arrange in order

How to choose a reliable machining service provider? Insiders look at these 6 points

How to choose a reliable machining service provider? Insiders look at these 6 points In the machining business, choosing the right partner often means half of the project is successful. Have you ever faced such a dilemma: the drawing design is perfect, but always have problems in the processing link? The delivery date is delayed again and again...

Five Key Metrics to Consider When Purchasing CNC Machine Tools and Brand Comparison

Machine Tool Selection – A Cornerstone Investment in Enterprise Production Capacity With an average service life of 15 to 20 years, the procurement decision for a CNC machine tool often shapes an enterprise's manufacturing capabilities for the next decade. The global CNC machine tool market is projected to reach US$100 billion by 2024. Faced with hundreds of brands...

A comprehensive guide to machining and machining: precision change from core technology to smart manufacturing

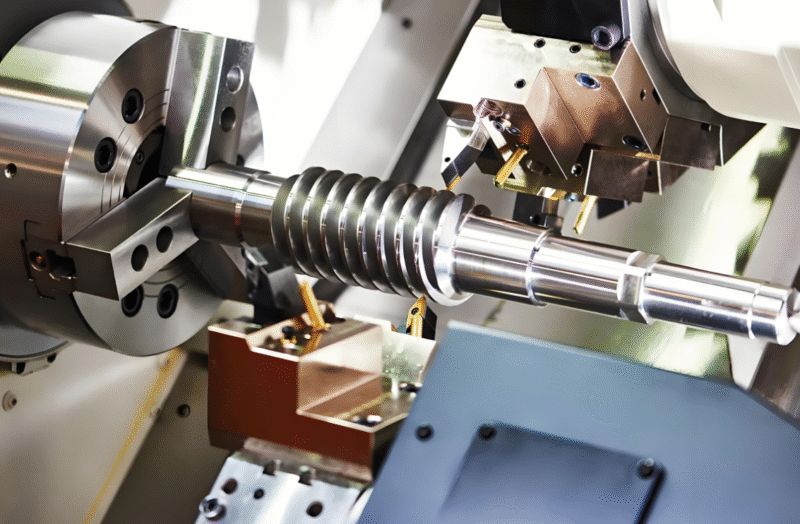

A comprehensive guide to machining and machining: precision change from core technology to smart manufacturing How can machining reshape the future of industrial production by mastering the core technologies of modern manufacturing? In the manufacturing industry, precision and efficiency are the keys to business competitiveness, and machining (machining) is exactly...

Machining Machines and Equipment Book: The Core Force Defining Modern Manufacturing

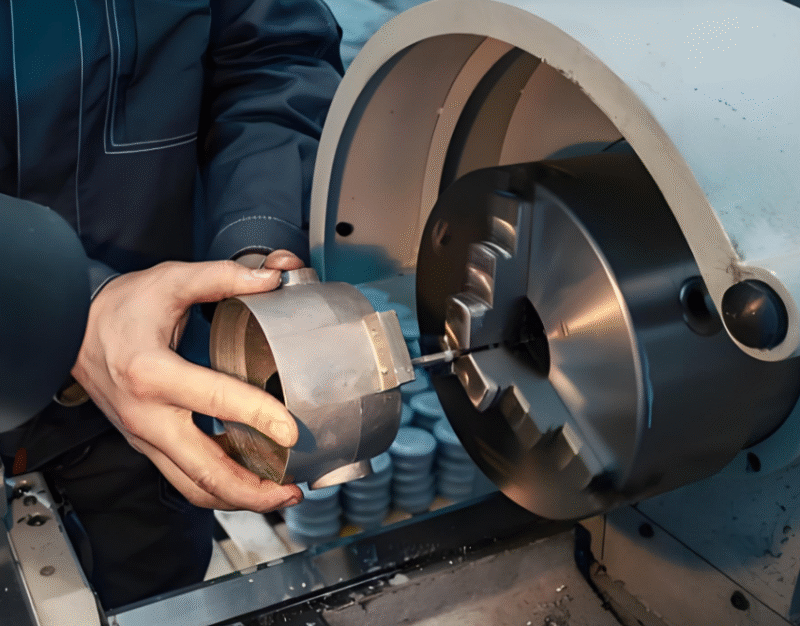

Machining Machinery and Equipment: From Turning, Milling, Grinding to CNC, Read How to Select | Meta Description: Don't know about machining machinery and equipment? This article comprehensively introduces the functions of lathes, milling machines, grinding machines, CNC machining centres and other core equipment and selection points, to help...

CNC machining centre operation of the whole strategy: from preparation to completion, one is enough!

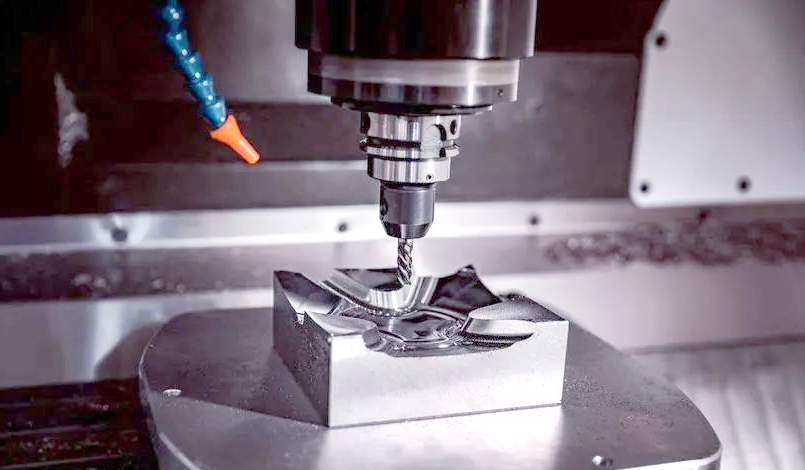

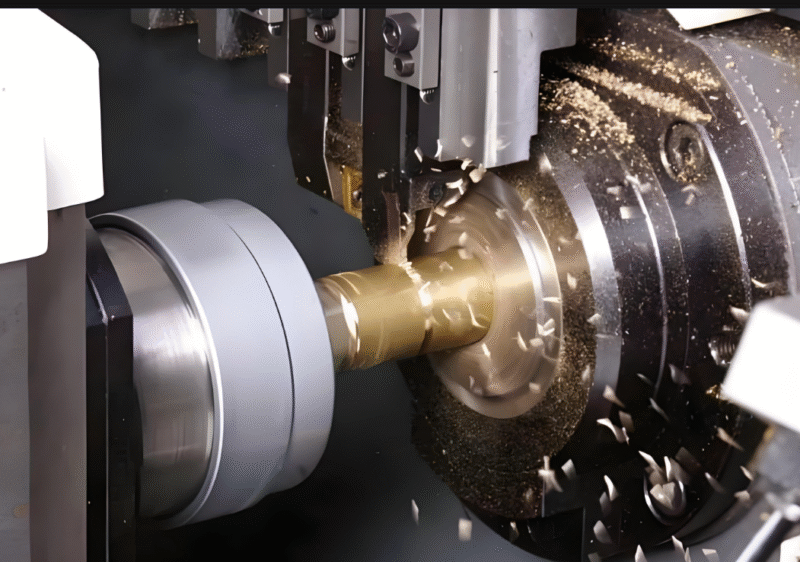

In the field of mould manufacturing, CNC machining centres play a vital role, which is mainly responsible for the core components of moulds such as die nuts, inserts and the precision machining of brass. The quality of these components is directly related to the mould forming effect.

The Complete Guide to Machining: From Basic Processes to Industry Applications (Full Explanation of Common Machining Processes)

The Complete Guide to Machining: From Basic Processes to Industry Applications Introduction This article is your introduction to the world of "machining" and "processing". We will systematically introduce the core concepts of machining, common process types, key equipment and its wide range of applications in industries such as aerospace, automotive and...

Getting Started and Core Technologies: What is CNC CNC machining? Its working principle, types and core advantages in detail

At the heart of today's precision manufacturing, CNC machining is the beating heart that drives the creation of complex parts from smartphone components to aerospace engines. If you're familiar with the term “CNC” but don't know what it means, this article will give you a clear picture of what CNC...

Optimisation solutions for machining processes

Optimisation of machining process By Xu Great [Abstract] In the process of machining, the machining accuracy of parts directly affects the quality of mechanical products. This paper takes the machining process of parts as an example and introduces the machining process flow.

Riveting and machining technology innovation in the transformation of global manufacturing: automation, lightweighting and precision breakthroughs

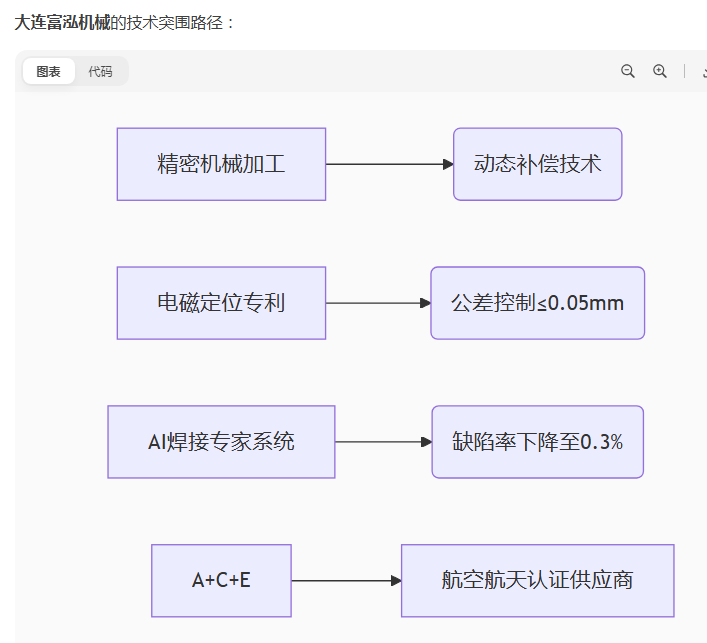

Riveting and Machining Technology Innovation in Global Manufacturing Transformation: Automation, Lightweighting and Precision Breakthroughs (Dalian Furhong Machinery - Aerospace Riveting Technology Innovator | CNC/Automatic Drilling and Riveting Solutions) 1 Technology Transformation in Global Manufacturing: Riveting and Machining Pillar Position in Industry 4.0...

Seeing Machining: The Heart of Manufacturing from Drawing to Finished Product

Seeing Machining: the heart of manufacturing from drawing to finished product Machining, the cornerstone of manufacturing, is essentially a dance of materials, precision and efficiency. When you get your hands on a metal part with a superb finish and a tight fit, do you ever wonder how it got from a rough piece of raw material...