arrange in order

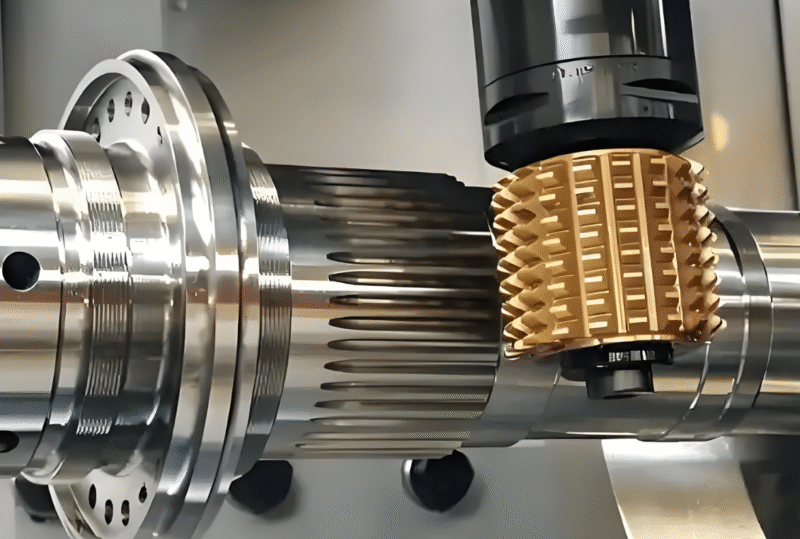

What is machining (machining)? A look at all the core processes of CNC machining, turning, milling, drilling and grinding

In manufacturing and product development, “machining” (often referred to simply as “machining”) is an indispensable cornerstone. But do you really know what it is? In this article, we'll take you on a journey through the world of machining and give you an insight into the skills that have shaped modern industry...

Recommended Semiconductor Parts Processing, Fuhong Technology Precision Manufacturing to Meet High Cleanliness Requirements

Semiconductor parts processing recommended, Panasonic precision manufacturing to meet the high cleanliness requirements, equipment, customers, service, high-end, Xuancheng, EDM, cleanliness

Machining (machining): core technologies and applications for modern manufacturing

Machining (machining): the core technology and application of modern manufacturing industry Machining (machining for short) is a manufacturing process in which workpieces are cut, shaped, etc. by mechanical equipment to obtain the desired shape, size and surface quality. As the basic process of manufacturing, machining...

Machining and materials science: how to select optimal cutting solutions for different materials?

Machining is not static. This article takes an in-depth look at how to select the right tools, cutting fluids and parameters to optimise results when machining aluminium alloys, stainless steel, titanium alloys and engineering plastics. Successful machining is half dependent on equipment and processes, and the other half is dependent on understanding the material specific...

Research on the method of detecting surface texture defects on machined parts

Machining parts surface texture defects detection of the method of research.doc, machining parts surface texture defects detection of the method of research Abstract: With the improvement of China's industrial development level, the degree of modernisation of industrial production is increasingly high.

5 Advantages of Precision Machining: Why Choose a Professional Processor? (Professional machining can significantly increase productivity by optimising machining paths and using automated equipment)

5 Advantages of Precision Machining: Why Choose a Professional Fabricator? 1 INTRODUCTION: THE VALUE OF PRECISION MACHINING In a competitive manufacturing environment, precision machining has become a key determinant of product quality and performance. Choosing a professional machine shop not only ensures that parts...

Machining solutions and cost analyses for prototyping small-lot, multi-variety products

In the era of rapid product innovation, “fast” and “accurate” are the core demands of prototyping. When your needs are for small quantities (from a few to hundreds of pieces) and large varieties (multiple design versions or different parts), the traditional scale production model is no longer applicable. How do you find a way to guarantee quality...

Role, methods and process characteristics of heat treatment

Heat treatment is a thermal process in which steel is heated to a predetermined temperature in the solid state, held at that temperature for a certain period of time, and then cooled down at a certain rate. It is widely used in the machinery manufacturing industry, and this paper

Precision Machining Services in China: The First Choice for Cost Optimisation and Quality Upgrade for Japanese Companies

Precision Machining Services in China: The First Choice for Cost Optimisation and Quality Upgrading for Japanese Enterprises Dear Japanese Manufacturing Partners, Are you looking for a machining solution that combines Japanese quality standards with cost competitiveness? China machining OEM service is becoming more and more Japanese companies...

How to choose a reliable machining manufacturer?5 core elements to help you avoid pitfalls and ensure the quality of parts

How to Choose a Reliable Machining Manufacturer?5 Core Elements to Help You Avoid Pitfalls and Ensure Part Quality Finding a reliable machining manufacturer is a critical step in the success of a project as it moves forward. The wrong choice can lead to a host of problems such as substandard parts, delivery delays, cost overruns...