arrange in order

How robotic automated riveting and welding processes enhance production efficiency and consistency

The Riveting and Welding Revolution Amidst the Automation Wave Against the backdrop of global manufacturing advancing towards Industry 4.0 and “Made in China 2025”, traditional riveting and welding processes—historically reliant on manual skills—are undergoing a profound automation transformation. Robotic automated riveting and welding systems, with their exceptional repeatability, stable...

Laser welding vs. conventional welding: How to choose the right technology for your project?

In the field of metal fabrication and machining, choosing the right welding technology is a critical part of determining the success or failure of a project. Laser welding and conventional welding (e.g. MIG/MAG, TIG) are the two dominant technologies, but they differ significantly in terms of productivity, cost and final quality. As a leading company...

Rivet Welding Processes and Rivet Welding Plants: the core strength of modern metal structure manufacturing (a reliable rivet welding plant should be well-equipped and quality assured)

Rivet Welding Processing and Rivet Welding Plant: the core strength of modern metal structure manufacturing From the sturdy skeleton of heavy machinery to the complex components of precision equipment, rivet welding processing has constructed a solid foundation for modern industrial manufacturing with its unique joining technology. In the field of industrial manufacturing, the reliability of joining technology and...

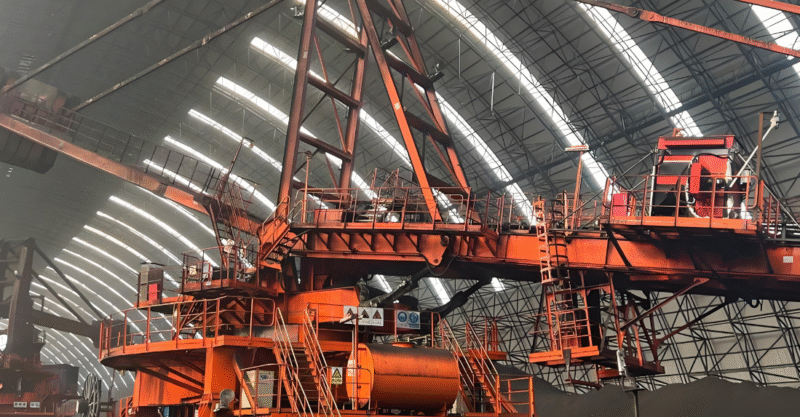

The whole process of intelligent transformation of old stacker reclaimer: practical analysis from technology selection to investment recovery (for “intelligent stacker reclaimer transformation technology programme and investment return analysis”)

When a large domestic port decided to carry out intelligent transformation of 12 stacker reclaimers with an average age of more than 15 years, there was a lot of internal controversy. The opponents made a calculation: the total budget for the transformation is 28 million, while the new equipment purchased is only 120 million, is the transformation worth it? Now, three years later, this remodelling...

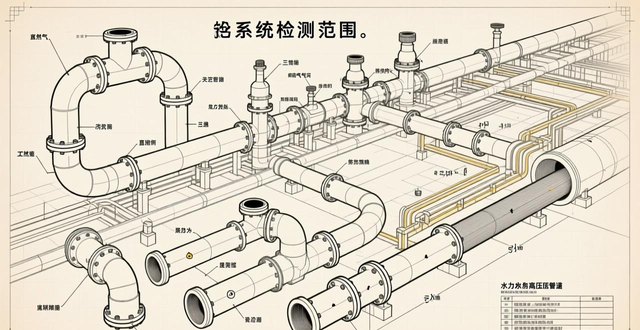

High Pressure Seal Testing Organisation, High Pressure Seal Inspection Report

12. Overall system sealing function test: Under simulated or near-actual working conditions, the entire pressure system (including vessels, pipelines, valves, instrumentation joints, etc.) is subjected to an integrated sealing performance test to assess the leakage level of the system in the linkage state.10

From welding, sheet metal to assembly - the full range of riveting and welding processing service process unveiled

Rivet Welding Process, Welding Sheet Metal Assembly One Stop, Full Service Article Outline: Introduction: Modern manufacturing requires integrated services. Revealing the complete journey of a part from drawing to finished product demonstrates the advantages of a one-stop shop. Step 1: Design and Engineering Review (Customer Collaboration from...

Intelligent mining new standard: 2026 mining excavator five intelligent system selection to avoid pit full strategy

Last month in Shanxi to participate in a smart mine seminar, encountered an interesting thing: two neighbouring coal mines, last year, all purchased a “smart excavator”. A year later, A mine's equipment into a “model project”, B mine's equipment is basically in the “intelligent dormant” state - in addition to the base...

How to Select a Reliable Aluminium Alloy Riveting and Welding Service Provider? Six Key Evaluation Criteria

The Importance of Selecting Aluminium Alloy Riveting and Welding Service Providers Aluminium alloys, renowned for their lightweight properties, corrosion resistance, and high strength, find extensive application across aerospace, automotive manufacturing, and shipbuilding industries. However, welding aluminium alloys is prone to issues such as porosity, hot cracks, and deformation, demanding significant technical expertise from processing service providers...

How many kinds of rivet welding operation methods? Comprehensive analysis of the 5 mainstream processes and applications

Want to know the riveting in the end there are several methods of operation? This article explains in detail the hot riveting, cold riveting, pulling riveting, striking core riveting and ring groove riveting 5 process principles, steps and applicable scenarios, an article to read and understand! How many ways to operate riveting? An article to master all the mainstream process Introduction: Briefly describe the riveting welding in steel...

Common Riveting and Welding Methods and Case Studies in Mechanical Equipment Maintenance and Modification

Repair Welding: The Art of Reviving Equipment Throughout the lengthy lifecycle of mechanical equipment, wear, corrosion, fatigue cracking, and even accidental damage are inevitable. Replacing entire units or major components is often prohibitively expensive and time-consuming. At such times, masterful riveting and welding repairs and modifications...