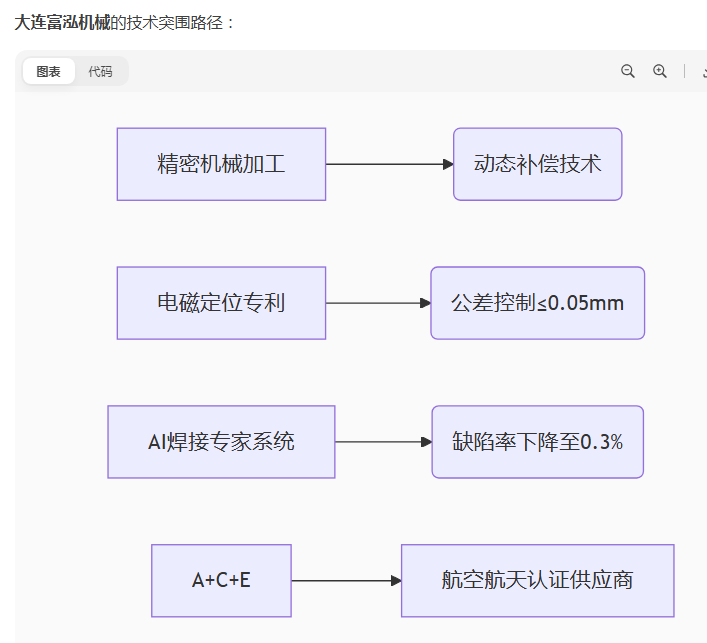

Manufacture of machinery and equipment: How to choose a reliable industrial partner?

1 Introduction: Quality begins with choice

In the global industrial chain, machinery and equipment manufacturing is the cornerstone supporting the development of various industries. From an efficient production line to a huge construction machine, a reliable machinery and equipment manufacturer is indispensable behind it. With so many suppliers out there, how to make a wise choice becomes the critical first step to ensure the success of your project and increase your ROI. This article will reveal the core elements of choosing a professional machinery and equipment manufacturing partner.

2 Core competencies of specialised machinery and equipment manufacturers

The value of a professional machinery and equipment manufacturer is reflected in the comprehensive capabilities of multiple dimensions.

2.1 Advanced production and testing equipment

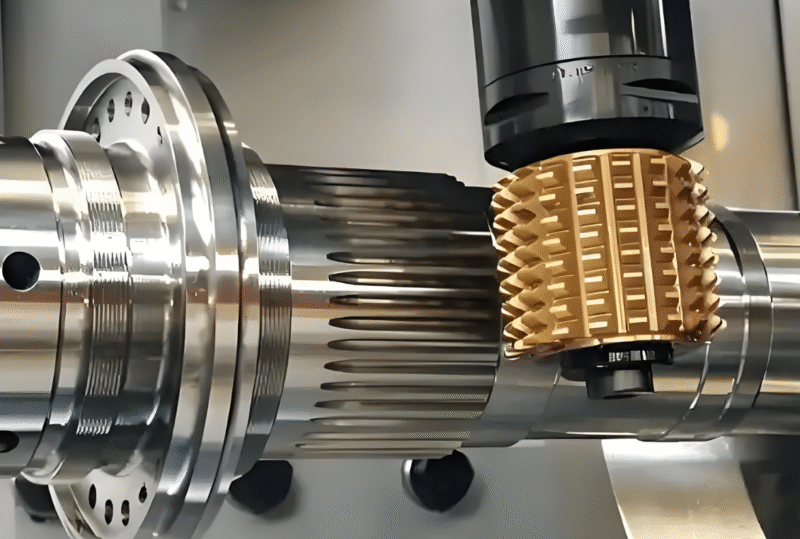

CNC machining centres: ensure high precision and repeatability in the machining of complex parts-9.

Automated Welding Robot: Ensures consistent and efficient welding quality-3.

CMM & Laser Tracker: Provide accurate quality data support for large-scale heavy equipment manufacturing.![图片[1]-机械设备制造:如何选择可靠的工业合作伙伴?(在评估机械设备制造商时,最常被忽视的因素是什么?)-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/06/QQ20250625-204151-800x406.png)

2.2 Comprehensive technical qualification and certification

Qualifications are the cornerstone of trust. Professional manufacturers usually hold:

ISO 9001 quality management system certification: ensures that every step from design to delivery is well documented-9.

Industry-specific certifications: such as CE (European Safety Certification), API (American Petroleum Institute Certification), etc., are passports for products to enter specific markets-6.

Certification of welding systems, such as EN 15085 (rail vehicle welding) or ISO 3834 (quality requirements for fusion welding of metallic materials), is essential for the manufacture of heavy equipment.

3 Specificities and Challenges of Heavy Equipment Manufacturing

Heavy equipment manufacturing areas, such as the production of mining machinery, large harbour machinery or metallurgical equipment, require a higher degree of complexity and specialisation.

Capacity to handle large structural parts: Manufacturers need to have key equipment such as large gantry mills and large plate rollers to complete the machining and forming of oversized workpieces.

Extraordinary welding technology: In the manufacture of heavy equipment, many welds are critical and require special welding processes by qualified welders, sometimes with quality verification through non-destructive testing (e.g. ultrasound or X-ray)-3.

Project Integration Management Capability: Large equipment is often produced modularly and shipped in batches, requiring manufacturers to have extremely strong project management and logistics coordination capabilities.

4 Success stories: how trust is built

We have worked with one of the world's leading mining companies to provide their core crushing and screening systems.

Challenge: The harsh working environment of the equipment requires high wear resistance of the material and reliability of the whole machine.

Solution: Our engineers use finite element analysis for structural optimisation at the design stage, use ultra-high strength steel plates for key stress components during the manufacturing process of machinery and equipment, and carry out rigorous flaw inspections on all welded joints.

Achievement: The equipment has been running trouble-free for more than 10,000 hours, which is highly recognised by the customer and confirms our profound strength in the field of heavy industry equipment manufacturing.

5 Frequently Asked Questions

Q: What are the most commonly overlooked factors when evaluating machinery and equipment manufacturers?

A: Often it is the robustness of the supply chain. A robust supply chain ensures that there are no shortages of raw materials and key components at critical moments in production, which is an important guarantee of on-time delivery.

Q: How can I verify a manufacturer's actual production capacity?

A: In addition to checking promotional materials, on-site factory inspection is an essential part. Focus on the factory's 5S management, equipment maintenance status and the quality status of work-in-progress.

Q: Can you customise to our specific needs?

A: Of course. Customised design and highly adaptable production capabilities are one of the core services of modern machinery and equipment manufacturing. We can work closely with your technical team throughout the entire process, from conceptual design to product delivery.

6 Conclusion

Choosing a suitableManufacture of machinery and equipmentpartner, is an important strategic decision. By focusing on their technical equipment, qualifications, industry experience and project management expertise, you can make your choice with greater confidence. We look forward to being your reliable industrial partner with our extensive experience and technical expertise in the fields of mechanical engineering and heavy equipment manufacturing.

No comments