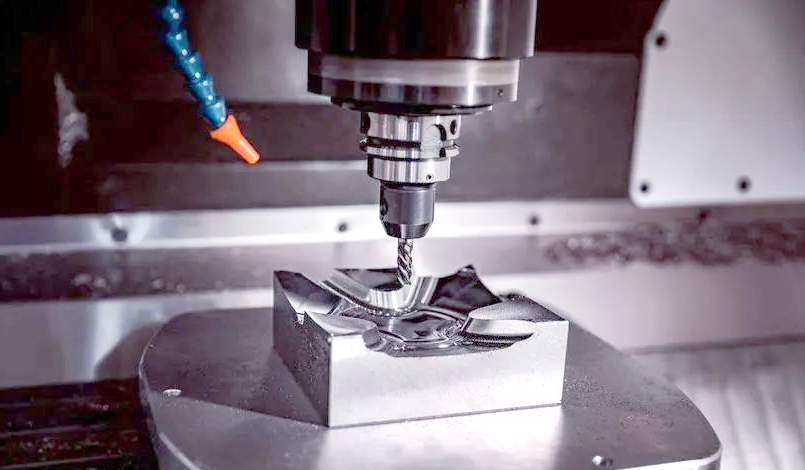

In the field of mould makingCNC machiningThe centre plays a very important role, it is mainly responsible for the core components of the mould, inserts and other precision machining of copper. The quality of these components is directly related to whether the mould is well formed or not, while the quality of brass machining has a direct impact on EDM machining. To ensure the quality of CNC machining, adequate preparation is one of the keys. This not only requires operators to have in-depth machining experience and comprehensive knowledge of the mould, but also places emphasis on effective communication during the working period, especially with the production team and co-workers.

![图片[1]-CNC加工中心操作全攻略:从准备到完成,一篇就够!-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768876804307_0.png)

The CNC machining process consists of a variety of key steps, including the reading of drawings and programme sheets, the transfer of programmes, parameter checks and so on. Before machining, it is necessary to ensure that the machining diagram of the new mould meets the corresponding requirements, and the data is clear, and the workpiece has the qualified mark of the quality department. After receiving the programme, we need to check the consistency of the datum of the workpiece with the datum of the drawing, and we also need to check each requirement carefully to make sure that the programme is consistent with the drawing. According to the material and size of the workpiece, assess the reasonableness of the programmer's choice of tools, if found unreasonable, should immediately notify the programmer to make changes, in order to improve machining efficiency and accuracy.

When clamping the workpiece, we should pay attention to the position of the yardstick, as well as the extension length of the nut bolt on the pressure plate must be just right, and the locking angle screws must not be pushed to the bottom. For copper processing, it is necessary to ensure that the number of materials opened before the machine with the programme to match the list, and check the receipt of the board screws are not tightened. If more than one piece of copper is to be received in one plate, it is necessary to check the direction and processing interference. According to the programme of the graphics and dimensional data to implement the workpiece clamping, while checking the programme and the bulk of the graphics and dimensions are not the same. At the time of clamping, the dimensions of the workpieces are checked for conformity with the programme, and the table and the underside of the workpieces are cleaned in order to guarantee the quality of the workpieces.

(7) in the code code this operation process, must ensure that the code will not collide with the tool, if necessary, then you can communicate with the programmer to carry out exchanges. At the same time, if the bottom of the pad placed on the square object, then the code must be accurately aligned with the position of the pad placed on the square object, in order to ensure that the force can achieve a balanced state.

When clamping in a vise, it is important to know the depth of machining of the tool in order to prevent the clamped position from being too long or too short.

9) The screws must be fully integrated into the T-block, and not only part of the thread must be used. If there is a need to connect the screws, half of the threads of the upper and lower screws must be used for each part of the joint. At the same time, the threads of the nut on the lever must also be used completely, not just a few threads.

When you are about to set the Z depth, it is important that you have a clear understanding of the position of the touch and the highest Z point as indicated on the programme sheet. After entering these data into the machine, it is necessary to check them again.

The next precaution is to clamp the tool:

1) The tool must be firmly clamped and the shank must not be too short.

Before clamping the tool, it must be checked each time that the tool meets the requirements. The length of the tool should be determined by the depth of machining indicated in the programme, usually 2mm longer than the depth of machining value, and it should be taken into account that the tool shank will not collide with other parts of the machine.

In the case of very deep machining, it is possible to negotiate with the programmer to use the double loading method, i.e. loading half to two thirds of the length first, and then loading longer after machining to a deeper position, thus improving the machining efficiency.

4) When using an extension nozzle, it is important to know key data such as the depth of the undercut and the length of the cutter required.

Before mounting the cutterhead on the machine, the taper fit must be wiped clean with a cleaning cloth, and the machine tool holder must be cleaned in order to prevent iron filings from affecting accuracy or damaging the machine.

(6) Generally, the means of tip-to-tool is used (except in special cases), and the instructions in the programme should be checked carefully at the time of tool setting.

(7) If there is an interruption in the programme or if it is necessary to set up the tool again, it is necessary to pay attention to whether the depth can be connected with the previous machining. Generally speaking, you can try to increase the height by 1mm and then adjust it according to the actual situation.

(8) for that rotary take-apart type of cutterhead, if the choice of water-soluble cutting fluid to implement cooling, then it is recommended that every half a month using lubricating oil soaked for a few hours to carry out maintenance, so as to ensure that the cutterhead internal parts can obtain very adequate lubrication, and thus prevent wear and tear.

Lastly, there are considerations for calibrating and aligning the workpiece:

When the workpiece is being dragged, it is necessary to pay attention to the maintenance of perpendicularity, firstly, one side should be dragged flat, and then go to the vertical side after that.

2) When the workpiece is centred, it must be centred twice and verified.

After the number of centring touches is divided, the accuracy of the centring is checked against the external dimensions given in the programme sheet and the dimensions on the drawing of the loose parts.

In the process of centring, all the workpieces must be centred to determine the zero position to ensure that the margins are the same on both sides. If there are special circumstances that require one side to be centred, this must be confirmed by the production team. The radius of the centring bar must be compensated for after centring.

The zero position of the centre of the workpiece is entered, and this series of operations is carried out in such a way as to ensure that it coincides with the centre of the three axes of the workstation's computer diagram.

▌ Precautions for Processing

In the process of machining, if the top surface of the workpiece has a margin that exceeds the normal range, when using a large knife to manually remove the margin, be sure not to remove too much, or else the quality of machining will be adversely affected.

(2) for the first knife processing, it has a vital role, this is because, it can be the tool length complement, tool diameter complement, programme, speed and a series of parameters such as whether it is correct to reflect, so, in the process of processing, must be particularly careful to operate and check, so as to avoid damage to the workpiece, tool and machine tool occurs.

After starting the machine again, one hand prepares to stop the machine, and the other hand controls the feed speed; when the tool is quite close to the surface of the workpiece, it stops again to check the remaining stroke of the Z-axis; finally, after the processing of the cutting line is smooth and stable, then the various controls are adjusted back to the normal state.

After entering the programme name, copy the name of the programme presented on the screen and check it against the programme sheet. When opening the programme, the size of the cutter should be carefully checked to see if it matches the programme sheet, and then the file name and cutter size should be filled in on the programme sheet immediately, rather than afterwards or beforehand.

In case of special circumstances such as changing tools or assisting in the adjustment of other machines, the NC technician should not leave when the workpiece is being roughened, but if he/she must leave, he/she should ask other NP team members to come back to check the workpiece regularly.

During the medium-lighting operation, the NC technician must pay special attention to the area that is not touched during the roughing phase, in order to prevent the tool from running into this area.

If the programme is interrupted during machining and it would be a waste of time to start again from scratch, the team leader and the programmer should be notified to modify the programme by cutting out the part that has already been executed.

In the event that a procedure presents an abnormal situation and you are not sure how to handle it, it is possible to raise it up and observe it, so that you can scrutinise the whole process and decide on the next course of action based on the results of your observations.

(9) During the machining process, the travelling speed and rotational speed advice given by the programmer can be used as a reference, but the NC technician needs to make adjustments flexibly according to the actual situation. Especially when roughing small pieces of copper, it is important to prevent the speed from being too fast to avoid loosening of the workpiece due to vibration.

During the machining operation, the NC technician must check with the drawing of the part in accordance with the prescribed cycle to ensure that the state of the part is in accordance with the expectations. If an abnormality is detected, the machine should be stopped immediately and the team leader should be notified for verification.

When using tools with a length of more than 200 mm, special attention must be paid to the margin, the depth of feed must be given special attention, the speed of rotation must be controlled, and the travelling speed must not be neglected in order to prevent the phenomenon of swinging tools. At the same time, the travelling speed at the corner must be strictly controlled.

(12) In the section of the programme which specifies that the diameter of the tool must be checked, the operator has to respond with the utmost care and to document the test results in detail. If it is out of tolerance, it should be reported immediately to the team leader or a tool change should be arranged.

13) When the machine is in automatic operation or idle, the operator must go to the workstation to know the remaining machining programme and prepare the appropriate tools for the next machining session to prevent unnecessary downtime.

(14) Process error is a common cause of wasted time, which covers the use of inappropriate tooling, machining sequence is not arranged properly, in the position of no need to process or not computerised machining of time, and the use of inappropriate machining conditions and so on. When encountering these problems, it is important to communicate with the programming and other relevant personnel in a timely manner.

During the machining period, we should pay close attention to the wear of the tool and replace the cutter or tool at the right time; after the replacement, we should make sure that the machining boundary is not smoothly connected.

▌ Matters to be noted after processing

1) Ensure that all procedures and instructions have been completed in accordance with the procedure sheets.

After machining, the shape of the workpiece is carefully checked for compliance with standards, and dimensional self-checks are carried out on the basis of loose parts drawings or process drawings, so that potential errors can be identified and corrected.

![图片[2]-CNC加工中心操作全攻略:从准备到完成,一篇就够!-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768876804307_2.png)

3) Comprehensively check all positions of the workpiece and notify the NC Team Leader immediately if there is any doubt.

When placing large workpieces, the team leader has to be notified in advance, and the programmer has to be notified, as well as the production team leader. ,.

(5) When the workpiece off the machine, be sure to pay attention to safety, especially large workpieces, to do a good job for the workpiece as well as the machine tool protection measures.

▌ Differentiated treatment of machining accuracy

Finishing surface quality requirements cover these, mould nut at the avoidance of empty space, block at the avoidance of empty space, copper male at the avoidance of empty space, the thimble plate support head hole at the avoidance of empty space, can eliminate the phenomenon of vibration knife pattern. Finishing dimensions, to all measurable dimensions of strict self-test, we must consider the long processing period of tool wear, especially the sealing bit, such as go batch front at the dimensional accuracy.

(3) As for the finishing process, in the range of available tools, priority should be given to the use of new tungsten carbide tools in order to ensure the quality of the finished product.

The modulus saving after finishing is determined according to the specific processing requirements in order to achieve the desired processing results.

After the completion of the work, various quality indicators, such as production and quality, are verified to ensure that the workpiece meets the requirements to be achieved.

In the case of sealing operations, tool wear should be controlled according to the requirements of the process to ensure precision and efficiency.

▌ Handover process

Get detailed information on the status of the last shift, which includes key information such as the progress of the process and the state of the mould.

Confirm that the equipment of the previous shift is in normal working condition to ensure that the next shift can be carried out smoothly.

Other essential handover and confirmation tasks such as the inventory of drawings and programmes and the handover of tools, gauges, jigs, etc., should also be completed.

▌ Workplace organisation and maintenance

(1) Strictly follow the 5S management requirements to implement, keep the workplace clean and orderly.

It is possible to arrange tools, in categories, gauges, in categories, jigs, in categories, workpieces and tools, in categories, so that it is easy to manage and so that it is easy to use.

3) Clean the machine regularly to ensure its stable performance and machining accuracy.

4) Maintain cleanliness of workplace floors to ensure a safe and accessible work environment.

Returning machined tools, unused tools and gauges to the warehouse in a timely manner saves space and facilitates management. The system is designed to save space and facilitate management.

The finished workpieces are sent to the quality control department or to the corresponding department for quality checking to ensure that the quality of the products meets the required standards.

No comments