This is an article dedicated to "Machining in China" and "Machinery Manufacturing in China".

Title: Machining and Machinery Manufacturing in China: An Engine and Innovative Force in the Global Supply Chain

Description: Discover the rise of China's machining and mechanical engineering industry, its core strengths, technological innovations and how to find quality suppliers. Find out why "Made in China" is a key player in the field of precision components and complex equipment.

Main article:

In the grand blueprint of global industrialisation, "China machining" and "China machinery manufacturing" have become indispensable keywords. With decades of rapid development, a large industry, rising technology levels and significant supply chain advantages, China has firmly established itself as the world's core manufacturing hub. Whether it is precision customised components or complex complete sets of equipment, China's machining and manufacturing capabilities are profoundly influencing the global industrial chain.![图片[1]-中国机械加工与机械制造:全球供应链的引擎与创新力量-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/07/QQ20250720-185627-800x550.png)

I. Machining in China: synonymous with precision and efficiency

"China Machining" covers an extremely wide range of areas, including but not limited to:

-

Turning, milling, drilling, grinding: These basic but vital machining processes have a high degree of maturity and popularity in China, and are capable of meeting the needs of a wide range of metallic and non-metallic components, from simple to complex, from standard to customised.

-

CNC machining: This is the core competence of modern "Chinese machining". China has the largest number of CNC machines (machining centres, turning centres, wire-cutting, laser cutting, etc.) in the world, covering high, medium and low-end markets. Strong CNC capability ensures that machiningHigh accuracy, consistency, complexity and efficiency.

-

Speciality machining: Such as electric discharge machining (EDM), laser machining, and water jet cutting for difficult-to-machine materials or special structures.

-

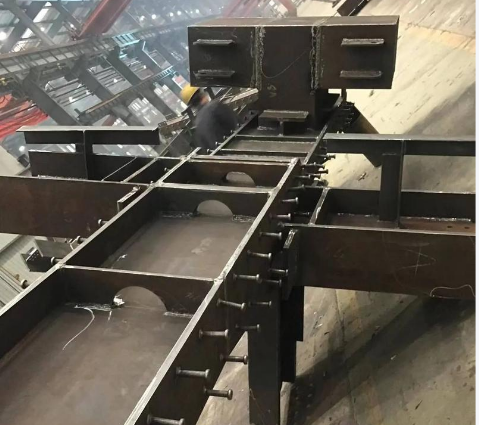

Sheet metal working: Including cutting, bending, stamping, welding, etc. Widely used in chassis cabinets, structural parts manufacturing.

China's core strengths in machining are:

-

Huge capacity and economies of scale: The ability to take large orders significantly reduces unit costs.

-

A well-established supply chain network: From raw materials (steel, aluminium, special alloys, etc.) to tools, jigs and equipment maintenance, the supporting industries are extremely mature, easy to procure and responsive.

-

Skilled labour pool and skills upgrading: While competition for top talent is fierce, China has a large base of skilled workers and an improving vocational training and skills certification system.

-

Cost-effectiveness: The overall costs (labour, equipment depreciation, management, land, etc.) are still remarkably competitive compared to many developed countries while maintaining quality.

-

Rapid response and flexibility: Numerous companies are able to quickly adjust their production lines to suit the customised needs of small batches and multiple varieties.

II. China's Machinery Manufacturing: From Basic Equipment to High-end Smart Manufacturing

"Chinese machinery manufacturing" is a more macro concept that refers to the production of complete mechanical equipment, production lines or industrial systems using a variety of machining technologies, assembly processes and systems engineering. This includes:

-

General equipment manufacturing: Such as pumps, valves, compressors, bearings, gear drives, etc.

-

Manufacture of specialised equipment: Industry-specific equipment, such as construction machinery, agricultural machinery, textile machinery, printing machinery, food processing machinery, plastics machinery, etc.

-

Manufacture of machine tools: China itself is a major producer of machine tools, supplying the country and exporting them.

-

Automation and Intelligent Equipment: This is the current "China Machinery Manufacturing" focus on the direction of development, including industrial robots, automated production lines, intelligent testing equipment, logistics and warehousing automation systems.

-

Manufacture of key components: Provide core precision components for domestic and international high-end equipment (e.g. aviation, energy, medical equipment).

Evolution and Advantages of China's Machinery Manufacturing Industry:

-

A leap from "quantity" to "quality": Early on, it was mainly focused on low-end and OEM, but now it is making every effort to transform and upgrade to high-end, independent brand and intelligence.

-

Government strategic support: National strategies such as "Made in China 2025" clearly list high-end CNC machine tools and robots, advanced rail transport equipment, energy-saving and new energy vehicles, electric power equipment, etc. as key development areas, and invest huge resources.

-

Driven by technological innovation: Local enterprises and research institutes have continued to invest in R&D in areas such as materials science, design software, control systems, and additive manufacturing (3D printing), and have significantly enhanced their innovation capabilities.

-

Complete industrial ecology: A relatively complete industrial chain has been formed from basic R&D, design, core parts manufacturing, complete machine assembly to sales and after-sales service.

-

Strong export capacity: Machinery and equipment made in China are selling well in the global market, especially in developing countries and emerging economies, thanks to their cost-effectiveness and ever-increasing quality.

![图片[2]-中国机械加工与机械制造:全球供应链的引擎与创新力量-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/07/QQ20250720-185504-800x528.png)

III. How to Find Reliable Chinese Machining and Manufacturing Partners

Facing a large number of China suppliers, it is critical to select quality "China Machining" factory or "China Machine Manufacturing" business:

-

Clarify needs: Clearly define your product specifications, quality standards (e.g. ISO 9001, AS9100, IATF 16949, etc.), quantities, budgets and schedules.

-

In-depth research:

-

Utilising B2B platforms: Such as Alibaba International, Made in China, etc., but screen the information carefully.

-

Industry trade shows: Participate in large-scale exhibitions such as the China International Industry Fair and the Canton Fair to directly contact suppliers.

-

Professional Recommendation and Review: Obtain information and conduct qualification audits through industry associations, consulting firms or third-party factory inspection services.

-

-

Critical assessment:

-

Technical skills: Examine their equipment list, processing accuracy, engineering team strength, case experience (especially whether they have done similar products).

-

Quality system: Verify their quality accreditation certificates and learn about their quality control processes and laboratory capabilities.

-

Production Management: Evaluate their production planning, supply chain management, and site management level (can be done through video factory inspection).

-

Communication and Service: Examine their responsiveness, language skills, smoothness of technical communication, and problem-solving approach.

-

Compliance: Find out about their environmental, labour and other compliance.

-

-

Samples and small batch trial production: Before determining a large order, be sure to request a sample or small batch trial production, which is the most direct way to test the real ability of the supplier.

-

Establish clear contracts: Clarify the terms and conditions of the technical agreement, quality standards, delivery period, payment method, intellectual property protection, and liability for breach of contract.

IV. Looking ahead: challenges and opportunities

The future of China's machining and manufacturing industry is full of opportunities and challenges:

-

Opportunity: Industrial upgrading (intelligent manufacturing, green manufacturing), expanding domestic demand market, overseas market opportunities brought by the "Belt and Road" construction, and breakthroughs in technological innovation.

-

Challenge: Rising labour costs, shortage of high-end talents, core technologies (e.g. high-end CNC systems, precision sensors) still awaiting breakthroughs, intensified international competition, and uncertainties arising from the restructuring of the global supply chain.

reach a verdict

"Chinese machining" and "Chinese machine building" have long since moved beyond the single label of "low cost". They representStrong manufacturing base, ever-improving technological capabilities, increasingly sophisticated supply chain ecosystem, and ambition to move up the global value chain. For global buyers, China remains an important source for meeting the demand for diverse, cost-effective machinery parts and equipment. The key to success lies in deeply understanding the complexity of this market, applying effective strategies, and finding and managing excellent partners who truly possess technical strength, quality assurance and business reputation. China's machinery industry is accelerating on the path of intelligent and high-quality development, and its global influence will continue to deepen.

No comments