arrange in order

The Complete Guide to Machining Plants and Lathes: Process, Selection and Cost Analysis (Core Concept Analysis: Machining Plants and Lathes)

An all-round guide to machining plants and lathe machining: process, selection and cost analysis Introduction In today's manufacturing landscape, machining plants, as the core link in the industrial chain, have a direct relationship between their technology and capabilities and the quality and performance of various products. Among them, lathe machining as a basic...

CNC Machining and Boring: The Core Force Driving High-Precision Development in Modern Manufacturing

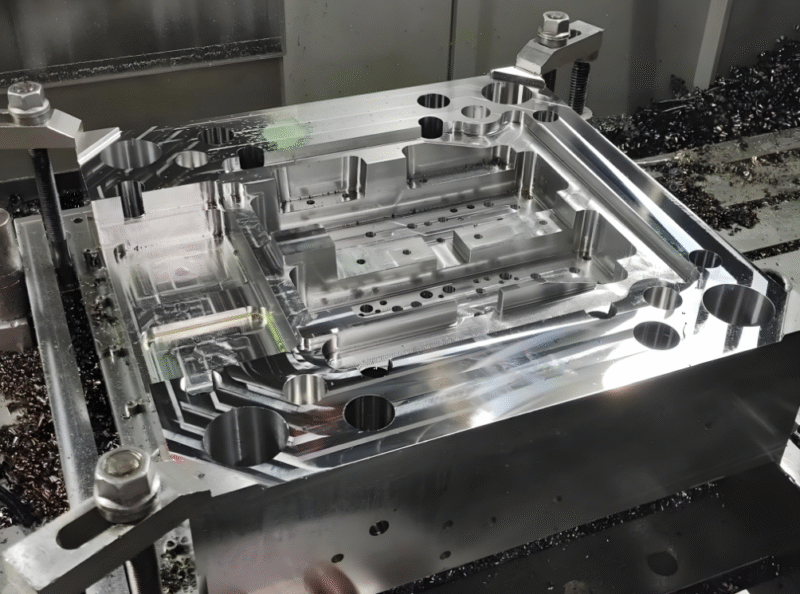

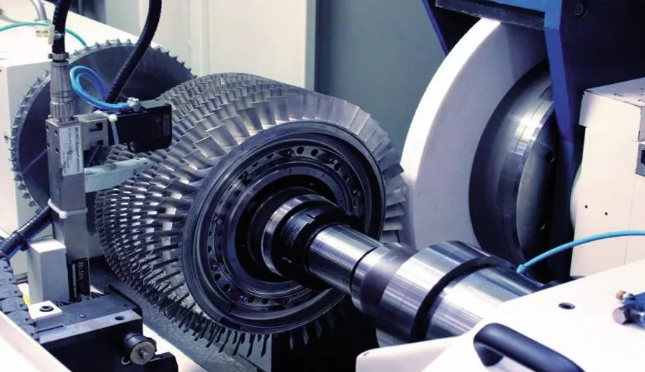

CNC Machining and Boring Machine Machining: The Core Force Driving the Development of Modern Manufacturing with High Precision Under the background of the global manufacturing industry's transformation to intelligence and precision, CNC machining has become a key technology for industrial upgrading by virtue of its high efficiency and accuracy; while boring machine machining, as a CNC machining...

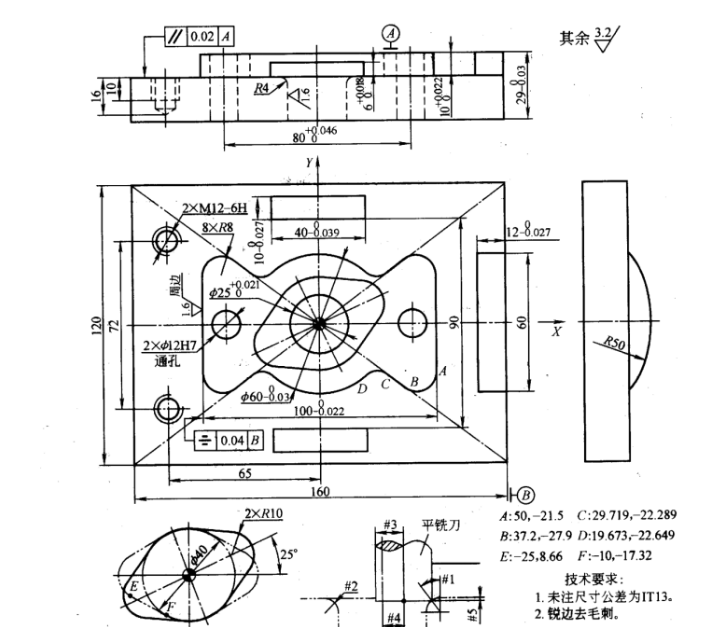

Machining technology: a core pillar of modern manufacturing (key technical parameters and quality control of machining)

Machining Technology: The Core Pillar of Modern Manufacturing From tiny medical devices to giant power generation equipment, 80% industrial products around the world cannot be separated from the support of machining technology. Machining (referred to as machining) refers to the cutting, shaping and other operations of workpieces through mechanical equipment,...

Machining Quality Control and Industry Trends (Building a Comprehensive Machining Quality Management System)

The pursuit of excellence: machining quality control and industry development trend Introduction In an increasingly competitive market, "machining" quality is the lifeline of enterprises. This article focuses on the total quality management system of machining, process optimisation, and looks forward to the policy and technological dual-wheel drive,...

Machining and materials science: how to select optimal cutting solutions for different materials?

Machining is not static. This article takes an in-depth look at how to select the right tools, cutting fluids and parameters to optimise results when machining aluminium alloys, stainless steel, titanium alloys and engineering plastics. Successful machining is half dependent on equipment and processes, and the other half is dependent on understanding the material specific...

How to choose a reliable machining manufacturer?5 core elements to help you avoid pitfalls and ensure the quality of parts

How to Choose a Reliable Machining Manufacturer?5 Core Elements to Help You Avoid Pitfalls and Ensure Part Quality Finding a reliable machining manufacturer is a critical step in the success of a project as it moves forward. The wrong choice can lead to a host of problems such as substandard parts, delivery delays, cost overruns...

Machining Automation Trends 2025: How Robots Can Boost Productivity

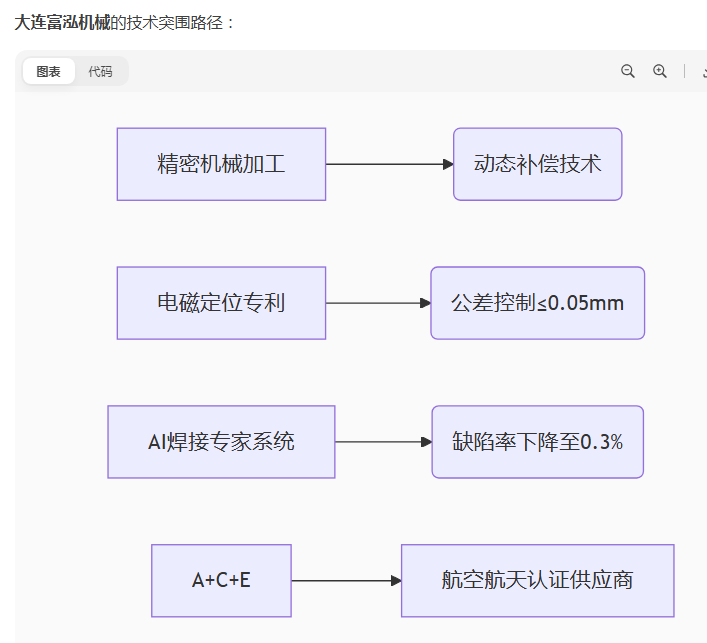

Driven by the wave of intelligence, robotics is reshaping the production model and efficiency pattern of the machining industry at an unprecedented speed. In the workshop of a mechanical enterprise in Dalian Fuhong, intelligent equipment is running efficiently: it can complete the whole process of processing 18,000 brake discs per hour....

Riveting and machining technology innovation in the transformation of global manufacturing: automation, lightweighting and precision breakthroughs

Riveting and Machining Technology Innovation in Global Manufacturing Transformation: Automation, Lightweighting and Precision Breakthroughs (Dalian Furhong Machinery - Aerospace Riveting Technology Innovator | CNC/Automatic Drilling and Riveting Solutions) 1 Technology Transformation in Global Manufacturing: Riveting and Machining Pillar Position in Industry 4.0...

Machining & Machining Services Specialists - Precision Manufacturing Solutions

Machining & Machining Services Specialists - Precision Manufacturing Solutions Why Choose Our Machining Services? In today's competitive manufacturing environment, precision machining is a key factor in business success. With 20 years of professional machining experience, we offer a full range of...

Machining Basics Explained: From Traditional Processes to Modern Applications

Explore the world at the heart of machining. This article details the principles, characteristics and applicable scenarios of traditional machining processes such as turning, milling, drilling and grinding to help you choose the most appropriate machining method for your project. Machining, the cornerstone of manufacturing, is the use of cutting tools through mechanical forces...