arrange in order

Rivet Welding and Rivet Welding Manufacturing: Reliable Solutions for Modern Industrial Connections (Rivet Welding Processes Demonstrate Excellent Adaptability to Different Materials and Working Conditions)

Rivet Welding and Rivet Welding Manufacturing: Reliable Solutions for Modern Industrial Connections From the steel structure of a cross-sea bridge to an aerospace vehicle, from the skeleton of a heavy machine to the casing of a precision instrument, riveting and welding manufacturing technology has become an indispensable connecting process for modern industry due to its unique structural advantages. In the industrial...

Slewing Bearing In-Depth Repair Guide: 126 Days from Early Warning to Repair Completion (for “Diagnosis and Repair Programme for Slewing Bearings in Stockpile Reclaimers”)

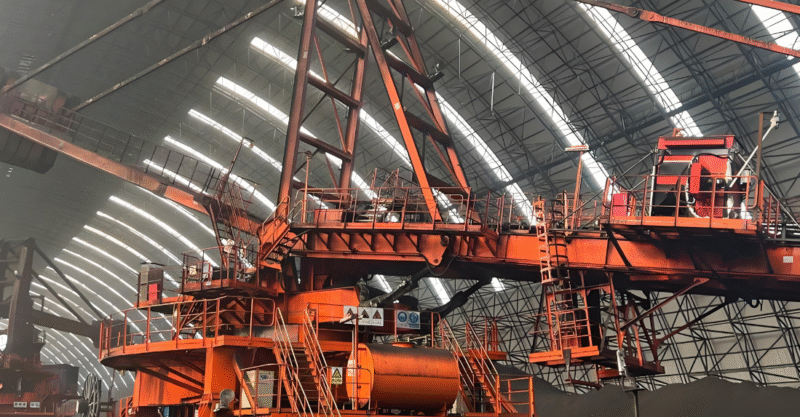

When the slewing bearing of the No. 8 stacker reclaimer in a port in Liaoning Province made its first noise, maintenance team leader Xiao Wang didn't pay much attention to it. After all, this equipment has been running for 11 years, a little sound “normal”. Three months later, the slewing appeared obvious stalling, they just stopped to check. After dismantling the machine, everyone...

Application of Dissolution Technology in Rivet Welding: Principles, Processes and Case Studies

Dissolution Technology in Rivet Welding: Principles, Processes and Case Studies When dissolution ceases to be a separation and becomes a bridge for connection, the process boundaries of manufacturing are being redefined In the field of rivet welding, dissolution is much more than a simple material separation process. From the formation of solder alloys...

How robotic automated riveting and welding processes enhance production efficiency and consistency

The Riveting and Welding Revolution Amidst the Automation Wave Against the backdrop of global manufacturing advancing towards Industry 4.0 and “Made in China 2025”, traditional riveting and welding processes—historically reliant on manual skills—are undergoing a profound automation transformation. Robotic automated riveting and welding systems, with their exceptional repeatability, stable...

Laser welding vs. conventional welding: How to choose the right technology for your project?

In the field of metal fabrication and machining, choosing the right welding technology is a critical part of determining the success or failure of a project. Laser welding and conventional welding (e.g. MIG/MAG, TIG) are the two dominant technologies, but they differ significantly in terms of productivity, cost and final quality. As a leading company...

How many kinds of rivet welding operation methods? Comprehensive analysis of the 5 mainstream processes and applications

Want to know the riveting in the end there are several methods of operation? This article explains in detail the hot riveting, cold riveting, pulling riveting, striking core riveting and ring groove riveting 5 process principles, steps and applicable scenarios, an article to read and understand! How many ways to operate riveting? An article to master all the mainstream process Introduction: Briefly describe the riveting welding in steel...

HVAC - Installation and Inspection of Air Conditioning Ducts and Smoke Evacuation Systems (II)

HVAC - Installation and Inspection of Air Conditioning Ducts and Smoke Evacuation Systems (II)

Rivet Welding Processes and Rivet Welding Plants: the core strength of modern metal structure manufacturing (a reliable rivet welding plant should be well-equipped and quality assured)

Rivet Welding Processing and Rivet Welding Plant: the core strength of modern metal structure manufacturing From the sturdy skeleton of heavy machinery to the complex components of precision equipment, rivet welding processing has constructed a solid foundation for modern industrial manufacturing with its unique joining technology. In the field of industrial manufacturing, the reliability of joining technology and...

The whole process of intelligent transformation of old stacker reclaimer: practical analysis from technology selection to investment recovery (for “intelligent stacker reclaimer transformation technology programme and investment return analysis”)

When a large domestic port decided to carry out intelligent transformation of 12 stacker reclaimers with an average age of more than 15 years, there was a lot of internal controversy. The opponents made a calculation: the total budget for the transformation is 28 million, while the new equipment purchased is only 120 million, is the transformation worth it? Now, three years later, this remodelling...

Rivet Welding and Dissolution Technology Shape Manufacturing Future Together

Rivet Welding Welding and Dissolution Technologies Shape the Future of Manufacturing Together The Next Chapter of Manufacturing is Being Written in a Duo of Material Connections and Separations Manufacturing stands at a turning point. Traditional process boundaries are blurring, replaced by a deep convergence of technologies. In the midst of this transformation...