The present invention relates to the processing and welding of outfittings, specifically, a welding device for marine outfittings, and a method of welding the device.

Background technology:

1, marine outfitting is a situation, that is, after the completion of the construction of the main structure of the hull of the ship, after the launch of the ship to carry out the installation of mechanical, electrical and electronic equipment, ship outfitting is covered by the removal of the hull of the ship and the ship's power plant on board of all things, and ship outfitting is used for the main structure of the ship as well as the equipment for the connection of the installation of connecting parts.

2. At present, outfittings are completed by welding, and when some cylindrical outfits are welded to other workpieces, the lack of fixing devices results in poor welding, and most of them are welded manually by personnel, which is not only labour-intensive, but also has an impact on work efficiency; although there are some outfits on the market that can be mechanically fastened, the outfittings are fixed differently due to the different sizes of outfits and welding methods. Although there are a number of mechanical fixing methods available on the market, these are not as effective as they could be due to the different sizes of outlets and the different welding methods used to fix them, and the single fixing method used is ineffective in fixing different outlets, especially taller outlets.

Technical realisation ideas

1. (i) Technical programmes

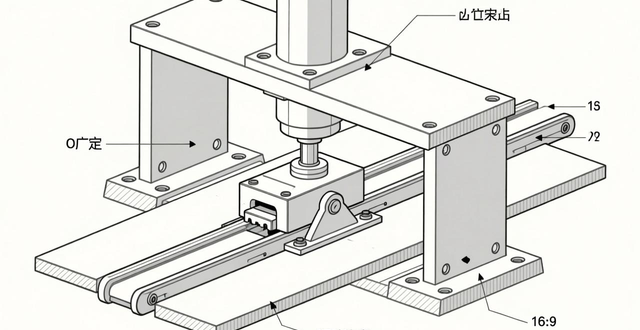

First, in order to solve such a technical problem, the present invention gives the following technical solution. Second, there is a welding device for marine outfittings. Third, the device comprises an abutment. Fourth, there is a fixed-point clamping mechanism positioned above the abutment. Fifth, the fixed-point clamping mechanism comprises an adjusting frame and a support sleeve. Sixth, the support sleeve comprises a plurality of support plates capable of rotating with each other. Seventh, the adjusting frame is capable of moving one end of the support sleeve plate. Eighth, the other end of the support sleeve plate will slide relative to the surface of the abutment. Ninth, the support plate is provided with a clamping tooling. Tenth, the position of the clamping tooling is adjusted by rotation of the support plate. Eleventh, so that the clamping tooling can clamp different workpieces.

3, preferably, the central position above the abutment is provided with an anti-slip plate, between the anti-slip plate and the abutment is rotating, the anti-slip plate has fixed bolts at both ends, with the help of the fixed bolts through the anti-slip plate and with the abutment to achieve the surface of the locking, the anti-slip plate is curved groove, the anti-slip plate is set inside the curved groove anti-slip stripes.

4, Preferably, said adjusting frame comprises a support frame which is firmly set on the upper surface of said abutment, said support frame being provided with a number of sets of moving slides, said moving slides containing guide rods and said moving slides containing sliding blocks, said sliding blocks being in a sliding fit condition with said guide rods, and said moving slides being provided with a driving member on the external side of said moving slides, which is used to drive said sliding blocks.

5, preferably, said driving member comprises a driving screw, both ends of said driving screw are set in a rotating manner with said support frame, a threaded block is set on top of said driving screw, said driving screw induces a movement of said threaded block, and a linkage is set on one side of said threaded block; said linkage comprises a linkage block, said linkage block is firmly connected with said threaded block, and a linkage card is set on one side of said linkage block, said linkage card is capable of connecting any one of said sliding blocks to said linkage block, and said linkage card is capable of connecting any one of said sliding blocks to said linkage block. said linkage is provided with a linkage block, said linkage block being capable of connecting any one of said sliding blocks to said linkage block.

6 、Preferably, said adjusting frame additionally contains a lifting frame, said lifting frame is between two opposite said supporting frame, said lifting frame contains a number of lifting plates, each said lifting plate is connected to said sliding block at both ends respectively, the middle of each said lifting plate is provided with a fixed half-arc hole, said fixed half-arc hole is provided with a sliding half-arc hole, said sliding half-arc hole is provided with respect to said lifting plate to be able to play the role of limiting, said fixed half-arc hole will form a complete fixed hole when combined with said sliding half-arc hole. The sliding half-arc holes can play a limiting role in relation to the lifting plate, and the fixed half-arc holes and the sliding half-arc holes will form a complete fixing hole when they are combined.

7, preferably, the said support plate also contains a locking assembly, the locking assembly is fixed at the bottom position of the support plate there, the locking assembly contains a locking slot, the locking slot is provided with a locking slide, the locking slide relative to the locking slot can be achieved by fixing the locking slide, the locking slide is provided with a mounting plate above, the bottom of the support plate and the mounting plate is rotationally connected, the support plate is three, each two neighbouring support plates are rotationally set with each other, and the support plate is rotationally set with each other. There are three support plates in total, and each two neighbouring support plates are rotated to each other.

![图片[1]-一种船用舾装件焊接装置及其焊接方法与流程-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768789483510_0.png)

Preferably, said clamping tooling comprises a movable tooling and a fixed tooling, said movable tooling being provided on top of said support plate located in the middle, said fixed tooling being fixed on top of said support plate located in the top, said fixed tooling being connected to said lifting plate by means of said fixing holes.

Preferably, said movable workpiece contains a spherical movable member, a spherical groove is provided on top of said support plate in the middle, said spherical movable member is connected to said spherical groove, said spherical movable member is provided with a mounting tube through the centre, said mounting tube is provided with a drive rod in the inner part of the mounting tube, a drive part is provided at one end of said drive rod, said drive part drives said drive rod to rotate, said drive rod is provided with a propelling screw at the bottom of said drive rod, said propelling screw is threaded with a propelling column, said said propelling screw is threaded to a propelling column, said propelling column is provided with guiding blocks on both sides, said mounting tube is provided with guiding grooves on both sides, said propelling spring is provided at the end of said propelling column, said propelling column is provided with a first propelling cylinder on the outside of said propelling spring, said first propelling cylinder is provided with a sliding fit to said propelling column, said first propelling cylinder is connected internally to the end of said propelling spring.

10, more preferably, said fixing workpiece contains a fixing column which is fixedly connected to said support plate at said top position, a fixing spring is provided at the end of said fixing column, and a second propelling cylinder is provided on the outside of said fixing column and said fixing spring.

11. (ii) Beneficial effects

When the present invention is compared with the prior art on a case-by-case basis, the present invention provides a welding device for marine outfittings which has the following beneficial effects:

Firstly, the marine outfitting welding device is supported on the underside of the welding outfittings by means of a skid plate, the fixing bolts on both sides of the skid plate are loosened before the welding outfittings are clamped and fixed, and the welding outfittings are lifted above the abutment by means of a hoist so that the skid plate receives the welding outfittings, and then the welding outfittings are pushed and the welding outfittings are rotated on the underside of the skid plate and adjusted to a convenient welding position, wherein the skid plate can be a wider curved groove for different sizes of welding outfits, and here it is said that the skid plate is fixed. The welding outfittings are then adjusted to a convenient welding position by pushing on the bottom of the welding outfittings, and then the fixing bolts are tightened so that the skid plate is in a fixed state; wherein the skid plate may be a wider curved groove for welding outfittings of different sizes, as hereinafter referred to in the device described in 13, 1.

This marine outfitting welding unit consists of a movable unit that secures the centre of the outfitting part and a fixed unit that, together with an adjustable frame, secures the upper part of the outfitting part and adjusts the degree and manner of fixation of the entire clamping unit. Once the movable tooling has been pressed against the centre of the outfitting, the fixed tooling is mounted on a lifting plate, with different fixing methods depending on the height of the outfitting. Where outfittings are low or welded top and bottom, a combination of movable and fixed fittings are used to secure the top and bottom of the outfittings. The fixing is carried out by mounting the fixing tooling on the appropriate lifting plate, using the adjusting bracket to hold the fixing tooling diagonally downwards against the top end of the outfitting part, then contracting the movable tooling against the bottom end of the outfitting part, and then advancing the movable tooling so that it applies pressure to the outfitting part. At this point, as both the uppermost and lowermost support plates are in a fixed position, the movable unit on both sides, when pushed in, secures the bottom of the outfitting piece.

The outfittings are welded by means of movable fittings which are fixed individually to the outfittings when they are high up and welded in two parts, the movable fittings are fixed against the outfittings on both sides and then pushed forward by the movable fittings so that the movable fittings are pressed towards the outfittings, when the uppermost support plate is in a movable state the pressure on the outfittings is lower on both sides. The outfittings are pushed by the movable tooling and the pressure on the outfittings is low. The fixed tooling is then fitted to the lifting plate and the plate is raised by the adjusting bracket. The lifting plate is raised by the fixed tooling to raise the uppermost support plate, the bottom of which is moved towards the outfittings, which causes the top of the middle support plate to rise and move closer to the outfittings, and the movable tooling is then further pressed against the outfittings. The mobile unit then exerts further pressure on the outfitting component, providing a more stable hold on the outfitting component.

16. 4. The marine outfitting welding device is provided with a support frame on which there are several sets of travelling slots arranged from inside to outside, so that for different widths of welded outfittings, the corresponding travelling slots and sliding blocks are used, together with lifting frames to fix the welded outfittings; when the drive screw is rotated, it will drive the threaded block with its threads to move up and down; when welding wider and thicker welded outfits, the sliding blocks on the outer side and the lifting plate with the clamping fittings are used to fix the outfits. When welding wider and thicker outfits, the outboard sliding block and lifting plate are used to secure the outfittings in conjunction with the clamping fixtures. By moving the linkage block, the required sliding block is clamped to the linkage block, then the drive screw rotates to move the threaded block, which drives the fixed linkage, and the linkage block in the linkage drives the sliding block; the sliding block moves to drive the lifting plate in between the sliding block. The welding outfittings are fixed in conjunction with the clamping fixtures, wherein the remaining lifting plate, which is not involved in the work, is at the top of the support frame during welding so as not to interfere with the welding.

Technical characteristics:

There exists a welding device for marine outfittings comprising an abutment (1) and a fixed-point clamping mechanism above said abutment (1), having the following characteristics: the fixed-point clamping mechanism comprises an adjusting bracket (2), a support plate (3) comprising a plurality of support plates (31) capable of rotating in relation to each other, the adjusting bracket (2) having the ability to move one end of said support plate (3); the other end of said support plate (3) being moved in relation to said abutment (1); the other end of said support plate (3) having the capability of moving the other end of said support plate (3); and the other end of said support plate (3) having the capability to be moved in relation to said abutment (1). ) having the ability to move one end of said support plate (3); the other end of said support plate (3) sliding with respect to the surface of said abutment (1); said support plate (31) provided with a clamping tooling (4), the position of which is adjusted by the rotation of said support plate (31), so as to enable said clamping tooling (4) to clamp different workpieces. workpieces.

A welding device for marine outfittings is described in accordance with claim 1, which has the feature that in the middle position above the abutment, there is an anti-skid plate, between the anti-skid plate and the abutment is rotationally set, and at both ends of the anti-skid plate, there are fixing bolts. The fixing bolts pass through the anti-slip plate and lock with the upper surface of the abutment, the anti-slip plate is in the shape of an arcuate groove, and there is an anti-slip stripe in the arcuate groove where the anti-slip plate is located.

A marine outfitting welding device according to claim 1, in particular, the adjusting frame 2 comprises a support frame 21, yes, the support frame 21 is firmly provided on the upper surface of the abutment 1, then, the support frame 21 is provided with a number of sets of moving slides 22, then, the moving slides 22 are provided with guide bars 221, and, the moving slides 222 are provided with sliding blocks 222 which form a sliding fit with the guide bars 221, and, furthermore, a driving member 23 is provided on the outside side of the moving slides 22 to drive the sliding blocks 222, and, the driving member 23 is provided to drive the sliding blocks 222. The sliding blocks 222 form a sliding fit with the guide rods 221, and furthermore, a driving member 23 is provided on an external side of the moving slots 22, and the driving member 23 is used to drive the sliding blocks 222.

![图片[2]-一种船用舾装件焊接装置及其焊接方法与流程-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768789483510_1.png)

4. A welding device for marine outfittings, according to claim 3, which has the following features, the driving member (23) contains a driving screw (231), both ends of the driving screw (231) are rotated with the support frame (21), the driving screw (231) is provided with a threaded block (232) above, the driving screw (231) drives the threaded block (232) to move, and a linkage (24) is provided on one side of the screw (232). The screw (231) drives the threaded block (232) to move, and the threaded block (232) is provided with a linkage (24) on one side of the threaded block (232); the linkage (24) contains a linkage block (241) which is fixedly connected to the threaded block (232), and there is a linkage block (242) on one side of the linkage block (241), which is capable of connecting any one of the sliding blocks (222) and the linkage block (241).

5. There is a marine outfitting welding device, of the type according to claim 3, which has the following characteristics: the adjusting frame (2) also contains lifting frames (25), the lifting frames (25) are between two opposing support frames (21), the lifting frames (25) have a number of lifting plates (251), the ends of each lifting plate (251) are connected to sliding blocks (222), the middle of each lifting plate (251) has a fixed half-arc hole (252), the fixed half-arc hole (252) is provided with a sliding half-arc hole (253), the fixed half-arc hole (252) is provided with a fixed half-arc hole (252). Each lifting plate (251) is provided with a fixed half-arc hole (252) in the middle of the plate (251), and the fixed half-arc hole (252) is provided with a sliding half-arc hole (253) above the sliding half-arc hole (253), the sliding half-arc hole (253) is able to play a limiting role in relation to the lifting plate (251), the fixed half-arc hole (252) is merged with the sliding half-arc hole (253) to form a complete fixed hole (254).

6. There is a marine outfitting welding device, as described in claim 1, characterised by the presence of a locking assembly (32) for the support plate (3). This locking assembly (32) is on top of a support plate (31) fixed at the bottom. The locking assembly (32) encompasses a locking slide (321). A locking slider (322) is provided in the locking slot (321). The locking slider (322) can be fixed relative to the locking slot (321). A mounting plate (323) is provided above the locking slide (322). At the bottom most support plate (31) and the mounting plate (323) are rotationally connected to each other. There are three pieces of the support plates (31) in total. And every two neighbouring support plates (31) are rotationally provided with each other.

7. There is a welding device for marine outfittings according to claim 5, which has the following features: the device has a clamping tooling (4) comprising a movable tooling (41) and a fixed tooling (42), the movable tooling (41) being provided on a central support plate (31) and the fixed tooling (42) being fixed to the top support plate (31) and the fixed tooling (42) being connected to a lifting plate (251) by means of fixing holes (254). The fixed tooling (42) is fixed on the top support plate (31), and the fixed tooling (42) is connected to the lifting plate (251) by means of fixing holes (254).

9. There is a marine outfitting welding device which is claimed according to claim 7 and which has the feature that the fixing tooling, that is, the fixing tooling (42), comprises a fixing post (421), which is fixedly connected to the top support plate (31), and the fixing spring (422) is provided at the end of the fixing post (421), and a second propelling cylinder (423) is provided outside the fixing post (421) and the fixing spring (422). At the end of the fixed column (421), a fixed spring (422) is provided, and at the outside of the fixed column (421) and the fixed spring (422), a second propelling cylinder (423) is provided.

Technical summary

The field to which the present invention belongs is the technical field of outfitting parts welding, which discloses a marine outfitting parts welding device, and discloses a welding method for the device, which has an abutment, with a fixed-point gripping mechanism above the abutment, the fixed-point gripping mechanism comprising an adjusting frame and a supporting sleeve, the supporting sleeve containing a plurality of mutually rotating supporting plates, the adjusting frame being able to drive one end of the supporting sleeve to move, and the other end of the supporting sleeve sliding relative to the abutment surface. The other end of the support plate slides relative to the surface of the abutment. The outfittings are supported on the underside by the skid plate, the fixing bolts on both sides of the skid plate are loosened before the welding outfittings are clamped and fixed, the welding outfittings are lifted above the abutment by means of lifting, the skid plate takes over the welding outfittings, the welding outfittings are then able to be pushed, the welding outfittings are rotated along with the underside of the skid plate and corrected to the weld outfittings, and the fixing bolts are tightened so that the skid plate is at the welding outfittings' position. The plate is then secured by tightening the fixing bolts; the plate can also be a wider curved groove to cater for different sizes of welding outfits.

Technology Developer: Chu Shu Furnace

Protected technology users: tree stoves

Technology development day:

Technical publication date: 2024/1/15

No comments