Bolted and welded connections are the two most common types of connections in many mechanical structures.

This paper mainly with the help of the characteristics of the bolt, as well as the characteristics of the weld, to carry out a comparative analysis, and then summarise the advantages and disadvantages of the two main connection methods.

![图片[1]-螺接与焊接对比分析-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768961786261_0.webp)

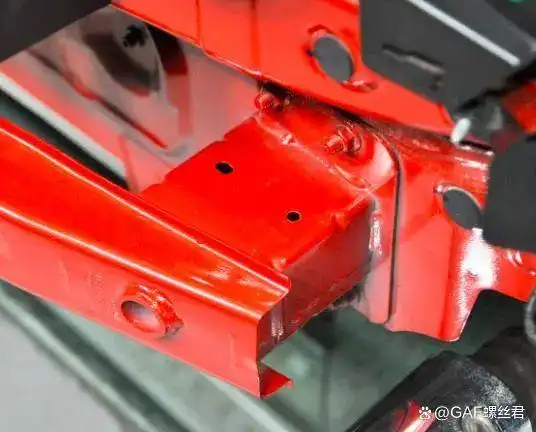

Detailed drawing of screwing and welding at the energy absorbing box

01 Welding

Welding has a spot welding, arc welding, laser welding and other categories, this article mainly to arc welding to be introduced, arc welding with the help of the heat generated by the arc caused by the welding rod and the weldment local melting, after cooling cohesion into a weld, through which the weldment is connected to an integrated whole, manual arc welding and automatic (or semiautomatic) submerged arc welding is the largest number of applications of the weldment connection method.

Welded structures have the following advantages over bolted connections:

These can be called its most outstanding advantages, its welded structure has a good airtight, its stiffness is quite large, and the integrity is also large, in addition, there are some junctions such as steel pipe and steel pipe Y-shaped and T-shaped connection, in addition to the weld, it is difficult to use the bolted connection or other connection methods.

![图片[2]-螺接与焊接对比分析-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768961786261_1.webp)

T-Connection Diagram

Weld connections also have some of the following shortcomings:

02 Bolt connection

![图片[3]-螺接与焊接对比分析-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768961786261_2.png)

It is the use of bolts as a fastening component to connect the parts that need to be connected to become a whole, which is known as the bolt connection. There are many types of bolted joints, including normal bolted joints and high strength bolted joints.

![图片[4]-螺接与焊接对比分析-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768961786261_3.webp)

Chassis screw-in application diagram

Types of bolts

There are two kinds of bolts for steel structure connection: ordinary bolts and high-strength bolts.

Normally, most of the common bolts are hexagonal head bolts, and their product grade is divided into three levels, which are A, B and C. In this case, for C grade bolts, Q235 steel can be used. In this, for C grade bolts, generally can use Q235 steel, it is made by hot rolled round steel, belongs to the crude bolt, and, this kind of bolts for the production of bolt hole requirements are relatively low, based on this, it is the most widely used in the field of ordinary bolts connected to this area, the number of applications is the most.

Ordinary bolts of product grade A and B belong to refined bolts, which have higher processing requirements for the bolt rod and higher processing requirements for the bolt hole, and the installation of ordinary bolts is usually carried out by means of manual wrenches, which do not require that there must be a prescribed pre-tension inside the screw.

The high-strength bolts used in steel structures have a specific meaning, which refers to the use of special spanners during the installation process to ensure that the screws have the required pre-tension, which results in the presence of the required pre-pressure on the contact surfaces of the plates to be connected.

Screws must be made of high-strength steel in order to increase the value of the pre-tensioning force that should be present in them. The common bolts described earlier, grade A and B, are still called ordinary bolts, even though they are also made of high-strength steel, and high-strength bolts are available in two performance grades, 8.8 and 10.9.

High-strength bolts are made of medium-carbon steel or alloy steel after quenching and tempering heat treatment, and have high strength. Among them, the 8.8 grade high strength bolts, its tensile strength fub is not less than 800N / mm2, flexion strength ratio of 0.8. 10.9 grade high strength bolts, its tensile strength is not less than 1000N / mm2, flexion strength ratio of 0.9.

Types of bolted connections

Bolt connection is divided into two categories: common bolt connection and high-strength bolt connection due to the time-saving and labour-saving characteristics of installation, the simplicity of the required installation equipment, and the skill requirements of construction workers are lower than the requirements of welders.

![图片[5]-螺接与焊接对比分析-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768961786261_4.png)

Each is further classified into three types according to the forces applied:

Commonly used in common bolted connections are rough bolted connections (Class C bolts), which include shear bolted connections, tensile bolted connections, and bolted connections subjected to both shear and tension. The shear connection is loaded by the shear of the screw and the pressure of the hole wall, while the tensile connection is loaded by the axial tension of the screw.

Rough bolts for shear connections are usually used only for secondary members that are not directly subjected to dynamic loads, such as braces, purlins, wall girders and small trusses, and then for connections of detachable structures that are not subjected to dynamic loads and for temporary fixing purposes.

On the contrary, the tensile properties of bolts are of the better type, and therefore they are often used in certain junctions where they are used for site installation and where they are subjected to tensile forces.

![图片[6]-螺接与焊接对比分析-大连富泓机械有限公司](/wp-content/uploads/2026/01/1768961786261_5.webp)

Advantages and disadvantages of bolted connections

Bolted joints have the advantage of being easy to construct, easy to install and easy to dismantle, and are suitable for the kind of structures that need to be installed and dismantled as well as for temporary connections.

Bolt connection has such disadvantages, first, to open holes on the plate, and in the assembly needs to be directed at the hole, which will increase the workload of manufacturing, and for the manufacture of precision is a high demand; second, bolt holes will lead to the weakening of the cross-section of the member, and the connected parts usually need to lap each other or additional auxiliary connecting plate, that is, the angle, so the construction of the more cumbersome, and will be More steel consumption.

Screw Welding Comparison Summary

03 Summary

Screwed connections play an extremely important role in joining, and welded connections also play a key role, depending on the part of the application, on strength requirements, on space constraints, on costs, on functional requirements, etc.

As in the automotive sector, the body-in-white is still welded as the main method, with screwing as a secondary method. In the case of the chassis and the vehicle, screwing is the main method of connecting the various systems (the body-in-white is carried out in the welding shop and the vehicle is assembled in the final assembly shop). (Some of the material for this article was taken from the Internet (the body-in-white is welded in the welding shop and the complete vehicle is assembled in the final assembly shop).

No comments