systems, including common rail pipes and injectors, braking systems, air-conditioning systems, hydrogen fuel cell storage cylinders and lines for new energy vehicles, and coolant lines for battery packs.

7. Key components of energy equipment, including boiler drums, as well as header tanks, and superheater couplings; nuclear power plant reactor pressure vessels, steam generators, and main pump seals; hydraulic turbine casings and valves; and hydraulic pitch systems for wind power generation.

8. Equipment with high-pressure capabilities for medical use includes hyperbaric chambers, steam sterilizers, gas piping systems for medical use, including oxygen and nitrous oxide, systems for the delivery of water in haemodialysis machines, and channels for the delivery of gas and water in integrated dental treatment tables.

9. Scientific experimental installations, including various types of high-pressure reaction equipment, supercritical fluid extraction equipment, high-pressure synthesis equipment for materials, vacuum and high-pressure systems for particle accelerators, and pressure chambers for deep-sea simulation.

For 10. sealing elements and materials, separate products such as toothed gaskets, octagonal gaskets, elliptical gaskets for metallic gaskets, rubber, PTFE, graphite for non-metallic gaskets, wound gaskets for semi-metallic gaskets, O-rings, sealants and packings, etc., are subject to factory performance verification.

11. Special equipment and connection forms include quick release couplings, connections applied by clamps, threaded connections, lens gasket seals, tube fittings, vacuum and high pressure feedthroughs, rotary joints, i.e. the type of mechanical seals, and so on.

Periodic inspection of all types of high-pressure equipment that have been put into use, for piping systems, at regular intervals or after a failure, to carry out sealing performance retests, but also to carry out a safety assessment, which is part of the periodic inspection of equipment in service.

Testing equipment

![图片[2]-高压密封测试机构,高压密封检测报告-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768731142430_1.webp)

Pressure cooker tightness tester, it integrates the pressure control function, and data acquisition function and leakage calculation function, it adopts the pressure drop method or differential pressure method, its accuracy is very high, it can automatically determine the leakage rate, it is applicable to the factory test of such products as valves, but also applicable to the factory test of such products as small containers.

2. Helium mass spectrometry leak detector, which uses helium as a tracer gas, has a very high detection sensitivity, which can reach the order of ten minus ten times the cubic metre per second, and it is also equipped with suction lance, equipped with a vacuum hood, equipped with a helium-filled hood, and other probes, which are used in the localisation of the detection of small leaks, and in the quantitative detection of small leaks.

A pumping station for hydraulic testing, which includes a special high-pressure pump, a control system, a pressure gauge, safety valves and piping, etc., capable of supplying a stable, high-pressure liquid pressure source, is used to carry out hydraulic strength tests and bursting tests in a wide range of pressure areas.

4. Gas booster system, which uses gas-driven mode, or electric mode, the compressed air to tens of megapascals, or even hundreds of megapascals, it will also be nitrogen to tens of megapascals, or even hundreds of megapascals, which is used to carry out high-pressure gas sealing test, but also used to carry out the strength of the pneumatic test, which compared with the hydraulic pressure is safer. However, it requires more equipment.

Digital torque spanners for precise control of bolt preload in flanged joints and bolt elongation gauges to ensure a uniform and appropriate sealing ratio for gaskets, the latter calculating the axial force indirectly by measuring the change in length of the bolt with greater accuracy.

![图片[3]-高压密封测试机构,高压密封检测报告-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768731142430_2.png)

Highly accurate pressure transducers that measure pressure changes during the test process, with high resolution, high stability, and fast response characteristics, and data loggers that continuously record multi-channel signals such as pressure and temperature over a long period of time.

7. Tanks and visualisation devices for bubble leakage detection: these are specifically designed to carry out immersion bubble tests. It is a transparent, pressurised tank or a device with an observation window, which allows pressure to be exerted on the workpiece to be measured, which is then immersed in the water, with the aid of observing the position of the bubbles and the frequency of their appearance, and thus determining the location of the leaks in terms of their nature.

Valve test bench, is specially used for valve sealing performance testing equipment, it can simulate the valve upstream sealing, downstream sealing and stem sealing and other working conditions, will automatically carry out the pressurisation, holding pressure, testing and recording, its high degree of integration.

The chamber, called the High Temperature High Pressure Environmental Simulation Chamber, creates a complex environment of high temperatures, up to hundreds of degrees, and high pressures, either in the form of gases or liquids, which can be precisely controlled. The chamber is used to test the long-term performance of seals and connecting structures under extreme conditions. The chamber is used to test the long-term performance of seals and connecting structures under extreme operating conditions.

10. Acoustic Emission Detection (AED) systems: During the pressure test process, acoustic emission signals generated by defect expansion, leakage or friction within the material are monitored in real time and can be used to locate active leakage sources or to predict structural failures.

Infrared thermography can be used to detect leaks in high pressure gases. When a leak occurs in a high pressure gas, the local temperature becomes abnormal due to the throttling effect, and infrared thermography can be used to locate the leak area in a wide range of areas and at high speeds without contact.

12. In-pipe detectors and smart spheres: For long-distance buried pipelines or overhead pipelines, smart in-pipe detectors with pressure sensors and smart in-pipe detectors with acoustic sensors can be used to detect and locate leaks on-line during the operation of the pipeline.

Relevant test development prospects and outlook

Intelligent, online and high-precision direction is the direction of development of high-pressure seal detection technology. The convergence of the Internet of Things and sensor technology will promote the popularity of real-time online leakage monitoring systems to achieve predictive maintenance. Artificial intelligence algorithms will be used to analyse complex inspection data to improve the accuracy of leak location and risk assessment. Miniaturised and highly sensitive sensors will make early detection of micro-leaks possible. At the same time, for new energy, deep space and deep sea exploration and other emerging areas of extreme working conditions of the seal test methods and standards, urgently need to be established and improved, which will be the key direction of the future direction of technology research.

Institute of Testing Technology

![图片[4]-高压密封测试机构,高压密封检测报告-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768731142430_3.webp)

Reporting: Third party test reports (electronic/paper) can be issued.

Testing period: 7~15 working days, can be expedited.

Qualification: Its laboratory can issue CMA/CNAS/ISO qualification reports.

Standard Test: Strictly according to the national standard/line standard/enterprise standard/international standard test.

Non-standard testing: support for customised test solutions.

After-sale: Lifetime report availability, 1v1 engineer service.

No comments