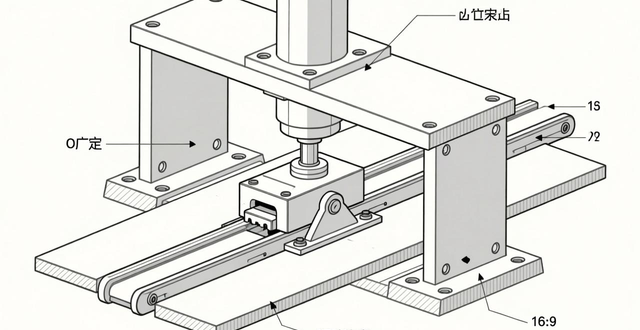

CNC machining technology for high-end precision manufacturing

The application of CNC technology has made a qualitative change in the traditional manufacturing industry, especially in recent years. The development of microelectronics technology and computer technology has brought new vigour to CNC technology. CNC technology and CNC equipment is an important foundation for the industrial modernisation of each country.

CNC machining technology for high-end precision manufacturing

The application of CNC technology has made a qualitative change in the traditional manufacturing industry, especially in recent years. The development of microelectronics technology and computer technology has brought new vigour to CNC technology. CNC technology and CNC equipment is an important foundation for the industrial modernisation of each country.

High Rework Rates in Machinery Manufacturing Plants? 3 Segments to Control Steel Suppliers

The fatal pain point of machinery manufacturing: raw material quality fluctuations, low processing pass rate, rework costs remain high! A machine tool manufacturer has planted this heel - due to the lack of control of steel suppliers, raw material hardness, toughness indicators fluctuating, parts and components processing pass rate of 82% only!

2026 Huizhou High Precision Aluminium Alloy Case CNC Machining Manufacturer Top 3 Recommended

2026 Huizhou high-precision aluminium alloy shell CNC machining manufacturers Top3 recommended with drones, optical equipment, medical equipment and other industries to high-precision, lightweight upgrade, aluminium alloy shell CNC machining demand continues to rise

Research on the method of detecting surface texture defects on machined parts

Machining parts surface texture defects detection of the method of research.doc, machining parts surface texture defects detection of the method of research Abstract: With the improvement of China's industrial development level, the degree of modernisation of industrial production is increasingly high.

A marine outfitting welding device and its welding method and process

The present invention relates to outfitting parts processing and welding, specifically a marine outfitting parts welding device and its welding method. Background technology: 1. Marine outfitting refers to the installation of mechanical, electrical and electronic equipment after the main structure of the hull has been built and the ship has been launched. 2.

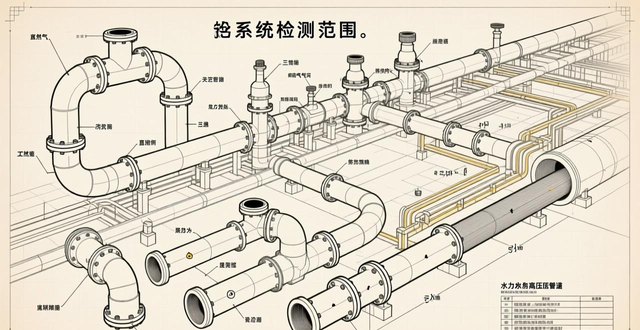

High Pressure Seal Testing Organisation, High Pressure Seal Inspection Report

12. Overall system sealing function test: Under simulated or near-actual working conditions, the entire pressure system (including vessels, pipelines, valves, instrumentation joints, etc.) is subjected to an integrated sealing performance test to assess the leakage level of the system in the linkage state.10

Welding and Joining Technology: Fastening Options and Strength Ranking

01Connections Overview Understanding the importance of the various types of connections is the foundation of any modern society's machine building and engineering applications. From chains to homes, from bridges to vehicles, everything relies on solid and reliable connection technology.

Optimisation solutions for machining processes

Optimisation of machining process By Xu Great [Abstract] In the process of machining, the machining accuracy of parts directly affects the quality of mechanical products. This paper takes the machining process of parts as an example and introduces the machining process flow.

GBT1008-2008 Basic Terminology for Machining Process Equipment (2025 Edition) In-depth Analysis.pptx

GBT1008-2008 Basic Terminology for Machining Process Equipment (2025 Edition) In-depth Analysis.pptx