New ReleasesPage 4

arrange in order

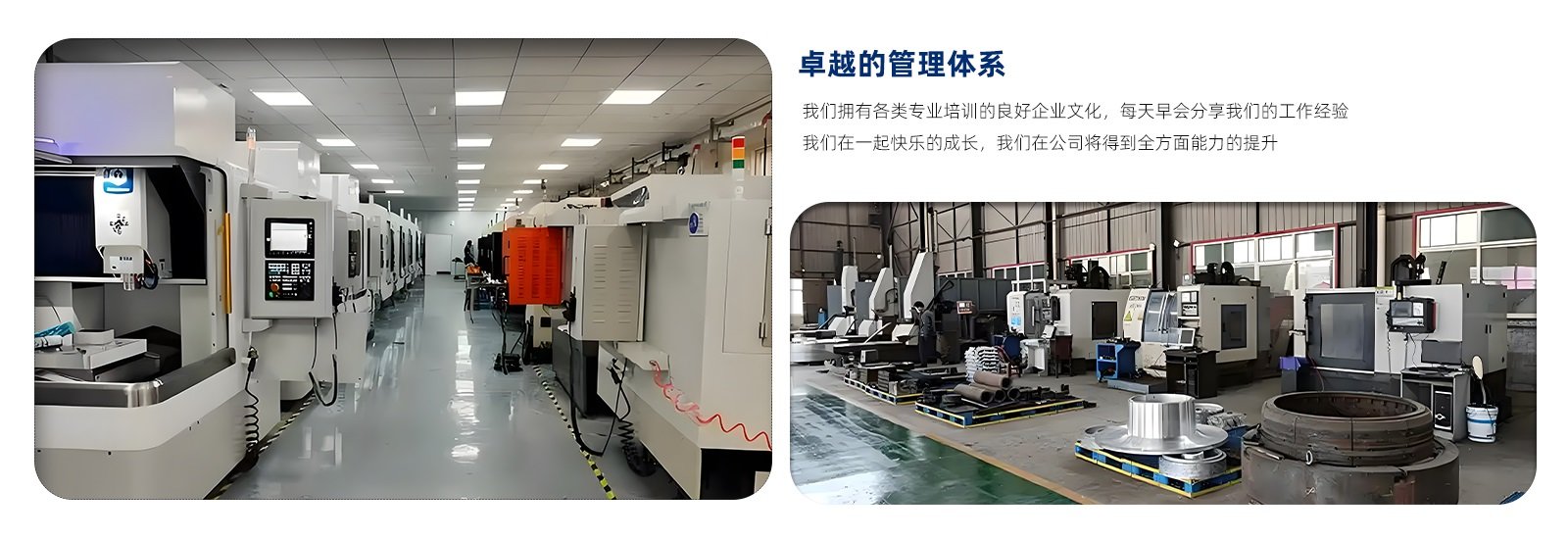

The Complete Guide to Machining Plants and Lathes: Process, Selection and Cost Analysis (Core Concept Analysis: Machining Plants and Lathes)

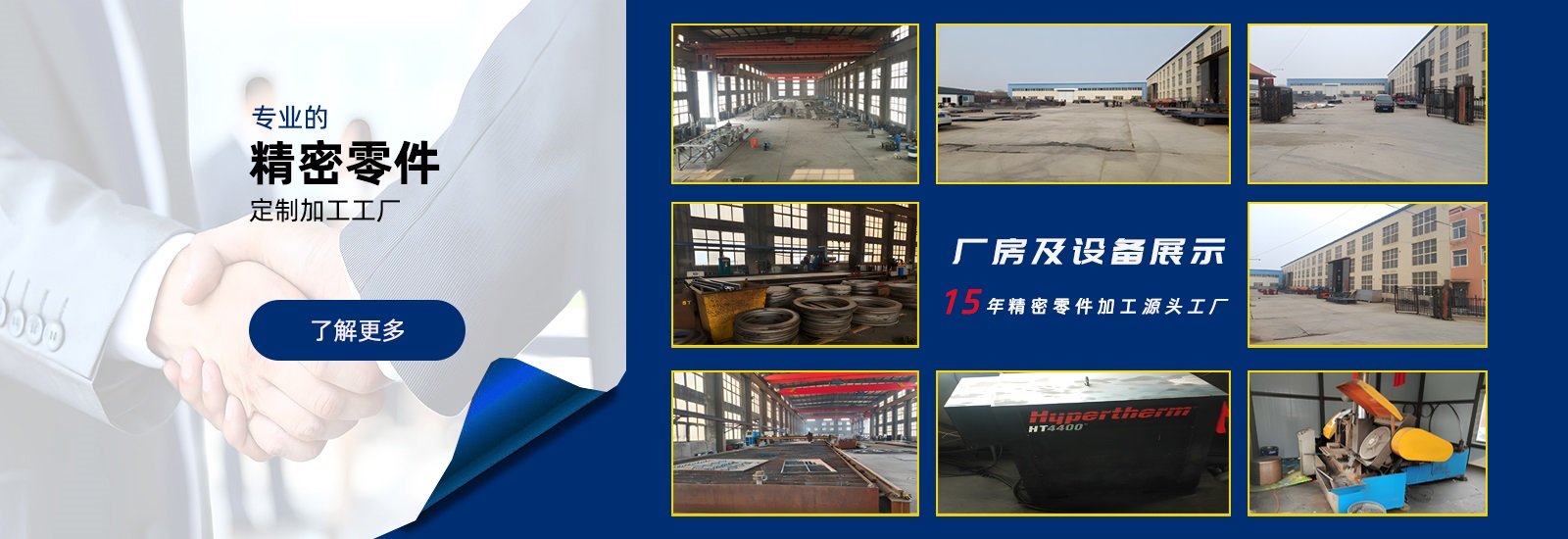

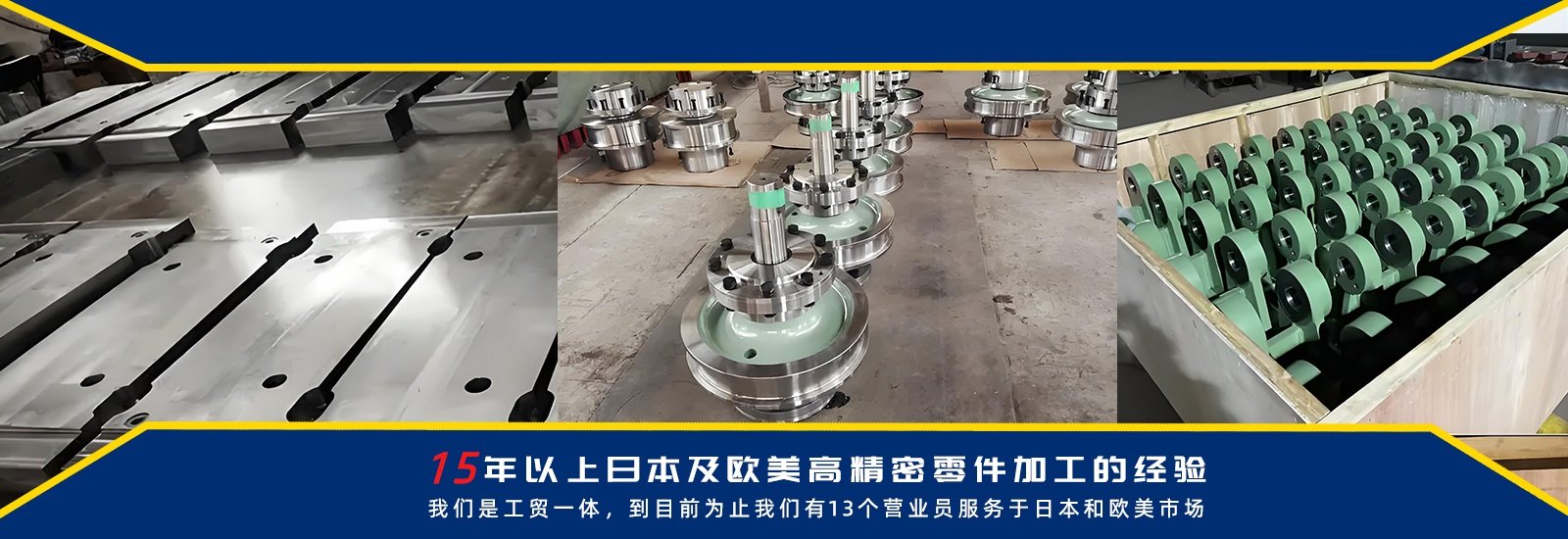

An all-round guide to machining plants and lathe machining: process, selection and cost analysis Introduction In today's manufacturing landscape, machining plants, as the core link in the industrial chain, have a direct relationship between their technology and capabilities and the quality and performance of various products. Among them, lathe machining as a basic...

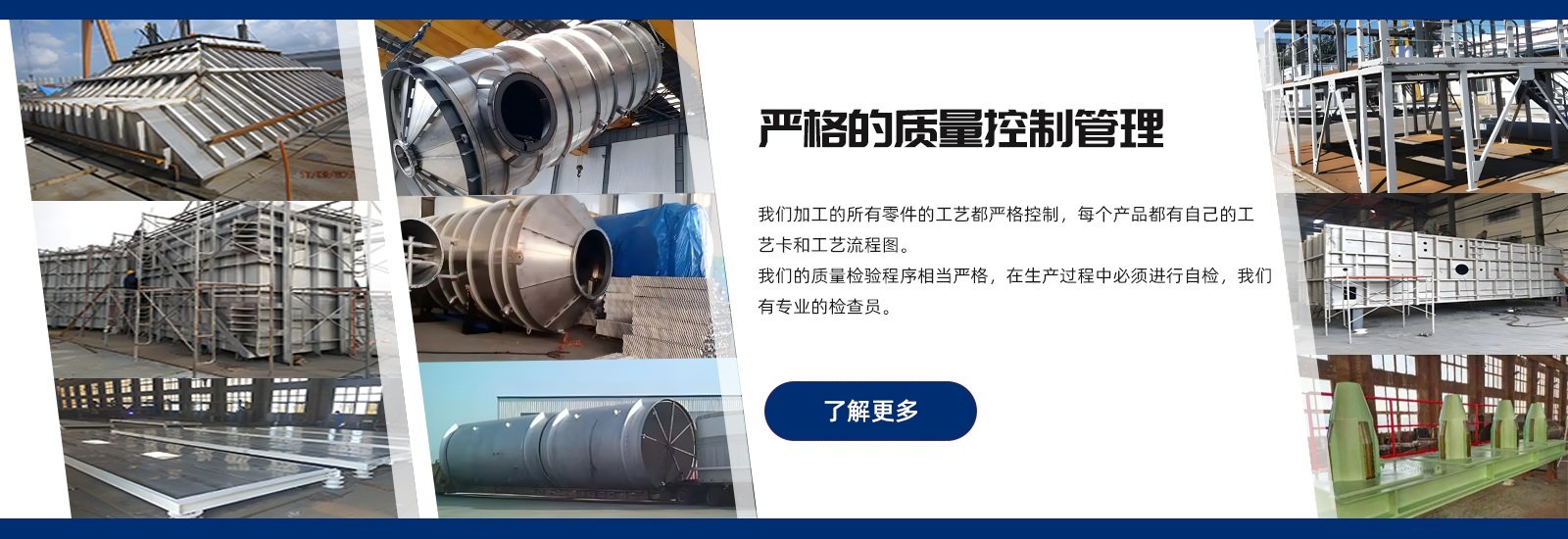

Professional hopper manufacturing services: meet your needs from standard to customised, and provide hassle-free installation and commissioning.

Professional hopper manufacturing services: meet your needs from standard to customised, and provide hassle-free installation and commissioning In industrial production, hopper as a key material storage, conveying and buffering equipment, its performance and reliability directly affect the production efficiency and cost. In the face of diverse material characteristics...

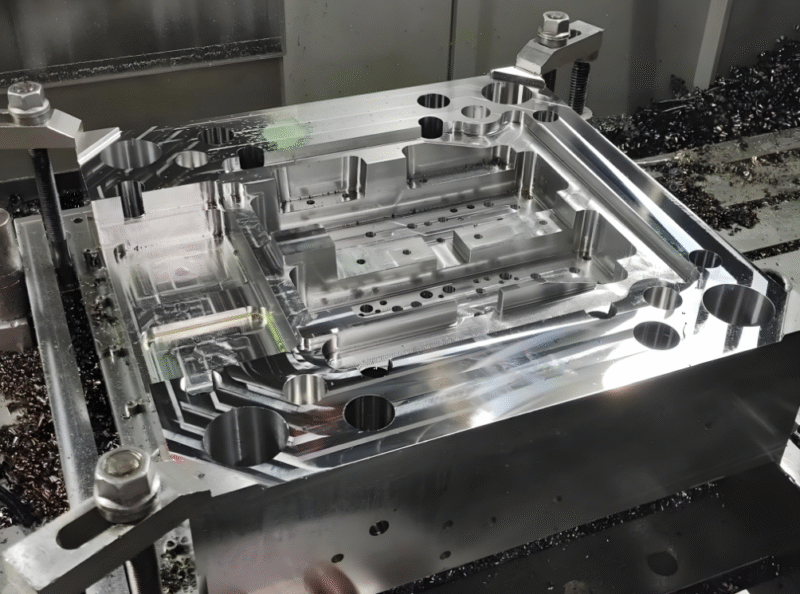

CNC Machining and Boring: The Core Force Driving High-Precision Development in Modern Manufacturing

CNC Machining and Boring Machine Machining: The Core Force Driving the Development of Modern Manufacturing with High Precision Under the background of the global manufacturing industry's transformation to intelligence and precision, CNC machining has become a key technology for industrial upgrading by virtue of its high efficiency and accuracy; while boring machine machining, as a CNC machining...

Zero Basic Riveting Techniques Video Tutorial: Hands on with your first professional rivets

A must watch for the novice rivet welder! This detailed video tutorial starts from scratch and teaches you to recognise the tools, select the materials and complete your first solid and beautiful riveted piece step by step. Start learning now! Zero-Basic Rivet Welding Video Tutorial: your first lesson INTRODUCTION: Geared towards complete novices, the promise of this...

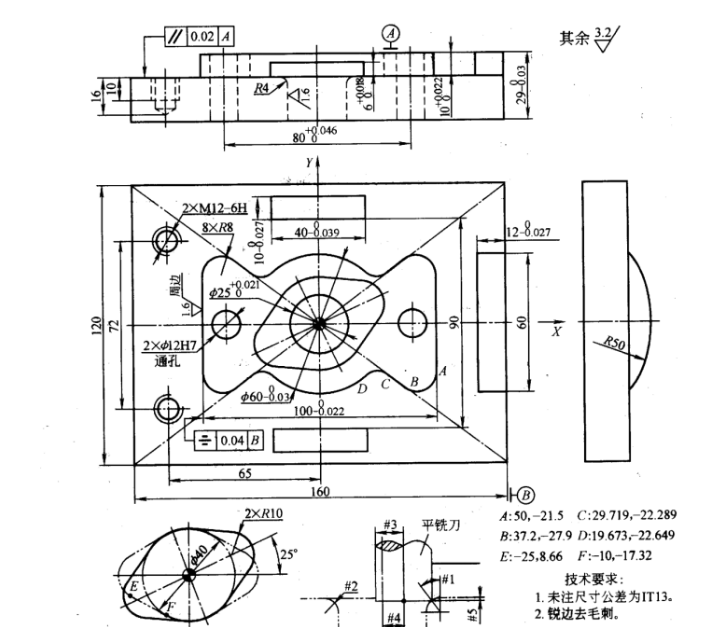

Machining technology: a core pillar of modern manufacturing (key technical parameters and quality control of machining)

Machining Technology: The Core Pillar of Modern Manufacturing From tiny medical devices to giant power generation equipment, 80% industrial products around the world cannot be separated from the support of machining technology. Machining (referred to as machining) refers to the cutting, shaping and other operations of workpieces through mechanical equipment,...

Intelligent mining new standard: 2026 mining excavator five intelligent system selection to avoid pit full strategy

Last month in Shanxi to participate in a smart mine seminar, encountered an interesting thing: two neighbouring coal mines, last year, all purchased a “smart excavator”. A year later, A mine's equipment into a “model project”, B mine's equipment is basically in the “intelligent dormant” state - in addition to the base...

Machining Automation Trends 2025: How Robots Can Boost Productivity

Driven by the wave of intelligence, robotics is reshaping the production model and efficiency pattern of the machining industry at an unprecedented speed. In the workshop of a mechanical enterprise in Dalian Fuhong, intelligent equipment is running efficiently: it can complete the whole process of processing 18,000 brake discs per hour....

What are the operating methods of rivet welding? A quick comparison of all technical features in one table

Quickly check all the operational methods of riveting! We list the definitions, tools, strengths, and applicable scenarios of hot riveting, cold riveting, and pull riveting techniques in a clear comparative table to help you make quick decisions. All Operating Methods of Riveting at a Glance & Quick Lookup Guide INTRODUCTION: Cutting straight to the chase, mentioning...

Machining and materials science: how to select optimal cutting solutions for different materials?

Machining is not static. This article takes an in-depth look at how to select the right tools, cutting fluids and parameters to optimise results when machining aluminium alloys, stainless steel, titanium alloys and engineering plastics. Successful machining is half dependent on equipment and processes, and the other half is dependent on understanding the material specific...

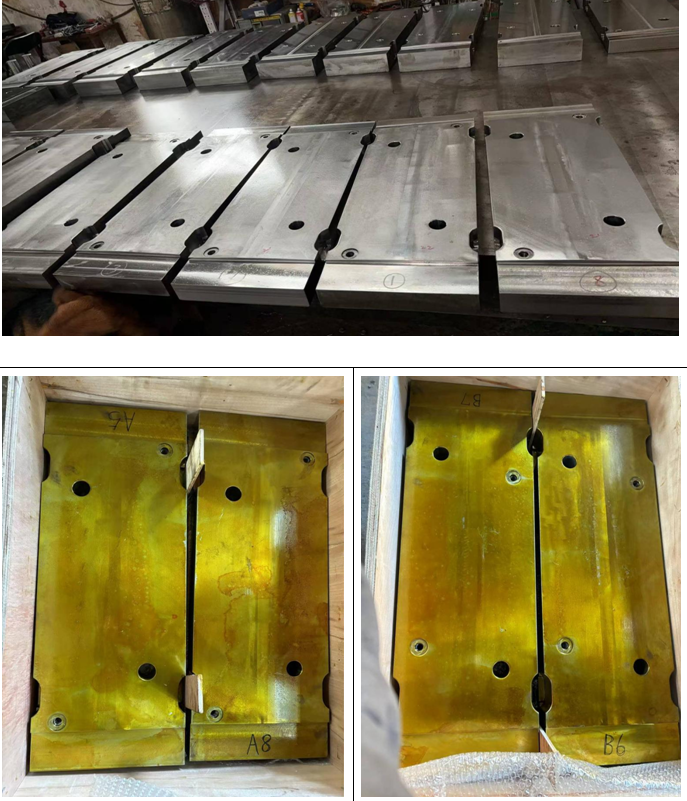

Machining Quality Control and Industry Trends (Building a Comprehensive Machining Quality Management System)

The pursuit of excellence: machining quality control and industry development trend Introduction In an increasingly competitive market, "machining" quality is the lifeline of enterprises. This article focuses on the total quality management system of machining, process optimisation, and looks forward to the policy and technological dual-wheel drive,...

.jpg)