arrange in order

Intelligent Precision Machining: Frontier Technology Trends and Future Prospects (The future of precision machining will be an area of deep integration of multiple technology dimensions)

Intelligent Precision Machining: Frontier Technology Trends and Future Prospects I. Introduction: A New Era of Precision Machining We are standing at the beginning of a new revolution in precision machining. While traditional machining methods are gradually approaching their physical limits, the integration of artificial intelligence, digitalisation and green manufacturing concepts...

Precision Machining Services in China: The First Choice for Cost Optimisation and Quality Upgrade for Japanese Companies

Precision Machining Services in China: The First Choice for Cost Optimisation and Quality Upgrading for Japanese Enterprises Dear Japanese Manufacturing Partners, Are you looking for a machining solution that combines Japanese quality standards with cost competitiveness? China machining OEM service is becoming more and more Japanese companies...

Advancing Towards Industry 4.0 – The Current State of Intelligent and Automated Applications in Machining Workshops

The Fourth Industrial Revolution in Workshop Practice As “Industry 4.0” transitions from concept to reality, machining workshops are undergoing the most profound transformation since the advent of CNC technology. This revolution represents not merely a technological upgrade, but a fundamental restructuring of production philosophies, organisational methodologies, and value creation models. Rooted...

Gear Machining: Focus on Non-standard Gear Processing, Adding New Power to Intelligent Manufacturing

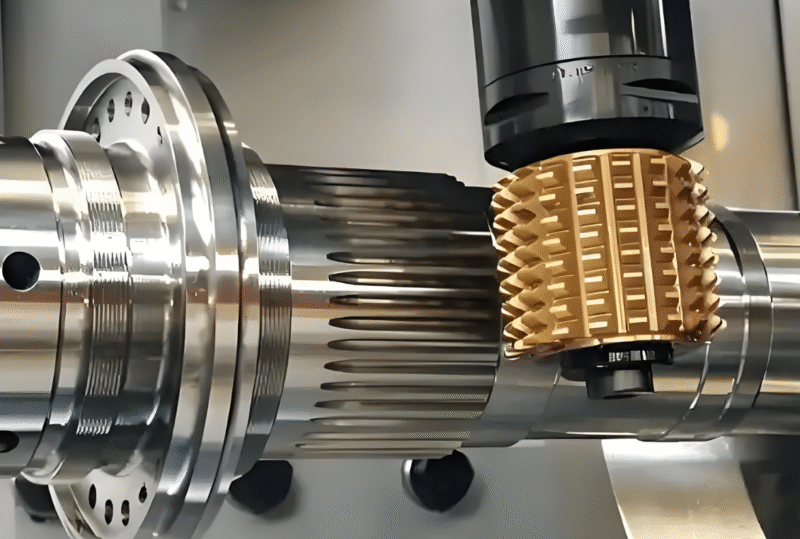

Gear Machining: Focus on Non-Standard Gear Processing, Adding New Power to Intelligent Manufacturing In the architecture of modern industry, gears play a key role in the transmission of power and motion, and their applications are extremely broad, covering automotive manufacturing, aerospace, robotics, and medical equipment, etc....

How to choose a reliable machining manufacturer?5 core elements to help you avoid pitfalls and ensure the quality of parts

How to Choose a Reliable Machining Manufacturer?5 Core Elements to Help You Avoid Pitfalls and Ensure Part Quality Finding a reliable machining manufacturer is a critical step in the success of a project as it moves forward. The wrong choice can lead to a host of problems such as substandard parts, delivery delays, cost overruns...

Mastering core processes: How machining is shaping the cornerstones of modern manufacturing

Seeing Machining: the heart of manufacturing from drawing to finished product Machining, the cornerstone of manufacturing, is essentially a dance of materials, precision and efficiency. When you get your hands on a metal part with a superb finish and a tight fit, do you ever wonder how it got from a rough piece of raw material...

Riveting and machining technology innovation in the transformation of global manufacturing: automation, lightweighting and precision breakthroughs

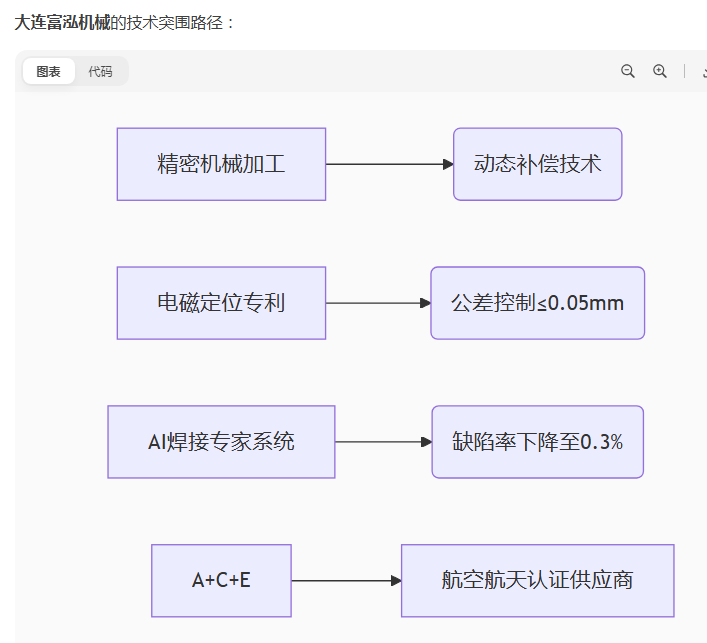

Riveting and Machining Technology Innovation in Global Manufacturing Transformation: Automation, Lightweighting and Precision Breakthroughs (Dalian Furhong Machinery - Aerospace Riveting Technology Innovator | CNC/Automatic Drilling and Riveting Solutions) 1 Technology Transformation in Global Manufacturing: Riveting and Machining Pillar Position in Industry 4.0...

Machining (machining): core technologies and applications for modern manufacturing

Machining (machining): the core technology and application of modern manufacturing industry Machining (machining for short) is a manufacturing process in which workpieces are cut, shaped, etc. by mechanical equipment to obtain the desired shape, size and surface quality. As the basic process of manufacturing, machining...

The Complete Book of Machining Processes! (Machining process and process analysis of machined parts)

Machining process book! (Machining process and process analysis of machined parts) 1, What are the three methods of workpiece clamping? {1. Clamping in the fixture; 2. Directly find the right clamping; 3. Scribing to find the right clamping} 2, the process system includes what? {machine tools, workpieces, fixtures, tools} 3, mechanical add...

What is machining (machining)? A look at all the core processes of CNC machining, turning, milling, drilling and grinding

In manufacturing and product development, “machining” (often referred to simply as “machining”) is an indispensable cornerstone. But do you really know what it is? In this article, we'll take you on a journey through the world of machining and give you an insight into the skills that have shaped modern industry...