Stainless steel riveting technology supplier for thin sheets: your reliable partner for precision metal joining

In today's industrial world, where lightness, strength and precision are increasingly required.Thin plate stainless steel riveting technologyhas become an indispensable core process for many industries. Whether it's a delicate component of a medical device, a critical connection in an automotive exhaust system, or a rugged enclosure for a high-end electronic device, the need forReliable, efficient and aesthetically pleasing metal joining solutions. This is exactly what the professionalRiveting technology supplier for thin sheet stainless steelThe core values of the

Why is thin sheet stainless steel riveting technology so important?

Thin sheet stainless steel (usually referred to as stainless steel plate with a thickness between 0.5mm and 3.0mm) is known for its excellentCorrosion resistance, high strength-to-weight ratio, hygienic and easy-to-clean properties, and a modern look., is widely used:

-

Automotive Industry: Exhaust system components, sensor housings, trim parts, new energy battery pack components.

-

Medical equipment: Surgical instruments, equipment cases, trolley frames, precision instrument housings.

-

Food and beverage processing: Worktops, containers, pipes, conveyors.

-

Electronic appliances: Chassis cabinets, server enclosures, precision brackets, connector components.

-

Industrial equipment: Shields, panels, ventilation ducts, precision parts.

![图片[1]-薄板不锈钢铆焊技术供应商:您精密金属连接的可靠伙伴-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/07/QQ20250718-201719.png)

Reliably joining thin sheets of stainless steel together.Riveting technology (combining the advantages of riveting and welding) Demonstrate unique advantages:

-

Overcoming Welding Challenges: Thin plate welding is highly susceptible to problems such as distortion, burn-through, and large heat-affected zones. Rivet welding effectively reduces heat input and significantly reduces the risk of distortion through the combination of mechanical connection (riveting) and localised welding.

-

Enhances connection strength and sealing: Precision welding (e.g. laser welding, micro-beam plasma welding, resistance spot welding) is supplemented with precision welding at critical stress points or where sealing is required to ensure the strength, rigidity and gas/liquid tightness of the connection.

-

Adaptation to complex structures and heterogeneous materials: For complex structures or where it is necessary to join stainless steel to other metals (e.g. aluminium, copper), rivet welding offers a more flexible and reliable solution.

-

Balance efficiency with aesthetics: Riveted sections allow for quick assembly, while partial welding provides a smooth, clean weld appearance that meets the aesthetic requirements of high-quality products.

Key values in choosing a supplier of specialist thin sheet stainless steel riveting technology

When faced with the need for precision thin sheet stainless steel riveting, choose an experienced and skilledvendorCritical:

-

Deep technical deposits and process expertise:

-

Proficient in all kinds of stainless steel for thin plateRiveting process(e.g. pressure riveting, pull riveting, self-pierce riveting) andPrecision welding process(Laser welding, micro-beam plasma welding, resistance spot welding, TIG welding).

-

In-depth understanding of the machinability and weldability of different stainless steel grades (e.g. 304, 316, 430, etc.).

-

Possesses the solution to the thin plate processingAnti-deformation, anti-burn-through, guaranteed dimensional accuracyA database of proven programmes and processes for core challenges such as.

-

-

Advanced equipment and process control:

-

Equipped with high-precision CNC laser cutting machines, precision stamping equipment, automated riveting equipment and advanced welding power sources (e.g. high-precision laser welding machines, micro-beam plasma welding machines).

-

enforceprocess control(SPC) andQuality Assurance System(e.g. ISO 9001) to ensure consistent and reliable dimensional accuracy and connection quality of each product.

-

-

Strong design and engineering support capabilities:

-

Ability to intervene early in the product design process to provideDesign for Manufacturability (DFM) It is recommended to optimise the design of the connection structure to improve product performance and reduce costs.

-

According to customer drawings or samples, providecustomisationThe riveting and welding process plan and jig design.

-

-

Comprehensive precision manufacturing services:

-

provide information fromPrecision undercutting (laser cutting/stamping) -> Forming (bending/stamping) -> riveted joint -> Surface treatment (optional, e.g. electrolytic polishing, sandblasting) -> Precision Cleaning -> strict quality controls one-stop shop to streamline the customer supply chain.

-

-

Strict quality control:

-

Use of high-precision testing equipment (such as quadratic imager, coordinate measuring machine, weld nondestructive testing equipment) for all-round inspection of riveting strength, weld depth, weld quality, dimensional tolerances and appearance.

-

-

Rapid Response and Flexible Production:

-

Ability to respond flexiblyLow volume, high variety, fast deliverymarket demand, and become a strong backing for the rapid iteration of customers' products.

-

Our core competence: to be your trusted partner

As a deep-rootedThin plate stainless steel riveting technologySpecialist supplier in the field, we are committed to:

-

Providing cutting-edge solutions: Continuous investment in advanced equipment (such as fibre laser welding machine, precision servo pressure riveting machine) and process research and development, to overcome the technical barriers of thin plate connection.

-

Guaranteeing excellence: Establish a strict quality control system throughout the entire process to ensure that each deliverable meets or exceeds customer expectations.

-

Focus on customer needs: Understanding your application scenarios and pain points, we provide the most cost-effective and reliable customised riveted connection solutions.

-

Optimising value delivery: Through efficient manufacturing processes and supply chain management, we help you shorten your time-to-market and reduce overall costs.

![图片[2]-薄板不锈钢铆焊技术供应商:您精密金属连接的可靠伙伴-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/07/QQ20250718-201839-800x694.png)

Our Service Process

-

Demand communication: Get an in-depth understanding of your product requirements, material specifications, performance specifications and budget.

-

Programme design and review: Provide process solutions, feasibility analysis and quotation based on DFM concept.

-

Sample making and confirmation: Quickly produce samples for you to verify design, workmanship and quality.

-

Batch production and process monitoring: Strictly execute the production according to the confirmation programme and monitor the key quality points throughout the process.

-

Full quality control and on-time delivery: Execute final strict inspection to ensure perfect delivery of products.

-

Ongoing support: Provide perfect after-sales service and technical support.

Wide range of application areas

Our precision thin sheet stainless steel riveting technology has been successfully applied to:

-

Automotive exhaust manifolds, sensor brackets

-

Medical endoscope parts, surgical instrument joints, equipment housings

-

Food-grade containers, pipe flange connection

-

Server chassis, 5G equipment shields, precision electronic mounts

-

Industrial instrument panels, shields, ventilation components

Contact us immediately!

When your project involvesStainless steel sheetand requiresReliable, precise and aesthetically pleasing connectionsWhen looking for a technically strong, experienced, qualityRiveting technology supplier for thin sheet stainless steelis the key to success.

Let us be your trustworthy partner with exquisite riveting and welding technology to build stronger, more precise and competitive products together!

[Your Company Name] - Specialising in thin sheet stainless steel precision riveting solutions

Optimisation Tip (for reference).

Title. Core keywords have been included.

Main article. Natural, multiple incorporation of core keywords (

Riveting technology supplier for thin sheet stainless steel,Stainless steel sheet,Rivet welding technology,vendor) and its variants (Precision metal connections,Stainless steel welding,Riveting process,Customised solutions,Precision manufacturing services). The Application Scenarios section also contains related industry words.Clear structure. Use subheadings (H2, H3) to organise content for easy reading and search engine comprehension.

Content value. Answers possible user questions (Why is it important? Supplier value? Service process?) , providing practical information.

Call to Action (CTA). The ending encourages connections.

Meta description (recommended). Write a meta-description of about 155 characters for the web page that contains the main keywords, summarises the core content of the article and attracts clicks. For example, "Professional thin plate stainless steel riveting and welding technology supplier, providing precise and reliable connection solutions. Solve the problem of thin plate welding deformation, used in automotive, medical, electronic and other industries. Customised service, strict quality control."

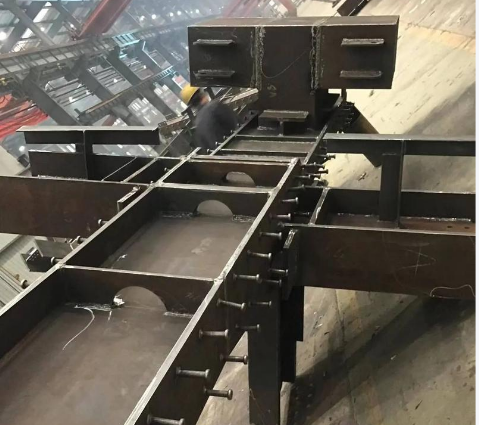

Image ALT tag. If the article is illustrated, make sure the ALT tag contains relevant keywords (e.g. "precision thin stainless steel laser welding samples", "automated stainless steel riveting production line").

No comments