comprehensive analysisMachining process and machining processThis article is a must-have guide to understanding modern manufacturing! This article takes you through the entire process, from drawing analysis and process planning to specific processes such as turning, milling, drilling and grinding, and is an essential guide to understanding modern manufacturing. Text Contents Introduction Machining is the cornerstone of mechanical engineering, shaping raw metal or non-metallic blanks into parts that meet the requirements of precision drawings through a series of organised technical operations. Understanding its systematic “process flow” and specific “machining processes” is essential for optimising production, controlling costs and quality. This article will serve as your in-house training manual, giving you a thorough insight into the heart of manufacturing.

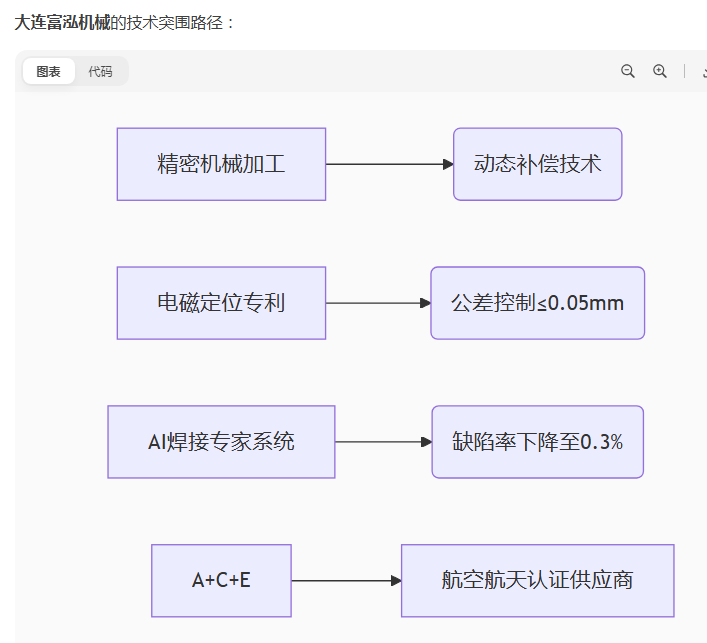

I. Core concepts: process flow vs. processing process Process flow: refers to the macro path and sequential arrangement of parts processing. It defines “what to do first and what to do later” and is the strategic blueprint for the entire production activity. Process: This refers to the cutting action and the process of changing shape at the micro level in each process. It solves the problem of “how to do it”.![图片[1]-机加工的工艺流程和加工过程详解:从毛坯到精件的制造之旅-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/11/QQ20251102-193919-800x455.png)

Second, the complete process of machining (macro-process) The birth of a standard part, usually follow the following eight steps: drawing analysis and digestion: a comprehensive understanding of the technical requirements of the parts drawing, including dimensional tolerances, shape and location tolerances, surface roughness, material and heat treatment requirements. Process review and selection of blanks: Evaluate the drawings for process reasonableness and determine the form of blanks (e.g. castings, forgings, profiles, etc.). Process Route Development: This is the core planning. Determine the machining sequence, e.g. “face first, hole second”, “rough first, finish first”, “datum first”. Process design: Selection of equipment, fixtures, tools and gauges for each process, and determination of cutting parameters (speed, feed, depth of cut). CNC Programming (if required): Preparation of the machining programme for the CNC machine. Production preparation: Preparation of all the above production materials. Machining execution and process inspection: Operators execute machining according to the process documents, and carry out self-inspection and mutual inspection. Final Inspection and Storage: The quality inspector will measure the finished products and put them into storage after passing the inspection.

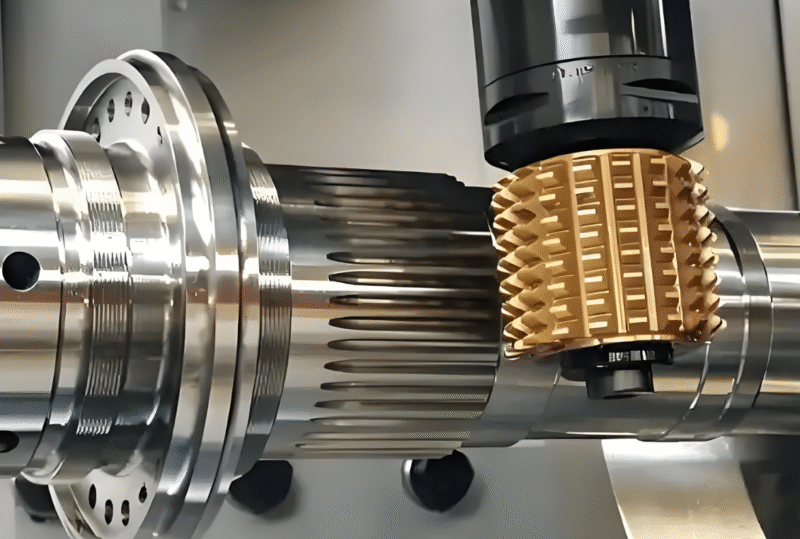

Third, the common machining process (micro-operation) This is the process route to the specific link, mainly including the following types of typical processing methods: turning: workpiece rotation, tool movement. Mainly used in the processing of rotating body parts (such as shafts, discs, sets), to complete the outer circle, bore, end face, threads and other features. Milling: The tool rotates and the workpiece moves. It is suitable for machining flat surfaces, grooves, complex cavities and curved surfaces. It is one of the most widely used machining methods. Drilling and Boring: Drilling is used to machine holes; Boring is used to enlarge and refine existing holes to obtain high accuracy in hole diameter and position. Grinding: The use of grinding wheels for finishing can achieve very high dimensional accuracy and excellent surface roughness. WEDM and EDM: Special machining methods for high hardness materials or complex moulds.

Fourth, how to develop the optimal process? The optimal process is a balance of quality, efficiency and cost. The key is: the principle of unity of reference: as far as possible to use the same set of positioning datum to complete most of the processes. Reduce the number of clamping: By using composite tools or 5-axis machine tools, a single clamping to complete multi-face machining. Reasonable arrangement of heat treatment: Annealing, quenching, tempering and other processes are arranged in the right place to eliminate internal stresses and ensure material properties.

Conclusion Mastering systematic machining processes and procedures is fundamental to ensuring product quality and production efficiency. For machine builders, this is an internal skill; for companies that need to outsource machining, this can help you evaluate and communicate with suppliers in a more professional manner. When you need to outsource this part of the work, how to manage it efficiently becomes a new challenge - this is exactly the pain point that machining outsourcing app and professional outsourcing machining services for machine shops are trying to solve.

No comments