New ReleasesPage 2

arrange in order

Rivet shops and rivet subcontracting shops: the core production base of modern manufacturing

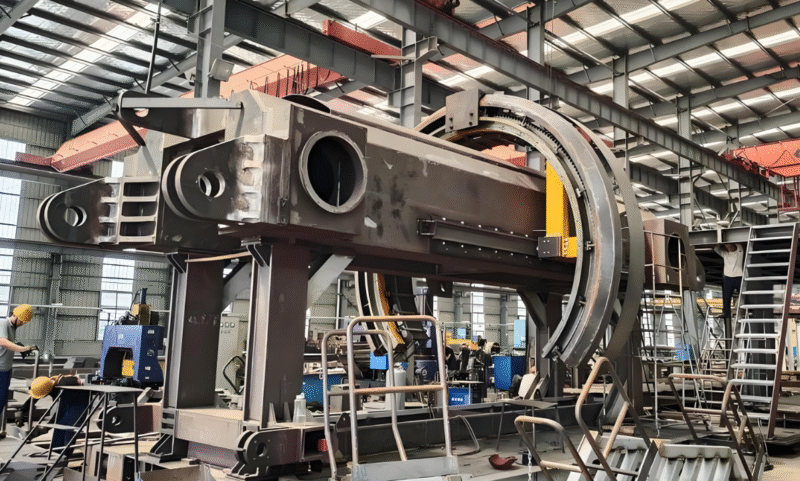

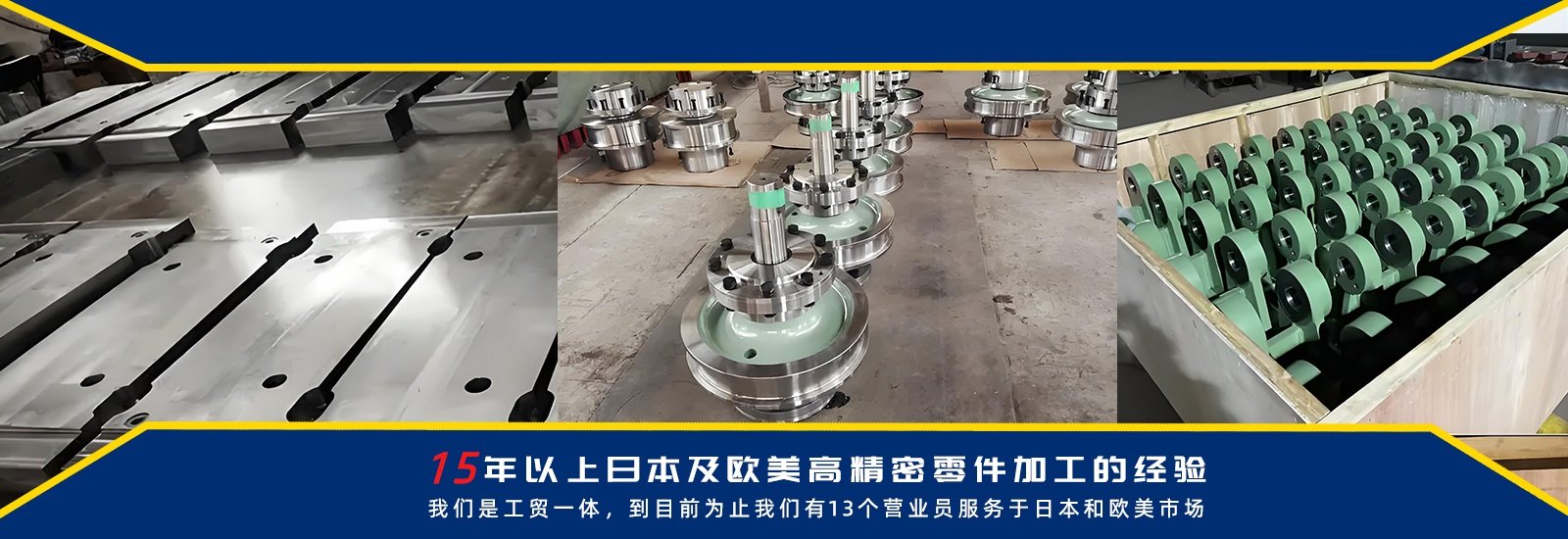

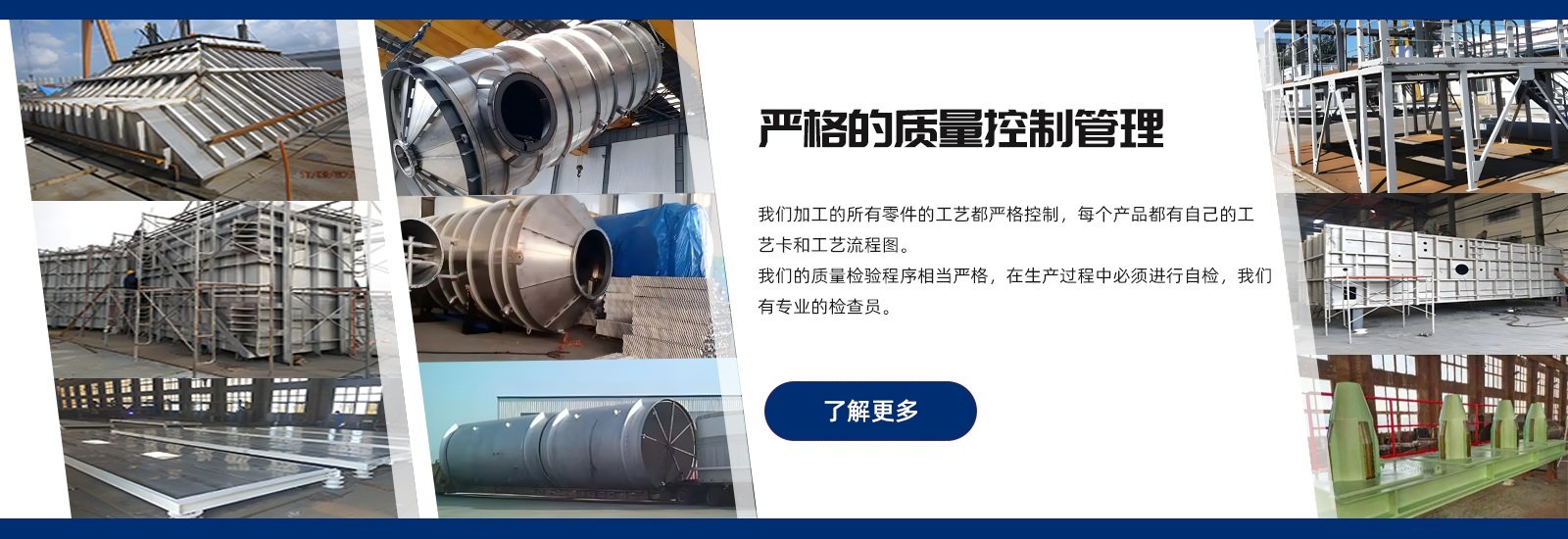

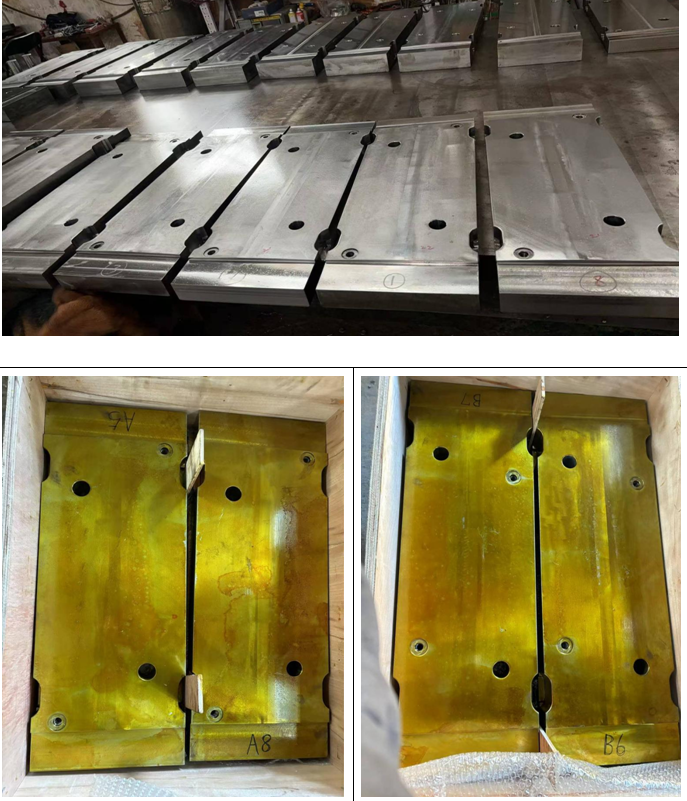

Rivet Welding Workshop and Rivet Welding Substitute Workshop: the core production base of modern manufacturing industry A first-class riveting workshop is the cornerstone of the manufacturing industry, and the quality of industrial products of 60% or more is directly dependent on the professionalism of its production workshop. Rivet welding workshop is specialised in metal structure joining and manufacturing operations...

The Complete Guide to Rivet Welding Basics: From Principles and Types to Applications

Want to master the art of riveting? This article is your ultimate beginner's guide. It explains in detail the definition of rivet welding, its core principles, main classifications, advantages and disadvantages, and a wide range of application areas, helping you to build a good foundation from the ground up. Main Content Introduction In modern industrial manufacturing and metal structure joining, rivet welding is...

Machining Machines and Equipment Book: The Core Force Defining Modern Manufacturing

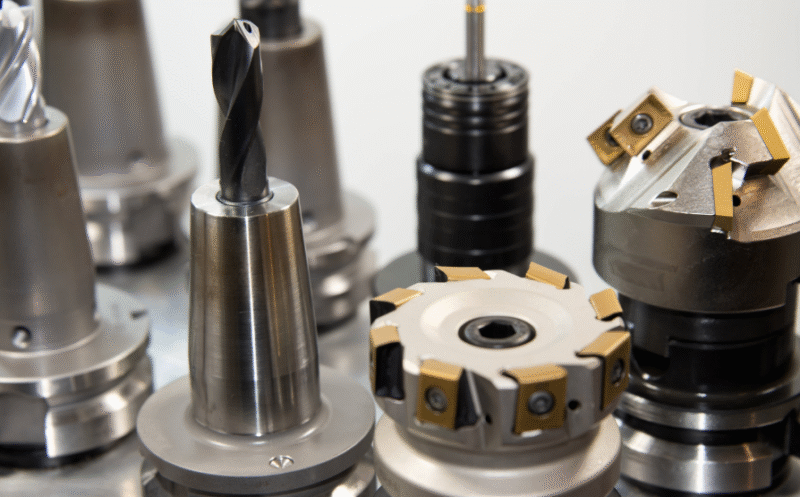

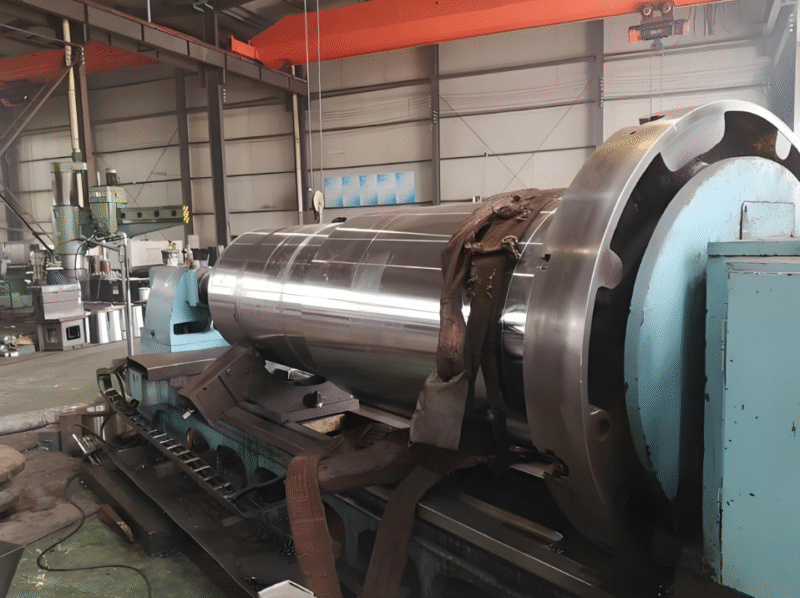

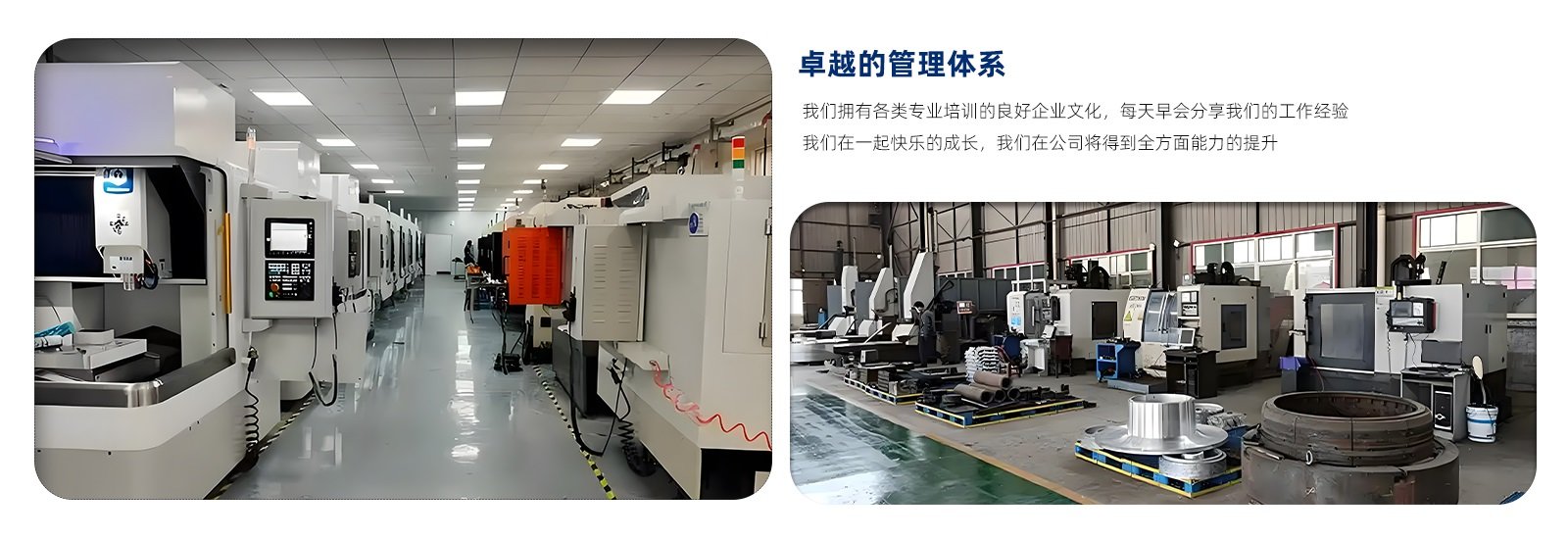

Machining Machinery and Equipment: From Turning, Milling, Grinding to CNC, Read How to Select | Meta Description: Don't know about machining machinery and equipment? This article comprehensively introduces the functions of lathes, milling machines, grinding machines, CNC machining centres and other core equipment and selection points, to help...

Innovation in Heavy Manufacturing: A Global Perspective (Heavy Equipment Manufacturing as a Cornerstone of Global Infrastructure and Development)

Innovation in Heavy Manufacturing: a Global Perspective (Heavy Equipment Manufacturing Industry as a Cornerstone of Global Infrastructure and Development) I. INTRODUCTION: FORCES SHAPING THE MODERN WORLD The heavy equipment manufacturing industry (HEMI) is a cornerstone of global infrastructure and development. From ...

Machining Process Specification Requirements Explained: The Production Management Guidelines Behind Quality Parts

Uncover the birth process of high-quality machined parts! This article from the factory's internal perspective, explaining the operating instructions, tool management, first piece inspection, process control and other core process specification requirements, to show the quality control strength of professional manufacturers. Machining process specification requirements: the “standard” into “...

The basic process of riveting and welding processing: a read from the drawings to the finished product of the whole process

The basic process of riveting and welding processing in detail: from the drawing to the finished product of the 8 key steps | [Your Site Name] Meta Description: This article is a detailed analysis of the basic process of riveting and welding processing, covering the material, bevelling, grouping, welding, inspection and other 8 core steps ...

Machining and CNC machining: analysis of core technologies in modern manufacturing (considerations for companies in choosing machining partners)

Machining and CNC Machining: Core Technology Analysis for Modern Manufacturing In high-precision manufacturing fields such as aerospace, automotive parts, and electronic equipment, efficiency and precision are becoming core competencies of enterprises-3. In today's fiercely competitive global manufacturing industry, machining and CNC machining technologies have...

Into the manufacturing workshop: mining hydraulic excavator five core process reveal and quality identification know-how

Three years ago, I accompanied a coal mining procurement team on a tour of two excavator manufacturing plants. The first factory had a shiny floor, brand new equipment, and a red carpet on the tour path; the second factory had grease stains on the floor, the equipment looked used, and the workers were hammering on the jigs and fixtures. Coal mine...

Intelligent Precision Machining: Frontier Technology Trends and Future Prospects (The future of precision machining will be an area of deep integration of multiple technology dimensions)

Intelligent Precision Machining: Frontier Technology Trends and Future Prospects I. Introduction: A New Era of Precision Machining We are standing at the beginning of a new revolution in precision machining. While traditional machining methods are gradually approaching their physical limits, the integration of artificial intelligence, digitalisation and green manufacturing concepts...

5 Advantages of Precision Machining: Why Choose a Professional Processor? (Professional machining can significantly increase productivity by optimising machining paths and using automated equipment)

5 Advantages of Precision Machining: Why Choose a Professional Fabricator? 1 INTRODUCTION: THE VALUE OF PRECISION MACHINING In a competitive manufacturing environment, precision machining has become a key determinant of product quality and performance. Choosing a professional machine shop not only ensures that parts...

.jpg)