arrange in order

Core technology details: stainless steel and carbon steel riveting and welding processing technology comparison and industry applications

Introduction: Ask the question - Stainless steel and carbon steel are the most commonly used metal materials, how do they differ in riveting and welding processes? What are the consequences of making the wrong choice? Quick Facts on Material Properties: Stainless steel: corrosion resistance, high strength, easy to work harden, poor thermal conductivity. Carbon steel: low cost,...

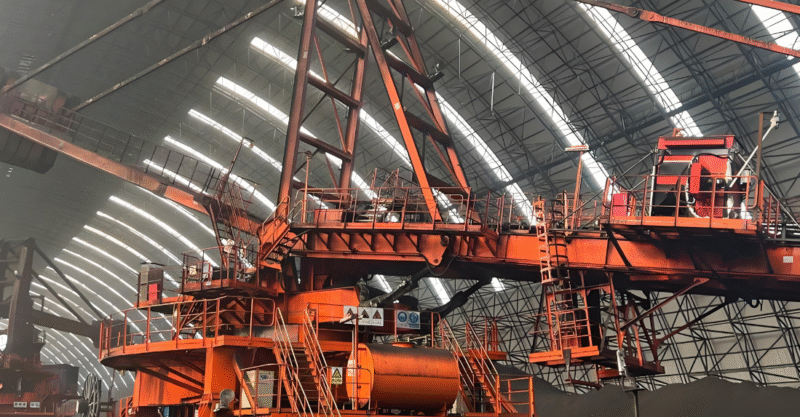

The whole process of intelligent transformation of old stacker reclaimer: practical analysis from technology selection to investment recovery (for “intelligent stacker reclaimer transformation technology programme and investment return analysis”)

When a large domestic port decided to carry out intelligent transformation of 12 stacker reclaimers with an average age of more than 15 years, there was a lot of internal controversy. The opponents made a calculation: the total budget for the transformation is 28 million, while the new equipment purchased is only 120 million, is the transformation worth it? Now, three years later, this remodelling...

Slewing Bearing In-Depth Repair Guide: 126 Days from Early Warning to Repair Completion (for “Diagnosis and Repair Programme for Slewing Bearings in Stockpile Reclaimers”)

When the slewing bearing of the No. 8 stacker reclaimer in a port in Liaoning Province made its first noise, maintenance team leader Xiao Wang didn't pay much attention to it. After all, this equipment has been running for 11 years, a little sound “normal”. Three months later, the slewing appeared obvious stalling, they just stopped to check. After dismantling the machine, everyone...

Stacker selection practice: wheeled and arm seven-dimensional comparison and five selection traps

When a large power plant in the south expanded its coal yard, there was a heated debate on equipment selection. One side insisted on the use of mature technology arm stacker reclaimer, the other side is pushing for more flexible wheeled stacker reclaimer. The debate lasted three months, and finally the deputy chief engineer of the power plant, Lao Chen, made the decision: “Let's go and see the real...

Intelligent mining new standard: 2026 mining excavator five intelligent system selection to avoid pit full strategy

Last month in Shanxi to participate in a smart mine seminar, encountered an interesting thing: two neighbouring coal mines, last year, all purchased a “smart excavator”. A year later, A mine's equipment into a “model project”, B mine's equipment is basically in the “intelligent dormant” state - in addition to the base...

Into the manufacturing workshop: mining hydraulic excavator five core process reveal and quality identification know-how

Three years ago, I accompanied a coal mining procurement team on a tour of two excavator manufacturing plants. The first factory had a shiny floor, brand new equipment, and a red carpet on the tour path; the second factory had grease stains on the floor, the equipment looked used, and the workers were hammering on the jigs and fixtures. Coal mine...

Procurement director must read: large mining excavator seven core parameters depth comparison and avoid pit guide

Purchasing Director must read: large mining excavator seven core parameters depth comparison and pit avoidance guide Full Article: Last week and an open-pit coal mine in Inner Mongolia, the equipment minister Lao Zhang dinner, he lamented: “Last year the procurement of that 380-tonne mining excavator, parameter table to see three months, the results are still off...

What equipment do you need to start a riveting factory?2025 essential equipment investment list (with shopping advice)

Planning to start a riveting factory? This article provides you with a full list of all the equipment needed from a small workshop to a medium-sized factory, including undercutting, moulding, riveting, welding and auxiliary equipment, along with key points for purchasing, to help you plan your investment wisely. The Ultimate Guide to Rivet Welding Plant Equipment: Essential for Investing in a ...

What are the operating methods of rivet welding? A quick comparison of all technical features in one table

Quickly check all the operational methods of riveting! We list the definitions, tools, strengths, and applicable scenarios of hot riveting, cold riveting, and pull riveting techniques in a clear comparative table to help you make quick decisions. All Operating Methods of Riveting at a Glance & Quick Lookup Guide INTRODUCTION: Cutting straight to the chase, mentioning...

The Road to Mastery: 10 Must-Watch Riveting Techniques Video Explained to Solve Your Practical Problems

Say goodbye to rivets that don't hold or look good! This article through the advanced skills video explanation, in-depth solution to riveting eccentricity, deformation, sealing, dissimilar materials connection and other difficult problems, to enhance your craft level. Riveting advanced skills video explanation: from “can do” to “do fine” Introduction: For those who have mastered the basics,...