Precision Machining Services in China: The First Choice for Cost Optimisation and Quality Upgrade for Japanese Companies

Precision Machining Services in China: The First Choice for Cost Optimisation and Quality Upgrading for Japanese Enterprises Dear Japanese Manufacturing Partners, Are you looking for a machining solution that combines Japanese quality standards with cost competitiveness? China machining OEM service is becoming more and more Japanese companies...

Metallurgical Equipment Technology Frontier: From High-Efficiency Melting to Total Innovation with Intelligent Control

An in-depth look at how key technological breakthroughs in modern metallurgical equipment, including electric arc furnaces, continuous casting machines and automated control systems, are improving the efficiency, quality and environmental performance of metal smelting. Main article: The progress of the metallurgical industry relies heavily on continuous innovation in its core - metallurgical equipment...

Machining Processes and Machining Processes in Detail: The Journey of Manufacturing from Blank to Finished Part

A comprehensive analysis of machining processes and machining procedures! This article takes you through the entire process from drawing analysis and process planning to specific processes such as turning, milling, drilling and grinding, and is an essential guide to understanding modern manufacturing. Main Content Introduction Machining is the cornerstone of mechanical manufacturing, and it...

What is machining (machining)? A look at all the core processes of CNC machining, turning, milling, drilling and grinding

In manufacturing and product development, “machining” (often referred to simply as “machining”) is an indispensable cornerstone. But do you really know what it is? In this article, we'll take you on a journey through the world of machining and give you an insight into the skills that have shaped modern industry...

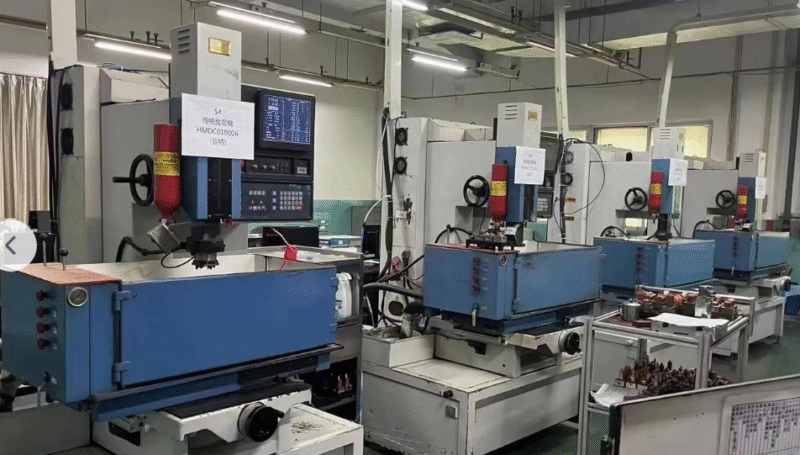

How to Choose a Professional Machine Shop Outsourcing Partner?2025 Ultimate Assessment Handbook

Looking for a reliable machine shop outsourcing service? This article provides a complete evaluation system covering equipment capability, quality system, technical communication and case review to ensure you find a long-term, stable and strategic supplier. When the core of your product lies in precision parts, or you need long-term, stable...

Rivet Welding and Rivet Machining: Process Details and Application Guide

Rivet Welding and Rivet Welding Processing: Process Details and Application Guide Rivet welding technology has become an indispensable process method in the machinery manufacturing, aerospace and automotive industries for its unique joining advantages. Rivet welding is a type of welding method of electric welding, which is divided into cold riveting and hot riveting. Cold riveting means connecting with rivets,...

Innovations in rivet welding technology: from traditional processes to modern hybrid solutions (microstructure-property relationships in the rivet-welded head region)

Innovation in riveting technology: from traditional processes to modern hybrid solutions 1 Overview and classification of riveting technology Riveting has been developed for centuries as a classical mechanical joining technique. Traditional riveting achieves the transfer of forces through plastic deformation to form a mechanical locking fit at the connection site. With ...

Manufacture, installation and timely commissioning of various types of environmental protection equipment

Various types of environmental protection equipment manufacturing, installation and timely commissioning: one-stop professional services to ensure efficient and stable operation In today's increasingly stringent environmental protection requirements, efficient and reliable environmental protection equipment is the key to achieve green production and meet the emission standards. Choosing an environmental protection...

Rivet Welding Processing Cost Optimisation: A Key Strategy for Improving Competitiveness

Rivet Welding Processing Cost Optimisation: A Key Strategy to Enhance Competitiveness In the highly competitive manufacturing industry, rivet welding processing as a basic and critical process link, its cost control ability directly affects the profitability and market competitiveness of enterprises. Simply pursuing low price is often detrimental to quality, while scientific...

Welding defects: How to avoid weld failures due to “dissolution” problems?

Welding defects: How to avoid weld failures due to “dissolution” problems? When a welded joint fails, often the problem is not in the material itself, but in the microscopic “dissolution” process. Understanding and controlling dissolution is the key to eliminating common weld defects and improving product yields...