parseequipment manufacturingat the heart of the industry as an industrial mother machine. Explore how smart manufacturing, service transformation and supply chain optimisation are reshaping this industry and opening up new growth opportunities for businesses.

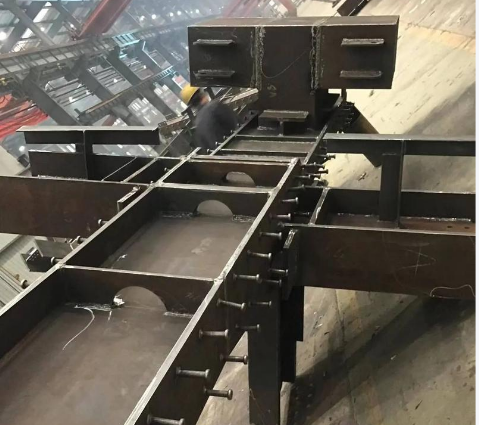

Text: If industry is the skeleton of the modern economy, then the equipment manufacturing industry is the manufacture of the skeleton of the “mother machine”. It is responsible for the production of all walks of life required for the work of the machine, major technical equipment and automated production lines, is an important symbol of a country's industrialisation level and comprehensive national strength.![图片[1]-装备制造业:国之重器,如何通过智能制造决胜未来市场-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/11/QQ20251002-201423.png)

1. Understanding the scope and importance of the equipment manufacturing industry The equipment manufacturing industry covers a wide range of industries, including: power equipment: such as gas turbines, hydraulic turbines, nuclear power units. CNC machine tools: the “teeth” of modern manufacturing, responsible for precision machining. Engineering machinery: such as excavators, cranes, shield machine. Agricultural machinery, textile machinery, printing machinery and other special equipment. It provides a powerful technical means and material basis for the national economy and national defence construction.

2. Intelligent manufacturing is the core driving force Under the wave of Industry 4.0, the equipment manufacturing industry itself is taking the lead in intelligent upgrading. Flexible manufacturing system: able to quickly adjust the production line to adapt to the small batch, multi-species market demand. Application of additive manufacturing: 3D printing technology is used to manufacture complex parts prototypes, and even directly produce the final product, greatly reducing the development cycle. Data-based optimisation: Data from the operation of equipment on the client side is fed back to the manufacturer to optimise the design and performance of next-generation products.![图片[2]-装备制造业:国之重器,如何通过智能制造决胜未来市场-大连富泓机械有限公司](https://cndlfh.com/wp-content/uploads/2025/10/QQ20251002-200855-800x540.png)

3. Transformation from “selling products” to “selling services” Leading equipment manufacturers are no longer just selling equipment on a one-off basis, but are shifting to providing full life-cycle services. Remote operation and maintenance services: Through the Internet of Things platform, provide customers with 24/7 equipment status monitoring and remote diagnosis. Finance lease and pay-per-use: Reducing the initial investment threshold of customers and binding the interests of manufacturers and customers.

4. Enhancing supply chain resilience Equipment manufacturing industryChains are long and the stability of the supply chain is critical. Global layout and regional backup are becoming mainstream strategies to cope with potential geopolitical risks and contingencies. Summary: The equipment manufacturing industry is at a crossroads of transformation driven by both technological revolution and business model innovation. Only by actively embracing smart manufacturing, deepening service transformation and building a tough supply chain, can enterprises be invincible in the field of “the most important weapon of the nation”.

No comments