Machining Machines and Equipment: From turning, milling and grinding to CNC, read how to choose in one article |

Meta Description: Don't know about machining equipment? This article provides a comprehensive overview of the functions and selection points of core equipment such as lathes, mills, grinders, CNC machining centres, etc., to help you evaluate supplier capabilities or plan equipment purchases.

Machining Machines and Equipment Book: The Core Force Defining Modern Manufacturing

Introduction:

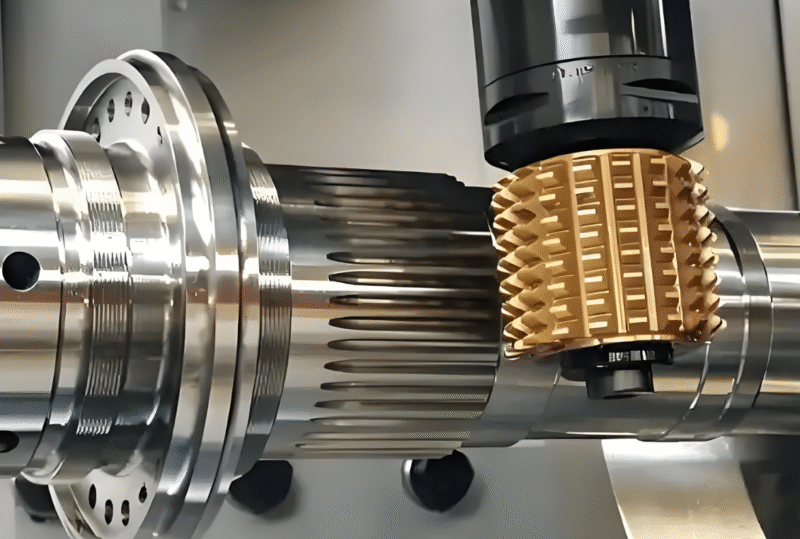

“If you want to do a good job, you must first sharpen your tools.” Machining equipment is the “tool” of a machine shop, which directly determines its machining capability, accuracy level and business scope. Whether you're looking to purchase equipment to build your own shop, or you're a customer evaluating the strength of your suppliers, it's important to understand the mainstream machining equipment. This article will bring you a quick introduction to these “steel warriors” of modern manufacturing.

I. Conventional/general-purpose machine tools (basic and supplementary)

lathes

Function: Mainly machining rotary body parts (such as shafts, rods, sleeves) for external round, internal hole, thread, end face, etc.

Features: It is one of the most basic equipment in machining.

machining centre

Function: Used for machining flat surfaces, grooves, gears, splines and various complex profiles.

Features: Tool rotation is the main motion and workpiece movement is the feed motion.

drilling machine![图片[1]-机加工机器设备大全:定义现代制造的核心力量-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/11/QQ20251102-193538.png)

Function: Mainly used for drilling, reaming, reaming and tapping.

Characteristics: Simple structure, strong specialisation.

grinder

Function: Finishing with grinding wheels achieves extremely high dimensional accuracy and surface finish.

Type: Surface grinder, cylindrical grinder, internal grinder, centreless grinder, etc.

II. CNC machine tools (the mainstay of modern machining)

CNC machining centre

Function: Milling, drilling, boring, tapping and other functions in one, with automatic tool changer, one clamping can complete multiple processes.

Core Advantages: High precision, high efficiency, automation, suitable for processing complex parts.

Classification: Vertical, horizontal, gantry, three-axis, four-axis, five-axis linkage. Five-axis machining centres are a key indicator of a factory's high-end machining capabilities.

CNC lathe (numerically controlled lathe)

Function: Numerically controlled lathe for automatic precision machining of complex rotary parts.

Derivation: Combined turning and milling centre with further integrated milling functions for greater functionality.

wire erosion machine

Function: EDM cutting using a moving wire (electrode), especially suitable for processing high hardness metals and complex moulds.

Classification: Fast walking wire, slow walking wire (higher precision).

laser cutting machine

Function: Using high energy laser beam to cut metal sheet, fast speed, high precision, no need to open mould.

Third, how to choose machining machines and equipment according to the business?

Start-ups/Small Workshops: Can start with one or two CNC machining centres and CNC lathes, covering most general parts machining needs.

Medium-sized specialised factories: On the basis of general-purpose CNC equipment, add special equipment such as wire-cutting and grinding machines, and consider 4-axis/5-axis equipment to undertake high value-added orders.

Large/Integrated manufacturers: need to be equipped with a complete chain of equipment, including large-scale gantry milling, horizontal machining centres, turning and milling and a variety of testing equipment, to form a one-stop solution capability.

Summary:

A machine shop's equipment list is its “resume”. Customers can roughly judge its technical strength by looking at the brand, model, quantity and newness of the equipment. For a machine shop, continued investment in advanced machining equipment is an inevitable choice for improving competitiveness and accepting higher-value machining orders.

Our equipment strength promises:

[Your Website Name] has always been committed to technological upgrading, with advanced equipment clusters including 5-axis linkage machining centres, high-precision CNC lathes, slow-feeding wire-cutting, etc., to ensure that we can provide customers with a full range of precision machining services from simple to complex, from prototype to batch.

Extended Reading:

How do machinists take orders? How do machining orders usually get taken?

Looking for Machining Outsourcing Manufacturers? Machining Outsourcing Machining Network Full Tips

No comments