arrange in order

Advancing Towards Industry 4.0 – The Current State of Intelligent and Automated Applications in Machining Workshops

The Fourth Industrial Revolution in Workshop Practice As “Industry 4.0” transitions from concept to reality, machining workshops are undergoing the most profound transformation since the advent of CNC technology. This revolution represents not merely a technological upgrade, but a fundamental restructuring of production philosophies, organisational methodologies, and value creation models. Rooted...

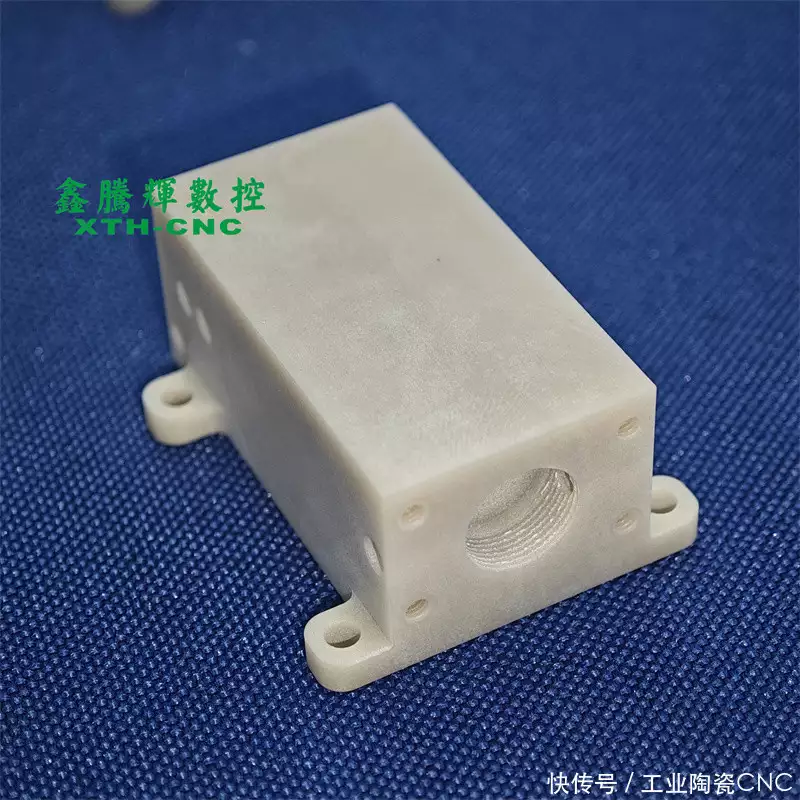

陶瓷雕铣机让复杂陶瓷零件加工不再 “卡脖子”

在工业陶瓷加工领域,“复杂零件” 始终是横在加工厂面前的一道难关。随着光伏、电子、新能源等行业的快速发展,带有异形曲面、多孔位、深腔窄缝等复杂结构的陶瓷零件需求激增

A Comprehensive Guide to Machining and Machining: The Art of Precision Manufacturing from Traditional to CNC

A comprehensive guide to machining and machining: the art of precision manufacturing from traditional to CNC Precision and efficiency are key in manufacturing, and machining is the core technology to achieve this. This article will take you on a deep dive into the world of machining, from traditional manual machining to modern CNC technology...

Machining outsourcing processing network full strategy: choose the right platform, let the order come to you

Machining outsourcing processing network which is good?2025 mainstream platform review and use guide | Meta Description (description tag): Don't know how to choose machining outsourcing processing network? This article is an in-depth review of Alibaba 1688, Huicong.com and other mainstream platforms, teaching you how to efficiently le...

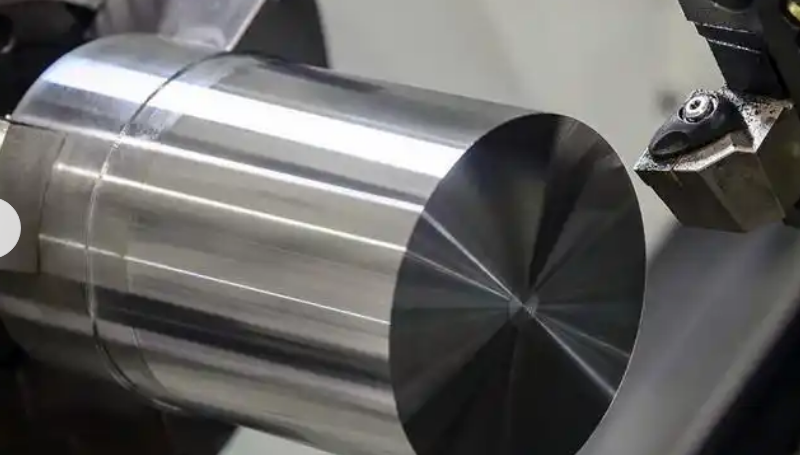

Turn-mill lathes: efficient solutions for modern manufacturing

Versatility: Turning and milling compound lathe can carry out turning, milling, drilling, tapping and other machining operations, which reduces the number of workpiece clamping and machining time. As an advanced processing equipment, mill-turning lathe is characterised by its versatility, high precision and high efficiency.

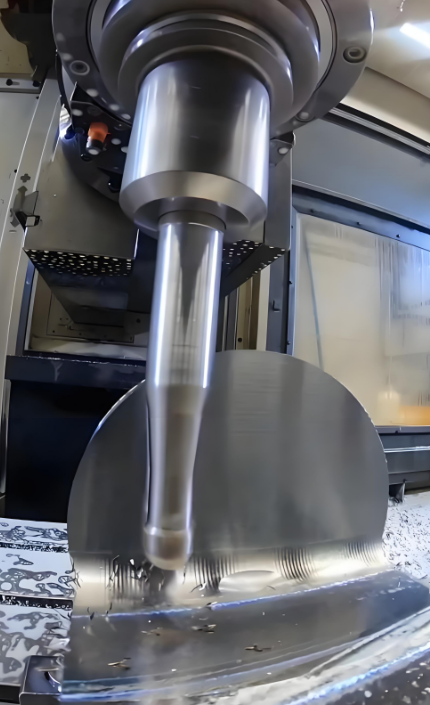

Cutting and Milling: Core Technologies and Innovative Applications for Modern Manufacturing (Analysis of Milling and Grinding: Fusion of Efficiency and Precision Innovation)

Cutting and Milling: Core Technologies and Innovative Applications for Modern Manufacturing From automotive engines to aerospace precision components, from medical devices to core components of smart devices, cutting and milling technologies have built the cornerstone of modern industrial manufacturing. In the global manufacturing intelligent...

The Ultimate Guide to Machining: From Principles and Processes to Modern Applications, Read the Heart of Precision Manufacturing in One Article

Machining is a cornerstone technology of modern manufacturing. This article comprehensively analyses the core principles, mainstream processes, technological evolution and industry applications of machining, providing you with a professional framework and decision-making guide for choosing machining services. Article Body Introduction: When Design Meets Solid - How Machining ...

High Rework Rates in Machinery Manufacturing Plants? 3 Segments to Control Steel Suppliers

The fatal pain point of machinery manufacturing: raw material quality fluctuations, low processing pass rate, rework costs remain high! A machine tool manufacturer has planted this heel - due to the lack of control of steel suppliers, raw material hardness, toughness indicators fluctuating, parts and components processing pass rate of 82% only!