arrange in order

The Ultimate Guide to Rivet Welding Processing: A Complete Analysis of Processes, Applications and Options (What is Rivet Welding Processing?) Core Concepts Explained)

The Ultimate Guide to Rivet Welding Machining: a Complete Explanation of Processes, Applications and Options INTRODUCTION At the heart of modern industrial manufacturing, riveting and welding machining continues to play an irreplaceable role as a fundamental and vital joining technique. Whether you are a corporate buyer looking for reliable machining services, or...

Welding defects: How to avoid weld failures due to “dissolution” problems?

Welding defects: How to avoid weld failures due to “dissolution” problems? When a welded joint fails, often the problem is not in the material itself, but in the microscopic “dissolution” process. Understanding and controlling dissolution is the key to eliminating common weld defects and improving product yields...

Procurement director must read: large mining excavator seven core parameters depth comparison and avoid pit guide

Purchasing Director must read: large mining excavator seven core parameters depth comparison and pit avoidance guide Full Article: Last week and an open-pit coal mine in Inner Mongolia, the equipment minister Lao Zhang dinner, he lamented: “Last year the procurement of that 380-tonne mining excavator, parameter table to see three months, the results are still off...

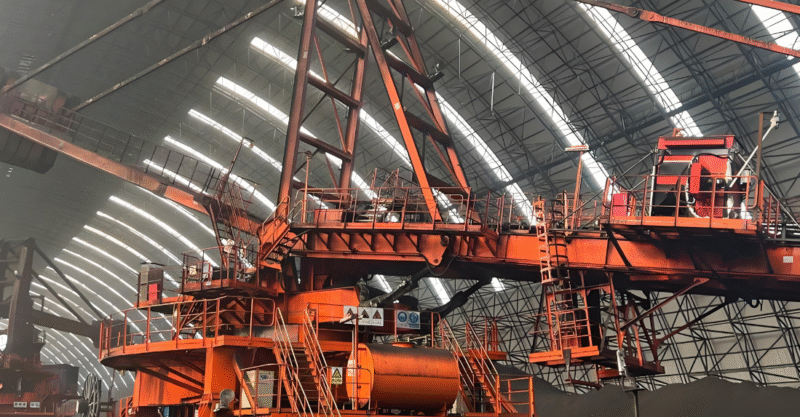

The whole process of intelligent transformation of old stacker reclaimer: practical analysis from technology selection to investment recovery (for “intelligent stacker reclaimer transformation technology programme and investment return analysis”)

When a large domestic port decided to carry out intelligent transformation of 12 stacker reclaimers with an average age of more than 15 years, there was a lot of internal controversy. The opponents made a calculation: the total budget for the transformation is 28 million, while the new equipment purchased is only 120 million, is the transformation worth it? Now, three years later, this remodelling...

Application of Dissolution Technology in Rivet Welding: Principles, Processes and Case Studies

Dissolution Technology in Rivet Welding: Principles, Processes and Case Studies When dissolution ceases to be a separation and becomes a bridge for connection, the process boundaries of manufacturing are being redefined In the field of rivet welding, dissolution is much more than a simple material separation process. From the formation of solder alloys...

The future of rivet welding processing plant: automation and intelligent transformation (automation and intelligence is not a question of choice, but rivet welding processing plant survival and development of the road)

The Future of Rivet Welding Processing Plant: Automation and Intelligent Transformation 1 Industry Changes and Opportunities As a basic service of the manufacturing industry, riveting and welding processing is experiencing profound technological changes. The traditional welding and riveting process is gradually integrated with automation and digital technology, promoting the riveting and welding processing plant to a higher...

Dissolving and Welding: Uncovering the Science and Key Processes of Weld Formation

Dissolving and Welding: The Science and Critical Processes of Weld Formation In the wonderful world of welding, “dissolving” is a critical physico-chemical process that directly determines the strength and reliability of the weld. Many people mistakenly think that welding is simply “melting and bonding”, but...

Argon arc welding, two bonded welding, plasma welding, laser welding, how to choose?

First of all, to just come in the friend to introduce the introduction of argon arc welding, two bonded welding, plasma welding, laser welding, the working principle of each and its advantages. Convenient to learn or to enter the processing industry bosses to choose. Argon arc welding argon arc welding arc using high-pressure breakdown of the arc starting method

Dissolution control and quality management in advanced welding technology (dissolution characteristics and control methods in major welding processes)

Dissolution Control and Quality Management in Advanced Welding Technology 1 Overview of Welding Technology and the Role of Dissolution in Welding Welding technology, as one of the core processes in the modern manufacturing industry, is used to make permanent connections by bringing the materials to an inter-atomic or inter-molecular bonding through various heat sources. In this process, the...

Core technology details: stainless steel and carbon steel riveting and welding processing technology comparison and industry applications

Introduction: Ask the question - Stainless steel and carbon steel are the most commonly used metal materials, how do they differ in riveting and welding processes? What are the consequences of making the wrong choice? Quick Facts on Material Properties: Stainless steel: corrosion resistance, high strength, easy to work harden, poor thermal conductivity. Carbon steel: low cost,...