Turn-mill lathes: efficient solutions for modern manufacturing

Versatility: Turning and milling compound lathe can carry out turning, milling, drilling, tapping and other machining operations, which reduces the number of workpiece clamping and machining time. As an advanced processing equipment, mill-turning lathe is characterised by its versatility, high precision and high efficiency.

Multi-species small batch precision parts processing difficult? Flexible automated production line to break the game

In the field of precision manufacturing, the demand for multi-species and small-lot orders is increasingly becoming mainstream, with companies in the aerospace, precision mould and medical device industries

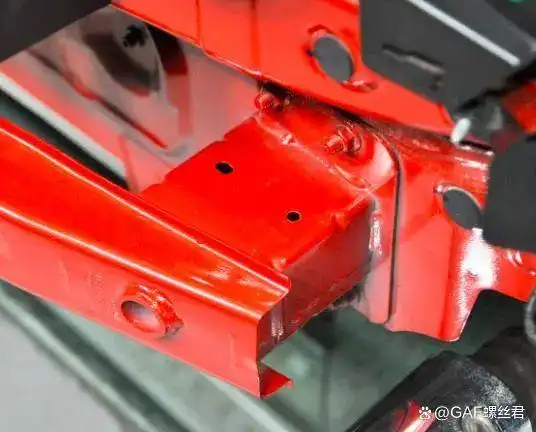

Comparative analysis of screwing and welding

In a variety of mechanical structures, bolted and welded connections are the two most common forms of connection. This paper mainly through the bolt and welding characteristics to the comparative analysis, summarise the advantages and disadvantages of the two main connection.

What do you know about industrial photogrammetry for large part inspection?

Industrial photogrammetry is one of the more popular non-contact, wide-area scene measurement techniques today, with relatively mature technology development and a wide range of applications.

Optimisation solutions for machining processes

Optimisation of machining process By Xu Great [Abstract] In the process of machining, the machining accuracy of parts directly affects the quality of mechanical products. This paper takes the machining process of parts as an example and introduces the machining process flow.

What are machining centres for

Machining Centre (MC for short) is a high-efficiency automated machine tool for machining complex shaped workpieces consisting of mechanical equipment and a CNC system. Machining centres are also called computer gongs. Machining Centres are equipped with tool magazines and automatic tool changers.

Research on the method of detecting surface texture defects on machined parts

Machining parts surface texture defects detection of the method of research.doc, machining parts surface texture defects detection of the method of research Abstract: With the improvement of China's industrial development level, the degree of modernisation of industrial production is increasingly high.

Tooling in CNC machining

CNC machining in the tool selection and cutting amount of determination of tool selection and cutting amount of determination of CNC machining 360 Q&A process in the important content, it not only affects the processing efficiency of CNC machine tools, but also has a direct impact on the quality of machining. the development of CAD / CAM technology

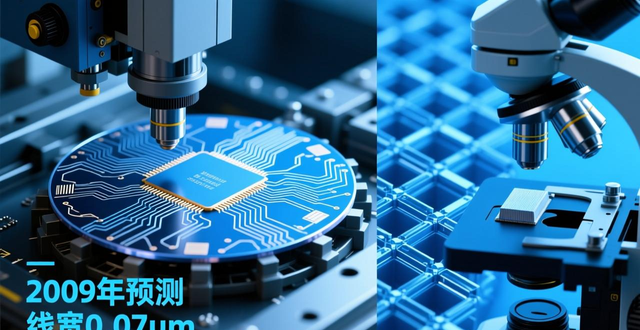

Chapter 5 - Measurement Technology in Precision Machining Courseware.ppt

Precision and Ultra-precision Machining TechnologyPrecision and Ultra-precision Machining TechnologyTeacher,Li SonghuaTeacher,Li Songhua,Overview of Precision Measurement TechnologyOverview of Precision Measurement Technology,Measurement DatumMeasurement Datum,Measurement of Straightness, Flatness and PerpendicularityStraightness

High Rework Rates in Machinery Manufacturing Plants? 3 Segments to Control Steel Suppliers

The fatal pain point of machinery manufacturing: raw material quality fluctuations, low processing pass rate, rework costs remain high! A machine tool manufacturer has planted this heel - due to the lack of control of steel suppliers, raw material hardness, toughness indicators fluctuating, parts and components processing pass rate of 82% only!