arrange in order

Mastering core processes: How machining is shaping the cornerstones of modern manufacturing

Seeing Machining: the heart of manufacturing from drawing to finished product Machining, the cornerstone of manufacturing, is essentially a dance of materials, precision and efficiency. When you get your hands on a metal part with a superb finish and a tight fit, do you ever wonder how it got from a rough piece of raw material...

GBT1008-2008 Basic Terminology for Machining Process Equipment (2025 Edition) In-depth Analysis.pptx

GBT1008-2008 Basic Terminology for Machining Process Equipment (2025 Edition) In-depth Analysis.pptx

Machining technology: a core pillar of modern manufacturing (key technical parameters and quality control of machining)

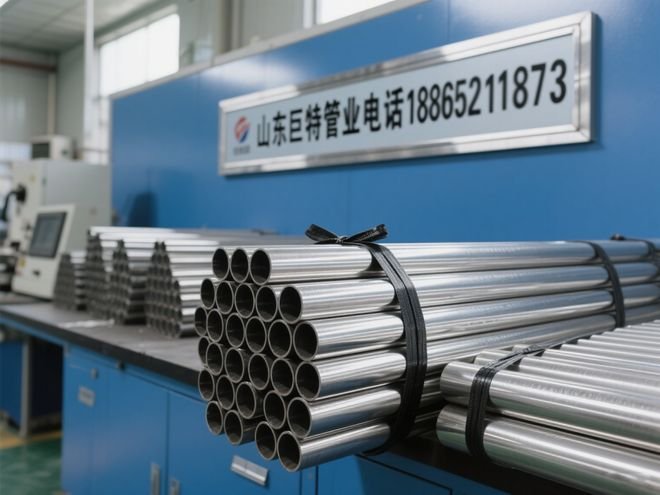

Machining Technology: The Core Pillar of Modern Manufacturing From tiny medical devices to giant power generation equipment, 80% industrial products around the world cannot be separated from the support of machining technology. Machining (referred to as machining) refers to the cutting, shaping and other operations of workpieces through mechanical equipment,...

What is CNC machining? A comprehensive explanation of the precision and efficiency revolution in modern manufacturing.

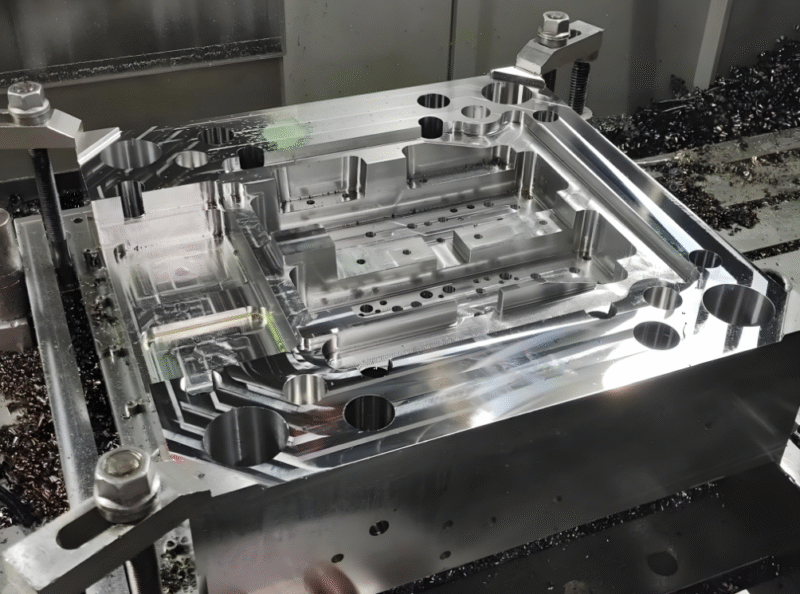

An in-depth look at CNC machining technology. From CNC principles and G-code to machining centres, this article explores how CNC machining enables the automated production of complex parts with high precision and efficiency. If you're interested in modern manufacturing, there's no getting around the fact that CNC machining is at the heart of...

Detailed Boring Process: Process Analysis from Rough Boring to Finish Boring

01 Boring Standard boring, as an integral part of a machining centre, is designed to ensure the dimensional and form accuracy of the hole system, thereby correcting errors that may have arisen in previous processes. This type of machining is mainly used for critical mating holes or support holes in machine parts.

Machining Quality Control and Industry Trends (Building a Comprehensive Machining Quality Management System)

The pursuit of excellence: machining quality control and industry development trend Introduction In an increasingly competitive market, "machining" quality is the lifeline of enterprises. This article focuses on the total quality management system of machining, process optimisation, and looks forward to the policy and technological dual-wheel drive,...

The essential difference between 3D printing and traditional machining and how to choose?

At the crossroads of today's product development and manufacturing, designers and engineers are often faced with a critical decision: should they use 3D printing or traditional machining (CNC)? Both are powerful technologies for turning digital models into solid parts, but their philosophies, processes and areas of application are very different...

Ranking of reliable CNC machining regular manufacturers, see which companies have a good reputation

In today's era of booming manufacturing, there is a growing demand for CNC machining services. Whether it's industrial production, automotive manufacturing, medical devices, home furnishings, or other fields, high-quality CNC machining products are indispensable. So.

Gear Machining: Focus on Non-standard Gear Processing, Adding New Power to Intelligent Manufacturing

Gear Machining: Focus on Non-Standard Gear Processing, Adding New Power to Intelligent Manufacturing In the architecture of modern industry, gears play a key role in the transmission of power and motion, and their applications are extremely broad, covering automotive manufacturing, aerospace, robotics, and medical equipment, etc....