What do you know about industrial photogrammetry for large part inspection?

Industrial photogrammetry is one of the more popular non-contact, wide-area scene measurement techniques today, with relatively mature technology development and a wide range of applications.

Research on the method of detecting surface texture defects on machined parts

Machining parts surface texture defects detection of the method of research.doc, machining parts surface texture defects detection of the method of research Abstract: With the improvement of China's industrial development level, the degree of modernisation of industrial production is increasingly high.

Detailed Boring Process: Process Analysis from Rough Boring to Finish Boring

01 Boring Standard boring, as an integral part of a machining centre, is designed to ensure the dimensional and form accuracy of the hole system, thereby correcting errors that may have arisen in previous processes. This type of machining is mainly used for critical mating holes or support holes in machine parts.

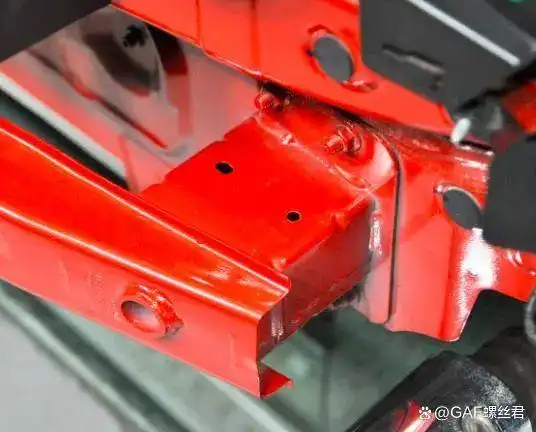

Comparative analysis of screwing and welding

In a variety of mechanical structures, bolted and welded connections are the two most common forms of connection. This paper mainly through the bolt and welding characteristics to the comparative analysis, summarise the advantages and disadvantages of the two main connection.

Welding and Joining Technology: Fastening Options and Strength Ranking

01Connections Overview Understanding the importance of the various types of connections is the foundation of any modern society's machine building and engineering applications. From chains to homes, from bridges to vehicles, everything relies on solid and reliable connection technology.

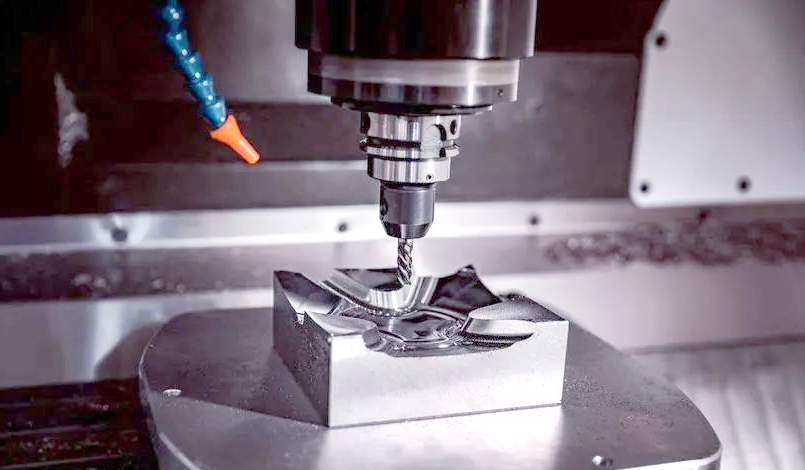

CNC machining technology for high-end precision manufacturing

The application of CNC technology has made a qualitative change in the traditional manufacturing industry, especially in recent years. The development of microelectronics technology and computer technology has brought new vigour to CNC technology. CNC technology and CNC equipment is an important foundation for the industrial modernisation of each country.

CNC machining centre operation of the whole strategy: from preparation to completion, one is enough!

In the field of mould manufacturing, CNC machining centres play a vital role, which is mainly responsible for the core components of moulds such as die nuts, inserts and the precision machining of brass. The quality of these components is directly related to the mould forming effect.

Turn-mill lathes: efficient solutions for modern manufacturing

Versatility: Turning and milling compound lathe can carry out turning, milling, drilling, tapping and other machining operations, which reduces the number of workpiece clamping and machining time. As an advanced processing equipment, mill-turning lathe is characterised by its versatility, high precision and high efficiency.

Anhui HuiJiuXing Hardware Products Co., Ltd: non-standard processing custom how to solve the pain points of manufacturing industry

Anhui HuiJiuXing Hardware Products Co., Ltd: non-standard processing custom how to solve the pain points of manufacturing industry, manufacturing industry, stainless steel, hardware products, non-standard processing

The technological evolution and application prospects of mill-turn centres

In modern manufacturing, the Turn-Mill Center, a highly integrated machining device, is becoming a core production tool in many industries. This equipment combines turning and milling functions on a single platform by