arrange in order

What are the machining methods and characteristics of machining, 7 mainstream processes and selection guide

Explore the world of machining! This article is a deep analysis of turning, milling, drilling, boring, grinding, wire cutting, laser machining 7 mainstream ways, a detailed comparison of their processing characteristics, precision, applicable materials, to help you choose the best process for the project. Panorama of machining methods: in-depth analysis of the characteristics and practical selection ...

Chapter 5 - Measurement Technology in Precision Machining Courseware.ppt

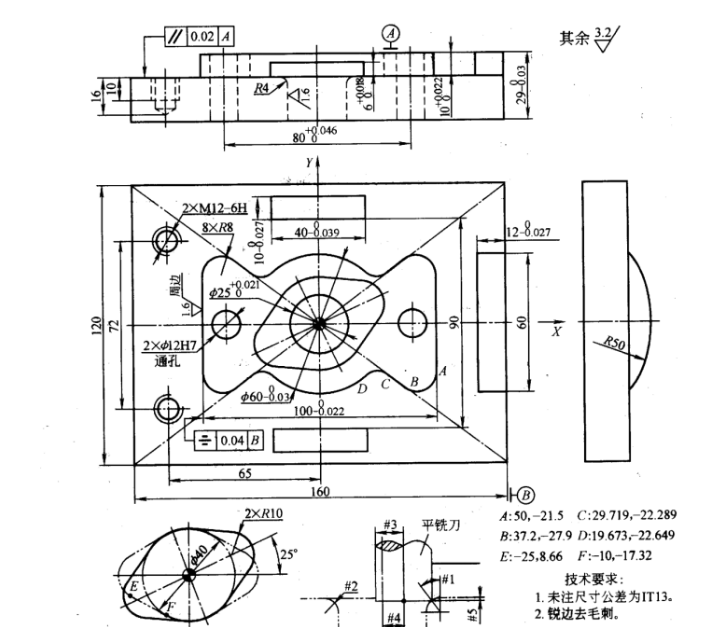

Precision and Ultra-precision Machining TechnologyPrecision and Ultra-precision Machining TechnologyTeacher,Li SonghuaTeacher,Li Songhua,Overview of Precision Measurement TechnologyOverview of Precision Measurement Technology,Measurement DatumMeasurement Datum,Measurement of Straightness, Flatness and PerpendicularityStraightness

Global Perspectives: Internationalisation Strategies for Heavy Equipment Manufacturers (Discusses how machinery and equipment manufacturers can develop and implement successful internationalisation strategies.)

Global Perspective: Internationalisation Strategy of Heavy Equipment Manufacturers 1 Introduction: From Local King to Global Player For Chinese heavy equipment manufacturers, globalisation is no longer an optional option, but an inevitable path for survival and development. With a complete industrial system, strong...

Aluminium Alloy vs Stainless Steel – Characteristics and Challenges of Different Metallic Materials in Precision Machining

How Material Selection Determines Machining Success In the field of precision machining, material selection is not merely a cost consideration but a core factor determining part performance, machining efficiency, and final quality. Aluminium alloys and stainless steel, as two of the most commonly used metallic materials, each possess unique physical properties...

Technical difficulties and solutions for the machining of high-precision parts

High-precision parts machining technical difficulties and solutions High-precision parts machining is an important technical link in the modern manufacturing industry, widely used in aerospace, automotive manufacturing, machinery and equipment, as well as electronic products and other fields. With the development of industrial automation and intelligent manufacturing

Looking for top-notch machining services? We provide high-precision and high-quality CNC machining solutions, serving the European, American and Japanese markets. Strict quality control and instant quotes to meet your custom machining needs

Looking for top-notch machining services? We provide high-precision and high-quality CNC machining solutions, serving the European, American and Japanese markets. Strict quality control and instant quotes to meet your custom machining needs. (The meta description succinctly and powerfully contains all keywords and clearly...

A guide to the best machining outsourcing apps for 2025: how to optimise your supply chain with digital platforms

Looking for a machining outsourcing app?This article reviews the features of mainstream platforms and reveals how to use apps to efficiently publish requirements, intelligently match suppliers, manage orders and deliveries, and revolutionise your traditional outsourcing model. In the increasingly competitive manufacturing industry, efficient and transparent management of outsourcing...

Sheet metal working erp system: a tool for improving productivity

Sheet metal processing erp system: a tool to improve productivity Sheet metal processing is a manufacturing process that produces a variety of metal parts or products by bending, cutting, punching, and other processing operations on sheet metal using mechanical pressure or pressure machines.

CNC Machining and Boring: The Core Force Driving High-Precision Development in Modern Manufacturing

CNC Machining and Boring Machine Machining: The Core Force Driving the Development of Modern Manufacturing with High Precision Under the background of the global manufacturing industry's transformation to intelligence and precision, CNC machining has become a key technology for industrial upgrading by virtue of its high efficiency and accuracy; while boring machine machining, as a CNC machining...

Machining process standards explained: ISO, GB, ASME, how to ensure global manufacturing consistency?

Machining process standards are the universal language of quality. This article explains how ISO, GB, ASME and other core standards regulate dimensional and geometric tolerances, surface finishes, and ensure global interchangeability and reliability of components. Machining process standards: the cornerstone of global manufacturing...